Brass globe valves are part of the globe valve family.Its main material is brass.

Item NO.:

XU061Lead Time:

35DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

YellowMOQ:

10PN16 Brass flange globe valve

Brass globe valves are part of the globe valve family.Its main material is brass.

Brass is also called copper-zinc alloy, most commonly known as sanqi brass, which is the ratio of zinc to pure copper.Because of its good mechanical properties and processing is widely drunk.Brass globe valves are widely used in Marine valves.Has the advantage that the ordinary globe valve does not have.Globe valves are valves with a shutoff valve (disc) moving along the center line of the seat.Depending on this movement of the disc, the variation of the seat orifice is proportional to the disc travel.Due to the relatively short stem opening or closing stroke of this type of valve, and the very reliable cutting function, and the seat port changes in a direct proportion to the stroke of the disc, it is very suitable for flow regulation.Therefore, this type of valve is ideal for cutting or regulating and throttling.

Once the disc of the globe valve is removed from the closed position, there is no longer contact between the seat and the disc sealing surface, thus its sealing surface mechanical wear is very small, so its sealing performance is very good, the disadvantage is that the sealing surface may be trapped between particles in the flow medium.But if the disc is made into a ball of steel or porcelain, this problem is solved.Since most globe valves have seats and discs that are relatively easy to repair or replace, and do not require the entire valve to be removed from the line during repair or replacement of the sealing element, this is ideal where the valve and line are welded together.

The minimum resistance of globe valves is also higher than that of most other types of valves due to the change in the direction of flow of media through such valves.However, this condition can be improved depending on the body construction and stem layout relative to the inlet and outlet channels.At the same time.Due to the small travel between the opening and closing of the globe disc, the sealing surface can withstand multiple opening and closing, so it is suitable for frequent switching occasions.

Globe valves can be used in most media flow systems.A variety of globe valves have been developed to meet the needs of petrochemical, electric power, metallurgy, urban construction, chemical and other departments.

The use of the globe valve is very common, but due to the large opening and closing torque, the length of the structure is long, usually the nominal diameter is limited to 250mm below, but there are to 400mm, but the selection should pay special attention to the direction of import and export.Generally 15Omm below the globe valve medium is mostly from the bottom of the disc inflow, and more than 2O0mm of the globe valve medium is mostly from the top of the disc inflow.This is due to consideration of the closing torque of the valve.In order to reduce the opening or closing torque, the globe valves above 2O0mm are generally equipped with internal or external bypass valves.

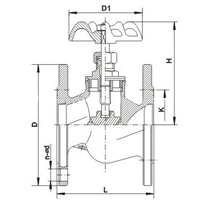

Brass Flange Globe Valve

size:1/2"- 4"

1.Nominal pressure: 1.6MPa

2.Suitable medium: water, non-causticity liquid and saturated steam

3.Working temperature: -80≤t≤180°C

4.Components and materials:

5.Handle: brass

6.Stem: brass

7.Washer: brass

8.Packing ring: teflon

9.Bonnet: brass

10.Disc: brass

11.Seal disc: NBR

12.Body: brass

13.Dimensions: through 1/2 to 1 inches

| Product name | Brass Flange Globe Valve |

| Material | Brass |

| Handle | Iron |

| Surface | Copper or natural |

| Size | 1/2"~4" |

| Usuage | Household |

| Thread | ISO228,ISO7/1 |

| Lead time | 15-30 Days after 30% deposit |

| DN | L | D | D1 | D2 | D6 | b | Do | H | H1 | Z-d | Weight(Kg) |

| 15 | 130 | 95 | 65 | 45 | - | 14 | 75 | 110 | 119 | 4-14 | 2 |

| 20 | 150 | 110 | 75 | 55 | - | 14 | 75 | 110 | 120 | 4-14 | 3 |

| 25 | 160 | 115 | 85 | 65 | - | 14 | 75 | 116 | 126 | 4-14 | 4 |

| 32 | 180 | 135 | 100 | 78 | - | 15 | 120 | 143 | 160 | 4-18 | 6.1 |

| 40 | 200 | 145 | 110 | 85 | - | 16 | 120 | 147 | 168 | 4-18 | 8.2 |

| 50 | 230 | 160 | 125 | 100 | - | 16 | 160 | 172 | 194 | 4-18 | 11 |

| 65 | 290 | 180 | 145 | 120 | - | 18 | - | - | - | 4-18 | 28 |

| 80 | 310 | 195 | 160 | 135 | - | 20 | - | - | - | 8-18 | 34 |

| 100 | 350 | 210 | 180 | 155 | - | 20 | - | - | - | 8-18 | 43 |

| 125 | 400 | 245 | 210 | 185 | - | 22 | - | - | - | 8-18 | 70 |

| 150 | 480 | 280 | 240 | 210 | 0 | 24 | - | - | - | 12-23 | 95 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough

subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.

Previous :

DIN PN 16 Cast Iron angle globe valvenext :

ANSI Class150 Class300 Stainless steel Flange globe valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported