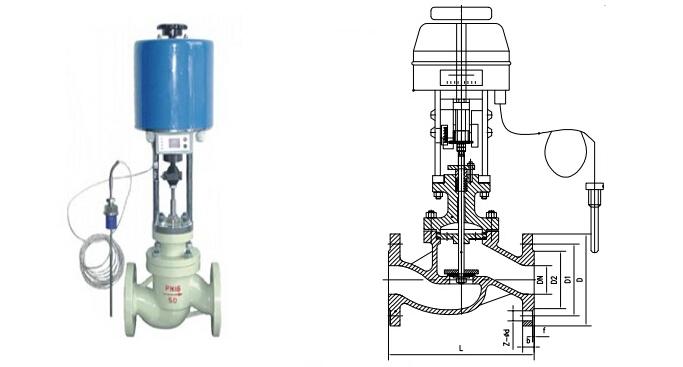

Product introduction: Self operated electric control temperature regulating valve (suitable for large diameter and heat transfer oil control). The biggest feature of the valve is that it only needs the common 220 V power supply, and uses the energy of the regulated medium to automatically adjust and control the temperature of steam, hot gas, hot oil and gas directly.

Item NO.:

XUVAL77-32Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

10ZZWPE temperature self operated [electronic] control valve

It can also be used in the occasion of preventing overheating or heat exchange. The valve has simple structure, convenient operation, wide range of temperature regulation and wide range of temperature control It is widely used in the hot water supply of chemical industry, petroleum, food, textile, hotels and restaurants.

Product features:

The nominal diameter of this series of products is from 20 to 200 mm, the nominal pressure is 1.0, 1.6, 4.0, 6.4 MPa, the temperature range is - 20 ℃ ~ 350 ℃, and the receiving signal is 0 ~ 10 mA.DC or 4 ~ 20 MA.DC to change the flow rate of the regulated medium, so as to keep the controlled process parameters at the given value. The single seat regulating type is suitable for the occasions with small pressure difference, large medium viscosity or slight particle impurities. The sleeve adjustment type is suitable for the occasions with large pressure difference.

Material of main parts:

Valve body and cover: HT200, ZG230-450, ZG1cr18NI9TI

Valve core: ZG1cr18NI9TI, Steller alloy surfacing reinforced polytetrafluoroethylene

Packing: PTFE, flexible graphite

Push rod and bushing: 2Cr13

Gasket: Rubber asbestos board, 10, 1Cr18Ni9Ti asbestos spiral wound gasket

Bellows: 1Cr18Ni9Ti

Technical parameter:

(Seat diameter DN)

20

25

32

40

50

65

80

100

125

150

200

(10)

(12)

(15)

(20)

Rated flow coefficient

Direct grade

1.8

2.8

4.4

6.9

11

17.6

27.5

44

69

110

176

275

440

690

Equal percentage

1.6

2.5

4

6.3

10

16

25

40

63

100

160

250

400

630

Rated stroke (mm)

16

25

40

60

Nominal pressure PN (MPA)

1.0 1.6 4.0 6.4

Inherent flow characteristics

Straight line, equal percentage

Inherent adjustable ratio

50

Allowable leakage

Single seat

Hard seal: Grade IV soft seal: grade VI

Sleeve

Hard seal: Grade II soft seal: grade VI

Working temperature T (℃)

-20~200 -40~250 -40~450 -60~450

Signal range (mA. DC)

0~10 4~20

Mode of action

Electrically closed and electrically open

Ambient temperature (℃)

Electric control valve: - 20 ~ 70 ℃

Humidity of working environment

Electric control valve: ≤ 95%

Supply voltage

220V 50Hz

ZAZ-60

DKZ-310

ZAZ-60

DKZ-310

DKZ-410

DKZ-510

400

4000

400

4000

640

16000

Nominal diameter DN (mm)

20

25

32

40

50

65

80

100

125

150

200

Electric actuator

Common type

DKZ-410

Electronic type

JHAZZ1

JHZAZ1

JHZAZ3

JHZAZ3

Common type

6400

Electronic type

2000

4000

6000

8000

Common type

12.5

20

32

48

Consumed power (N)

Electronic type

30

30

48

60

Common type

28

35

Electronic type

6

15

25

40

Allowable differential pressure

|

Nominal diameter

(mm)

Thrust (N)

|

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 | 125 | 150 | 200 | |||

| 10 | 12 | 15 | 20 |

|

|

|

|

|||||||

| 400 | 3.90 | 2.71 | 1.73 | 0.95 | 0.62 | 0.37 | 0.24 | 0.15 |

|

|

|

|

|

|

| 2000 | 6.40 | 6.40 | 6.40 | 4.84 | 3.11 |

|

|

|

|

|

|

|

|

|

| 4000 | 6.40 | 6.40 | 6.40 | 6.40 | 6.11 | 3.73 | 2.39 | 1.53 |

|

|

|

|

|

|

| 6000 |

|

|

|

|

|

|

|

|

1.38 | 0.91 | 0.54 |

|

|

|

| 6400 |

|

|

|

|

|

|

|

|

1.45 | 0.95 | 0.61 | 0.40 | 0.28 | 0.15 |

| 8000 |

|

|

|

|

|

|

|

|

|

|

|

0.50 | 0.34 | 0.19 |

| 16000 |

|

|

|

|

|

|

|

|

|

|

|

0.98 | 0.68 | 0.38 |

Allowable differential pressure gauge with sleeve adjustment

20

25

32

40

50

65

80

100

125

150

200

400

1.94

1.62

1.31

1.08

0.88

2000

6.40

6.40

4000

6.40

6.40

6.40

6.40

6.40

6000

6.40

6.40

6.40

6400

6.40

6.40

6.40

6.40

8000

6.40

6.40

6.40

16000

6.40

6.40

6.40

Main performance index

|

Serial number |

Project |

Single seat valve |

Sleeve valve |

| 1 |

Basic error (%) |

+-2.5 |

|

| 2 |

Return difference (%) |

2.0 | |

| 3 |

Dead zone (%)

|

3.0 | |

| 4 |

Rated stroke deviation (%) |

﹢-2.5 | |

| 5 |

Deviation of rated flow coefficient (%) |

﹢-10 | |

| 6 |

Inherent flow characteristics |

According to the slope deviation specified in IEC534-1 and GB/T4213-92 |

|

|

Nominal diameter DN |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| A |

460 |

530 |

630 | ||||||||

| B |

230 |

230 |

260 | ||||||||

| H1 | 490 | 540 | 625 | ||||||||

| L | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 |

| H2 | 175 | 180 | 215 | 218 | 230 | 280 | 285 |

|

400 | 460 | 540 |

| H3 | 53 | 57.5 | 70 | 75 | 82.5 | 92.5 | 100 | 110 | 125 | 142.5 | 170 |

|

Weight |

PN16/40 | 50 | 5254 | 56 | 58 | 75 | 87 | 95 | 132 | 135 | 155 |

| PN64 | 53 | 56 | 58 | 65 | 68 | 84 | 110 | 129 | 177 | 180 | |

Electronic unit: mm

|

Nominal diameter DN |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|

| D | 155 |

162 |

170 | |||||||||

| H4 | 290 | 325 | 380 | |||||||||

| L | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 |

|

| H5 | 175 | 180 | 215 | 218 | 230 | 280 | 285 | 315 | 400 | 460 | 540 |

|

| H6 | 53 | 58 | 70 | 75 | 82 | 92 | 100 | 110 | 125 | 142 | 170 |

|

| Weight | PN16/40 | 10 | 12 | 15 | 17 | 18 | 34 | 46 | 54 | 76 | 79 | 100 |

| pn64 | 13 | 16 | 19 | 26 | 27 | 43 | 69 | 85 | 120 | 125 | 150 | |

Connection size and standard:

Flange standard: cast iron flange according to GB4216-84, cast iron flange according to GB9113-88

Product structure chart

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

YG43H high sensitivity steam pressure reducing valvenext :

ZCD MINIATURE BRASS SOLENOID VALVEIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported