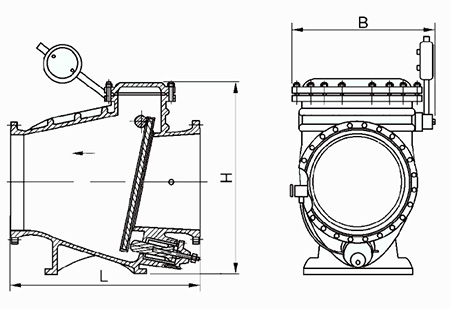

The micro resistance slow closing check valve is mainly suitable for water supply and drainage pipelines. It is installed at the outlet of the water pump to prevent medium backflow and eliminate destructive water hammer, and effectively reduce the pressure of valve closing water hammer, ensuring the safe operation of the pipeline network. It has the characteristics of light valve disc, large opening, good energy-saving effect, low fluid resistance, water hammer elimination mechanism design, stable sealing performance, wear resistance, long service life, stable operation, no vibration, and no noise.

Item NO.:

XUVAL88-215Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1Valve Introduction

Valve model

Common models of micro resistance slow closing check valves include:

The hh44h series models include: hh44h-10, hh44h-10c, hh44h-16, hh44h-16c, hh44h-25, hh44h-40, hh44h-40c, hh44h-64c, hh44h-100c, khh44h, etc;

The hh44x series models include: hh44x-10, hh44x-10c, hh44x-10q, hh44x-16, hh44x-16q, hh44x-16p, hh44x-16c, hh44x-25, khh44x, etc;

The hh44z series models include: hh44z-10, hh44z-16, khh44z, etc;

The hh44t series models include: hh44t-10, hh44t-16, hh44t-25, khh44t, etc;

Performance parameters

The nominal diameter ranges from DN40 to DN900;

The nominal pressures mainly include 1.0MPa, 1.6MPa, and 2.5MPa, which are the same as the highest working pressure;

The working temperature is generally less than 80 ℃, and if the customer has special requirements, it can reach 200 ℃;

The suitable medium is generally water or weakly corrosive medium;

The material of parts generally includes cast iron, cast steel, stainless steel, etc.

Overall dimensions

| Nominal Pressure(MPa) | Nominal DiameterDN(mm) | Size(mm) | ||

| L | H | B | ||

|

1

1.6

2.5

|

40 | 200 | 300 | 220 |

| 50 | 230 | 300 | 270 | |

| 65 | 290 | 320 | 290 | |

| 80 | 310 | 354 | 300 | |

| 100 | 350 | 350 | 320 | |

| 125 | 400 | 380 | 340 | |

| 150 | 480 | 500 | 410 | |

| 200 | 500 | 580 | 450 | |

| 250 | 600 | 670 | 550 | |

| 300 | 700 | 700 | 580 | |

| 350 | 800 | 820 | 630 | |

| 400 | 900 | 920 | 700 | |

| 450 | 1000 | 950 | 800 | |

| 500 | 1100 | 1100 | 900 | |

| 600 | 1300 | 1200 | 990 | |

| 700 | 1400 | 1550 | 1120 | |

| 800 | 1500 | 1700 | 1300 | |

| 900 | 1700 | 1800 | 1350 | |

Previous :

Forged steel check valvenext :

Forged Steel Globe ValveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported