This series of proportional pressure reducing valves is a regulating valve that proportionally reduces the pressure of the medium flowing through it. It utilizes the pressure generated by the different cross-sectional areas of the piston at both ends inside the valve body to change the pressure behind the valve and achieve the purpose of reducing pressure. Stable operation, capable of reducing both dynamic pressure and static pressure, with precise pressure reduction ratio. The valve has a simple structure, high-quality material selection, low price, and reliable performance. The reference ratios include 2:1, 3:1, 4:1, 3:2, 5:2, etc.

Item NO.:

XUVAL33-179Lead Time:

45 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

5When there is no water available in the pipeline network behind the valve, the valve is closed and the pressure ratio before and after the valve is fixed; When the fire hydrant or nozzle is used for spraying water in the pipeline network behind the valve, the pressure in front of the valve is greater than the pressure behind the valve. The piston is pushed back to open the proportional pressure reducing valve, and the pressure in the pipeline network behind the valve decreases with the increase of flow (in line with the flow pressure characteristic curve) until it reaches the equilibrium position, and the piston stops moving. When the pipe network behind the valve stops using water, due to the increase in pressure at the back of the piston, the proportional pressure reducing valve piston loses its balance and moves forward, causing the proportional pressure reducing valve to close. The general choice of a proportional pressure reducing valve is to keep the design flow rate on the straight section of the flow pressure characteristic curve, so that the pressure behind the valve and the pressure before the valve are still proportional.

| Main technical parameters | |

| Nominal pressure | 1.0~1.6MPa |

| Applicable Medium | Water, gas |

| Temperature | ≤180℃ |

| Flange standard | GB/T17241.6、JB/T79.1 |

| Test standards | GB/T13927 |

| Connection form | Flange,FNPT |

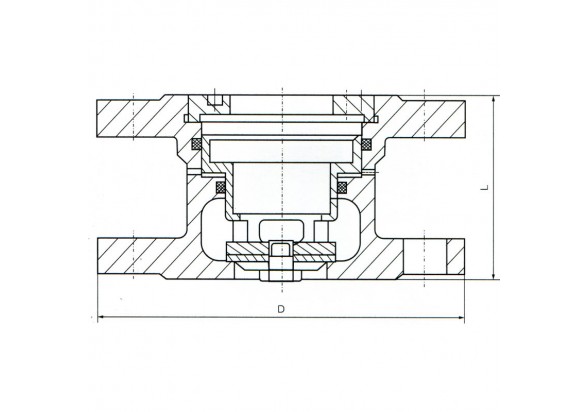

Main overall dimensions:

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| L | 78 | 85 | 102 | 122 | 140 | 160 | 178 | 230 |

| Material for main parts | ||||

| Body |

cast iron |

CI | copper alloy | stainless steel |

| Internal components | copper alloy | stainless steel | ||

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported