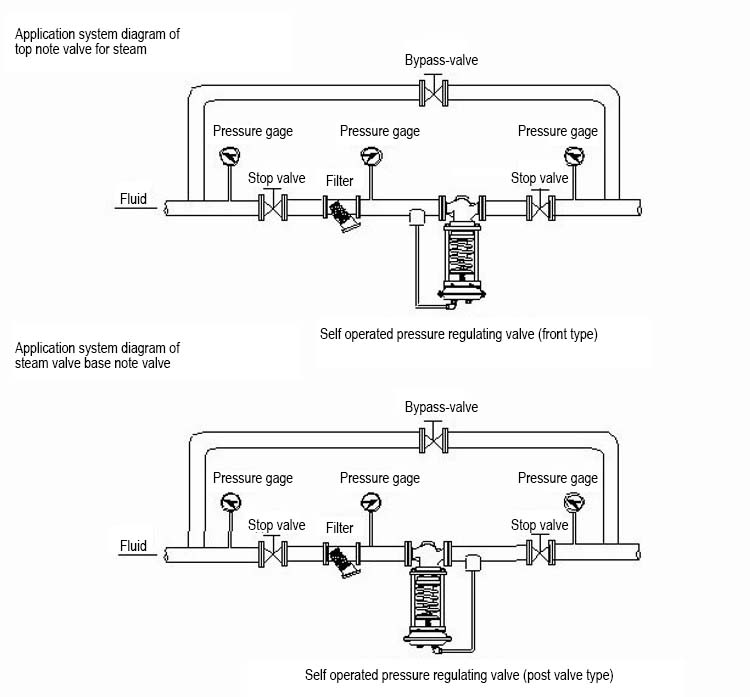

The self operated pressure regulating valve series products have three structures: single seat (ZZYP), sleeve (ZZYM), double (ZZYN), and so on; There are two types of actuators: membrane type and piston type; There are two types of functions: pressure regulation after the valve for pressure reduction (Type B) and pressure regulation before the valve for pressure relief Section (K-type). The nominal pressure ratings of products include PN16, 40, and 64; Valve body diameter range DN20~300; There are three levels of leakage: Level II, Level IV, and Level VI; The flow characteristic is fast opening; The pressure is adjusted in stages from 15 to 2500KPA. It can be combined as needed to meet the user's working conditions. The self operated pressure regulating valve does not require external energy, and uses the energy of the regulated medium as the power source to introduce the actuator to control the position of the valve core, changing the pressure difference and flow rate at both ends, and stabilizing the pressure before (or after) the valve. Self operated pressure regulating valves have the advantages of sensitive action, good sealing performance, and low pressure set point ripple force. Self operated pressure regulating valves are widely used for automatic control of gas, liquid, and medium pressure stabilization or pressure relief stabilization.

Item NO.:

XUVAL88-174Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1(1) The self operated pressure regulating valve does not require external energy and can work in places without electricity or gas, which is both convenient and energy-saving.

(2) The pressure segmentation range is fine and intersects with each other, with high adjustment accuracy.

(3) The pressure setting value can be continuously set during operation.

(4) The ratio of front valve pressure to rear valve pressure can be between 10:1 and 10:8 for regulating the pressure behind the valve.(5) Rubber diaphragm type detection, with high measurement accuracy and sensitive action of the actuator.

(6) Adopting a pressure balancing mechanism, the regulating valve responds sensitively and controls accurately.

Standard technical parameters

-Valve body

Form: Straight through single seat, double seat cast ball valve

Valve body size: DN20-300

Connection type: flange

Rated pressure: PN16, PN40, PN63

Flange standard: Steel flanges according to GB9113-2000, JBT-94

Sealing surface form: PN16 is convex, PN40/PN63 is concave convex

Flange end face distance: according to GB12221-89

Materials: ZG230-450 (SCPH2), ZG1Cr18NI9Ti (SCS13A)

ZG1Cr18Ni12Mo2Ti (SCS14A)

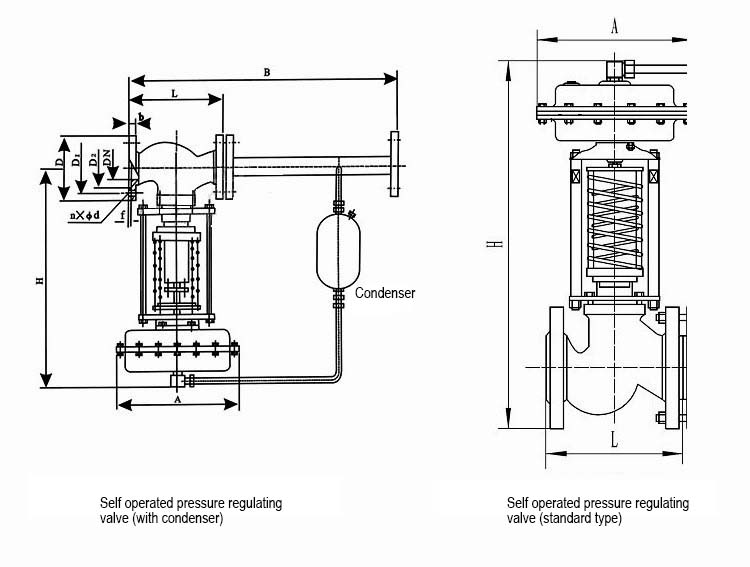

Structural form: standard type (-5 ℃~+80 ℃), medium temperature type (condenser) (<+350 ℃)

Bellows balanced type, piston balanced type

Gland type: threaded or pressure plate type

Filler: V-type polytetrafluoroethylene seasoning, flexible graphite filler

Gaskets: type, tooth shape, and flat shape

Material: F4, modified F4, stainless steel+graphite

-One valve internal component

Valve core: single seat plunger type valve core, pressure balance plunger type valve core, double seat plunger type valve core, metal seal, soft seal, quick opening characteristics

*Special requirements using equal percentage or linear characteristics

Materials: 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, PTFE

-Executive agency

Type: Thin film type (used for regulating pressure ≤ 0.6Mpa), ZY70, ZY100, ZY200, ZY280, ZY400

Diaphragm material: Nitrile rubber clip reinforced polyester fabric

Signal interface: internal thread M16x1.5

Environmental temperature: -30 ℃~+70 ℃

Type: piston type (used for adjusting pressure>0.6Mpa), ZY28, ZYH70, ZYH1.3,ZYH133, ZYH188, ZYH201

Piston material: ZALSi12

Signal interface: internal thread 16X1.5

Environmental temperature: -30 ℃~+70 ℃

-Attachment

Adjusting handle, other

-Performance

Rated Kv value: refer to Table 1

Flow characteristics: fast opening

Mode of action of the whole machine: pressure control before valve, pressure control after valve

Pressure regulation range: refer to Table 2

Pressure control accuracy: ± 8%

Valve seat leakage rate (for rated Kv value%):

Metal sealing less than 0.01% (ANSIB16.104-1976 Class IV)

Soft sealing less than 0.00001% (ANSIB16.104-1976 Class IV)

Paint color: The actuator of the regulating valve and the surface of the valve should be painted, while stainless steel and copper valves may not be painted

The user specified color on the valve body is also acceptable.

Table 1 Kv Value and Stroke

Table 2 Pressure Adjustment Range (Taking the Membrane actuator as an example,

1000-2500Kpa depends on specific operating conditions)

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported