Summary: KC8104Q pneumatic diaphragm sleeve control valve is a common improved product. In addition to the common sleeve valve has good stability, versatility, easy maintenance and other advantages; It also has the advantages of small volume, light weight and large flow coefficient.

Item NO.:

XUVAL77-36Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10KC8108Q pneumatic film insulation jacket single seat control valve

The single seal type is suitable for the medium with strict leakage requirement and small pressure difference. The double seal type is suitable for medium occasions with loose leakage requirements and large pressure difference.

KTJ5106Q pneumatic membrane insulation jacket single seat control valve is made of membrane single seat control valve and insulation jacket. When the crystallization temperature of the process medium is lower than the ambient temperature or the fluid temperature decreases, resulting in the increase of viscosity or the solidification of the fluid, the steam insulation jacket device is added at the valve body and valve cover, which is suitable for the occasions requiring heat preservation, and the medium meets the needs of process control.

C8104Q pneumatic diaphragm sleeve control valve is a common improved product. It has the advantages of good stability, strong versatility and easy maintenance; It also has the advantages of small volume, light weight and large flow coefficient. The single seal type is suitable for the medium with strict leakage requirement and small pressure difference. The double seal type is suitable for medium occasions with loose leakage requirements and large pressure difference.

Main performance index:

Leakage rate: hard seal grade IV, less than 10 "return difference of rated flow; without positioning seat, less than 3% of full stroke; Basic error: without positioner, less than + - 5% of full stroke; Deadband: without positioner, less than 3% of full stroke

Soft seal grade VI, less than 10 "of rated flow with positioner, less than 1% of full stroke with positioner, less than + - 1% of full stroke and less than 1% of full stroke.

Main technical performance index:

Leakage rate: less than 10-4% of valve rated capacity

Without positioner: less than 3% of full stroke

Return error: with positioning, less than 1% of the full stroke; without positioning, less than + - 5% of the full stroke

Basic error: with positioning, less than + - 3 of full stroke.

Main technical parameters:

|

Nominal diameter |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

|

Seat diameter |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

|

Rated Cv |

HLSB | 6.3 | 10 |

|

|

|

|

|

|

|

|

|

| HTSB |

|

|

|

24 | 44 | 68 | 99 | 175 | 275 | 360 |

|

|

| ZMPO | 5 | 8 | 13 | 22 | 32 | 50 | 80 | 120 | 200 | 280 | 450 | |

| ZJHPO | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 400 | 630 | |

|

Rated travel |

16 | 25 | 40 | 60 | ||||||||

|

Adjustable range |

50:1 | |||||||||||

|

Nominal pressure |

ANSI125、150、30;JIS10、16、20K;PN1.6、2.5、4.0MPa | |||||||||||

|

Valve core form |

Straight through single seat casting ball valve |

|||||||||||

|

Flow characteristics |

Equal percentage, straight line |

|||||||||||

|

Form of action |

Air to open and air to close |

|||||||||||

|

Working temperature |

Normal temperature type (P); 0~+250; Elongation type 1 (EI)+ 250~+560℃ |

|||||||||||

|

Flange standard |

JIS B2201-1984、ANSIB16.5-1981、JB/T9.2-94、HG20592-2009 |

|||||||||||

|

Actuator |

ZMBA; Pneumatic diaphragm actuator/ZHBA; Fine and small pneumatic diaphragm actuator |

|||||||||||

|

Accessories available |

Positioner, solenoid valve air filter pressure reducing valve, limit switch valve position feedback device, emergency action device hand wheel mechanism, etc |

|||||||||||

|

Part name |

Body |

Core seat packing |

Filler |

|

Texture of material |

ZG230-450 、ZG1Cr18Ni9Ti、316、316L、Corrosion resistant alloy, etc | 1Cr18Ni9Ti、1Cr18Ni12Mo2T、17-4PH、9Cr18、316L、Corrosion resistant alloy、F4,etc |

Graphite packing, polytetrafluoroethylene |

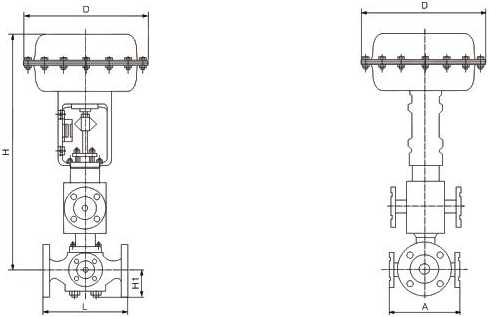

Outline and connection dimension:

PN1.6MPa

ANSI150RF

JIS10KRF

PN4.0MPa

ANSI150RF

JIS20KRF

PN1.6MPa

ANSI150RF

JIS10KRF

PN4.0MPa

ANSI150RF

JIS20KRF

Valve type

HLSO/HTSO

ZMPO/ZJHPO

L

A

H

D

L

A

H

D

Pressure rating/DN

Normal temperature type

Heat sink type

Normal temperature type

Heat sink type

20

184

197

180

490

640

285

181

194

180

398

548

285

25

184

197

180

490

640

285

184

197

180

410

560

32

222

235

220

435

585

40

340

370

220

500

665

285

222

235

220

455

605

50

400

400

260

595

765

285

254

267

260

457

607

360

65

430

440

300

630

810

360

276

292

300

610

790

80

460

470

360

640

820

360

298

317

360

622

807

100

510

540

400

890

1110

360

352

368

400

640

850

125

410

425

450

850

1110

470

150

600

660

500

955

1215

470

451

473

500

870

1130

200

600

600

680

890

1150

Jacket material:

Carbon steel, 1Cr18Ni9Ti

Steam pressure: ≤ 1.0MPa

Steam temperature: ≤ 350 ℃

Steam connection: DN 15 flange connection or G5 thread connection (GB3741.1-83).

Product structure chart:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

KC8112Q pneumatic diaphragm cage single seat control valvenext :

KTJ5101D electronic electric single seat regulating valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported