This series of proportional pressure reducing valves is a regulating valve that proportionally reduces the pressure of the medium flowing through it. It utilizes the pressure generated by the different cross-sectional areas of the piston at both ends inside the valve body to change the pressure behind the valve and achieve the purpose of reducing pressure. Stable operation, capable of reducing both dynamic pressure and static pressure, with precise pressure reduction ratio. The valve has a simple structure, high-quality material selection, low price, and reliable performance. The reference ratios include 2:1, 3:1, 4:1, 3:2, 5:2, etc.

Item NO.:

XUVAL88-257Lead Time:

50 DaysProduct Orgin:

CHINAShipping Port:

ShanghaiPayment:

100%TTMain technical parameters

| Nominal pressure (MPa) | 1.6 | 2.5 | 4.0 | 6.4 | |

| Test pressure (MPa) | Housing | 2.4 | 3.75 | 6.0 | 9.6 |

| Seal | 1.76 | 2.75 | 4.4 | 7.04 | |

| Inlet pressure | ≤1.6 | ≤2.5 | ≤4.0 | ≤6.4 | |

| Pressure | 0.05~1.1 | 0.1~1.6 | 0.1~2.5 | 0.5~3.5 | |

| Applicable temperature (℃) | ≤250 | ≤350 | ≤400 | ≤425 | |

| Applicable Medium | Steam | ||||

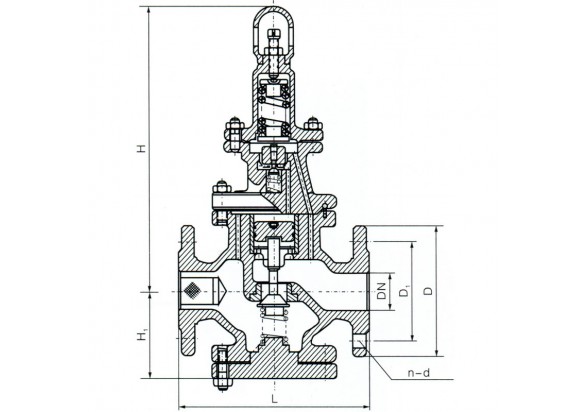

Main appearance and connection dimensions

| DN | L | H | H1 | 1.6MPa | 2.5MPa | 4.0MPa | 6.4MPa | ||||||||

| D | D1 | n-d | D | D1 | n-d | D | D1 | n-d | D | D1 | n-d | ||||

| 15 | 160/160 | 280 | 85 | 95 | 65 | 4-14 | 95 | 65 | 4-14 | 95 | 65 | 4-14 | 105 | 75 | 4-14 |

| 20 | 160/180 | 295 | 85 | 105 | 75 | 4-14 | 105 | 75 | 4-14 | 105 | 75 | 4-14 | 125 | 90 | 4-18 |

| 25 | 180/200 | 295 | 100 | 115 | 85 | 4-14 | 115 | 85 | 4-14 | 115 | 85 | 4-14 | 135 | 100 | 4-18 |

| 32 | 200/220 | 295 | 100 | 135 | 100 | 4-18 | 135 | 100 | 4-18 | 135 | 100 | 4-18 | 150 | 110 | 4-23 |

| 40 | 220/240 | 310 | 105 | 145 | 110 | 4-18 | 145 | 110 | 4-18 | 145 | 110 | 4-18 | 165 | 125 | 4-23 |

| 50 | 250/270 | 310 | 105 | 160 | 125 | 4-18 | 160 | 125 | 4-18 | 160 | 125 | 4-18 | 175 | 135 | 4-23 |

| 65 | 280/300 | 310 | 105 | 180 | 145 | 8-18 | 180 | 145 | 8-18 | 180 | 145 | 8-18 | 200 | 160 | 8-23 |

| 80 | 310/330 | 355 | 160 | 195 | 160 | 8-18 | 195 | 160 | 8-18 | 195 | 160 | 8-18 | 210 | 170 | 8-23 |

| 100 | 350/380 | 355 | 160 | 215 | 180 | 8-18 | 230 | 190 | 8-18 | 230 | 190 | 8-18 | 250 | 200 | 8-25 |

| 125 | 400/450 | 390 | 200 | 245 | 210 | 8-18 | 270 | 220 | 8-25 | 270 | 220 | 8-25 | 295 | 240 | 8-30 |

| 150 | 450/500 | 390 | 200 | 280 | 240 | 8-23 | 300 | 250 | 8-25 | 300 | 250 | 8-25 | 340 | 280 | 8-34 |

| 200 | 500/550 | 440 | 260 | 335 | 295 | 12-23 | 360 | 310 | 12-25 | 360 | 320 | 12-30 | 405 | 345 | 12-34 |

| 250 | 650 | 490 | 280 | 405 | 355 | 12-25 | 425 | 370 | 12-25 | 425 | 285 | 12-34 | 470 | 400 | 12-41 |

| 300 | 800 | 545 | 320 | 480 | 410 | 12-25 | 485 | 430 | 12-25 | 485 | 450 | 16-34 | 530 | 460 | 16-41 |

| 350 | 900 | 590 | 355 | 520 | 470 | 16-25 | 550 | 490 | 16-25 | 550 | 510 | 16-34 | 585 | 525 | 16-41 |

| 400 | 1000 | 635 | 390 | 580 | 525 | 16-30 | 610 | 550 | 16-30 | 610 | 585 | 16-41 | 670 | 585 | 16-48 |

Material for main parts

| Part Name | Material |

| Valve body, upper cover, lower cover, cap cover | Ductile iron, cast steel |

| Main disc, main valve seat, guide valve disc, guide valve seat | Stainless steel |

| Spring | Chromium vanadium steel, silicon manganese steel |

| Piston | Copper alloy, stainless steel |

Previous :

Gas pressure reducing valve YK43X/Hnext :

Fire pressure reducing valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported