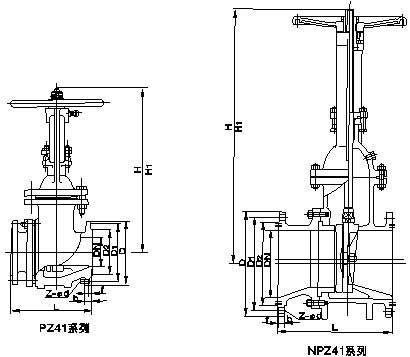

The slag discharge gate valve is suitable for cutting off or connecting the medium in the pipeline of the slurry discharge system of thermal power plants and hydraulic engineering. The suitable medium is the ash water mixture, and the slag water ratio of the slag water mixture is ≥ 1:15. Slag discharge gate valve PZ41H PN10~PN63: manual, flange connected, rising stem wedge type rigid single gate valve, valve seat sealing surface material is stainless steel, nominal pressure PN10~PN63, valve body material is gray cast iron (PZ41H-10 PZ41H-16), carbon steel (PZ41H-10C~63) slag discharge gate valve.

Item NO.:

XUVAL88-274Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1Main performance parameters

| Model | PN | Working pressure/MPa | Applicable temperature/℃ | Applicable Medium |

| PZ41H-10 | 10 | 1 | ≤100 | Ash slag water mixture (ash water ratio 1:1:5, maximum particle size ≤ 50mm) |

| PZ41H-16 | 16 | 1.6 | ||

| PZ41H-10C | 10 | 1 | ||

| PZ41H-16C | 16 | 1.6 | ||

| PZ41H-25 | 25 | 2.5 | ||

| PZ41H-40 | 40 | 4 | ||

| PZ41H-63 | 63 | 6.3 |

Material for main parts

| Model | Material | |||||

| Valve body, valve cover | Ram | Valve body sealing ring | Valve stem | Shim | Filler | |

| PZ41H-10 | Grey cast iron | Grey cast iron chrome plated stainless steel | Grey cast iron chrome plated stainless steel | Chromium stainless steel | Rubber asbestos board | Asbestos graphite |

| PZ41H-16 | ||||||

| PZ41H-10C | Carbon Steel | Carbon steel overlay welding of iron based alloys | Carbon steel overlay welding of iron based alloys | |||

| PZ41H-16C | ||||||

| PZ41H-25 | ||||||

| PZ41H-40 | ||||||

| PZ41H-63 | ||||||

Main overall dimensions

PZ41H PN10 slag discharge gate valve

| DN | L | D | D1 | D2 | b | z×Φd | f | H | H1 | Weight/kg |

| 50 | 250 | 165 | 125 | 99 | 20 | 4×Φ18 | 3 | 420 | 335 | 57 |

| 80 | 280 | 200 | 160 | 132 | 20 | 8×Φ18 | 3 | 615 | 510 | 75 |

| 100 | 300 | 220 | 180 | 156 | 22 | 8×Φ18 | 3 | 805 | 685 | 93 |

| 150 | 350 | 285 | 240 | 211 | 24 | 8×Φ22 | 3 | 652 | 790 | 155 |

| 200 | 400 | 340 | 295 | 266 | 24 | 8×Φ22 | 3 | 1085 | 885 | 217 |

| 250 | 450 | 395 | 350 | 319 | 26 | 12×Φ22 | 3 | 1235 | 1015 | 280 |

| 300 | 500 | 445 | 400 | 370 | 26 | 12×Φ22 | 4 | 1450 | 1190 | 350 |

| 350 | 550 | 525 | 460 | 429 | 26 | 16×Φ22 | 4 | 1640 | 1350 | 540 |

| 400 | 600 | 565 | 515 | 480 | 28 | 16×Φ26 | 4 | 1798 | 1460 | 820 |

| 450 | 650 | 615 | 565 | 530 | 28 | 20×Φ26 | 4 | 1980 | 1620 | 1120 |

| 500 | 700 | 670 | 620 | 582 | 30 | 20×Φ28 | 4 | 2190 | 1800 | 1440 |

PZ41H PN16 slag discharge gate valve

| DN | L | D | D1 | D2 | b | z×Φd | f | H | H1 | Weight/kg |

| 50 | 250 | 165 | 102 | 99 | 20 | 4×Φ18 | 3 | 420 | 335 | 60 |

| 80 | 280 | 200 | 133 | 132 | 22 | 8×Φ18 | 3 | 615 | 510 | 78 |

| 100 | 300 | 220 | 180 | 158 | 24 | 8×Φ18 | 3 | 805 | 685 | 96 |

| 150 | 350 | 285 | 240 | 212 | 28 | 8×Φ22 | 3 | 952 | 790 | 158 |

| 200 | 400 | 340 | 295 | 268 | 30 | 12×Φ22 | 3 | 1085 | 885 | 222 |

| 250 | 450 | 405 | 355 | 320 | 32 | 12×Φ26 | 3 | 1235 | 1015 | 289 |

| 300 | 500 | 460 | 410 | 370 | 34 | 12×Φ26 | 4 | 1450 | 1190 | 365 |

| 350 | 550 | 520 | 470 | 430 | 38 | 16×Φ26 | 4 | 1640 | 1350 | 558 |

| 400 | 600 | 580 | 525 | 482 | 40 | 16×Φ30 | 4 | 1798 | 1460 | 850 |

| 450 | 650 | 640 | 585 | 532 | 44 | 21×Φ30 | 4 | 1980 | 1620 | 1164 |

| 500 | 700 | 715 | 650 | 585 | 46 | 20×Φ33 | 4 | 2190 | 1800 | 1482 |

PZ41H PN25 slag discharge gate valve

| DN | L | D | D1 | D2 | b | z×Φd | f | H | H1 | Weight/kg |

| 50 | 250 | 165 | 125 | 102 | 20 | 4×Φ18 | 3 | 420 | 335 | 99 |

| 80 | 280 | 200 | 160 | 133 | 22 | 8×Φ18 | 3 | 615 | 510 | 118 |

| 100 | 300 | 235 | 190 | 158 | 24 | 8×Φ22 | 3 | 805 | 685 | 147 |

| 150 | 350 | 300 | 250 | 212 | 30 | 8×Φ26 | 3 | 952 | 790 | 204 |

| 200 | 400 | 360 | 310 | 278 | 34 | 12×Φ26 | 3 | 1085 | 885 | 273 |

| 250 | 450 | 425 | 370 | 335 | 36 | 12×Φ30 | 3 | 1235 | 1015 | 383 |

| 300 | 500 | 485 | 430 | 390 | 40 | 16×Φ30 | 4 | 1450 | 1190 | 478 |

| 350 | 550 | 555 | 490 | 450 | 44 | 16×Φ33 | 4 | 1640 | 1350 | 680 |

| 400 | 600 | 620 | 550 | 505 | 48 | 16×Φ36 | 4 | 1798 | 1460 | 1008 |

| 450 | 650 | 670 | 600 | 555 | 50 | 20×Φ36 | 4 | 1980 | 1620 | 1344 |

| 500 | 700 | 730 | 660 | 615 | 52 | 20×Φ36 | 4 | 2190 | 1800 | 1827 |

PZ41H PN40 slag discharge gate valve

| DN | L | D | D1 | D2 | b | z×Φd | f | H | H1 | Weight/kg |

| 50 | 250 | 165 | 125 | 88 | 20 | 4×Φ18 | 3 | 444 | 340 | 98 |

| 80 | 310 | 200 | 160 | 121 | 22 | 8×Φ18 | 3 | 636 | 508 | 126 |

| 100 | 350 | 235 | 190 | 150 | 24 | 8×Φ22 | 3.5 | 930 | 680 | 456 |

| 150 | 450 | 300 | 250 | 204 | 30 | 8×Φ26 | 3.5 | 984 | 800 | 228 |

| 200 | 550 | 375 | 320 | 260 | 38 | 12×Φ30 | 3.5 | 1094 | 875 | 298 |

| 250 | 650 | 450 | 382 | 313 | 42 | 12×Φ33 | 3.5 | 1270 | 1010 | 372 |

| 300 | 750 | 515 | 450 | 364 | 46 | 16×Φ33 | 3.5 | 1470 | 1180 | 450 |

| 350 | 850 | 580 | 510 | 422 | 52 | 16×Φ36 | 4 | 1555 | 1245 | 530 |

| 400 | 950 | 660 | 585 | 474 | 58 | 16×Φ39 | 4 | 1650 | 1280 | 610 |

| 450 | 4050 | 685 | 610 | 524 | 60 | 20×Φ39 | 4 | 1817 | 1415 | 690 |

| 500 | 1150 | 755 | 670 | 576 | 62 | 20×Φ42 | 4 | 1990 | 1560 | 772 |

PZ41H PN63 slag discharge gate valve

| DN | L | D | D1 | D2 | b | z×Φd | f | H | H1 | Weight/kg |

| 50 | 250 | 180 | 135 | 88 | 26 | 4×Φ22 | 3 | 444 | 340 | 142 |

| 80 | 310 | 215 | 170 | 121 | 30 | 8×Φ22 | 3 | 636 | 508 | 168 |

| 100 | 350 | 250 | 200 | 150 | 32 | 8×Φ26 | 3.5 | 830 | 680 | 210 |

| 150 | 450 | 345 | 280 | 204 | 38 | 8×Φ33 | 3.5 | 984 | 800 | 270 |

| 200 | 550 | 415 | 345 | 260 | 44 | 12×Φ36 | 3.5 | 1094 | 875 | 367 |

| 250 | 650 | 470 | 400 | 212 | 48 | 12×Φ36 | 3.5 | 1270 | 1010 | 450 |

| 300 | 750 | 530 | 460 | 364 | 54 | 16×Φ36 | 3.5 | 1470 | 1180 | 548 |

| 350 | 850 | 600 | 525 | 422 | 60 | 16×Φ39 | 4 | 1555 | - | 532 |

| 400 | 950 | 670 | 585 | 474 | 66 | 16×Φ42 | 4 | 1650 | 1280 | 615 |

| 450 | 1050 | 715 | 630 | 524 | 70 | 20×Φ42 | 4 | 1817 | 1415 | 695 |

| 500 | 1150 | 800 | 705 | 476 | 76 | 20×Φ48 | 4 | 1990 | 1560 | 778 |

Previous :

WZ41H corrugated pipe gate valvenext :

Grooved rising stem gate valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported