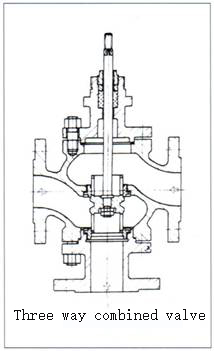

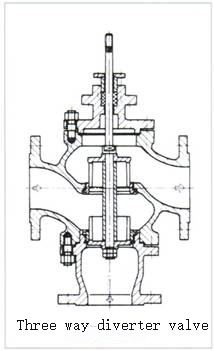

Overview of ZX pneumatic diaphragm three way control valve: ZX new series pneumatic diaphragm three-way control valve adopts cylindrical thin-wall window valve core guide,which is different from the bushing guide of plunger valve core.Equipped with multi spring actuator.ZX type pneumatic diaphragm control valve has the advantages of simple structure,light weight,small volume and convenient disassembly.Widely used in accurate control of gas,liquid and other media,process parameters such as pressure,flow,temperature,liquid level to maintain a given value.The utility model is suitable for the occasions where one fluid flows out in two paths through the three-way valve or two fluids are combined into one fluid through the three-way valve. This series of products have two kinds of three-way confluence (ZXQ) and three-way shunt (ZXX). The nominal pressure rating is 1.6, 4.0 and 6.4Mpa, and the diameter range of valve body is DN25-200. The applicable fluid temperature ranges from - 60℃ to + 450℃.The leakage standard is grade IV.There are two kinds of flow characteristics:straight line and parabola.

Item NO.:

XUVAL77-27Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

silveryMOQ:

10

Pneumatic diaphragm three-way on/off control valve

Overview of ZX pneumatic diaphragm three way control valve:

ZX new series pneumatic diaphragm three-way control valve adopts cylindrical thin-wall window valve core guide,which is different from the bushing guide of plunger valve core.Equipped with multi spring actuator.ZX type pneumatic diaphragm control valve has the advantages of simple structure,light weight,small volume and convenient disassembly.Widely used in accurate control of gas,liquid and other media,process parameters such as pressure,flow,temperature,liquid level to maintain a given value.The utility model is suitable for the occasions where one fluid flows out in two paths through the three-way valve or two fluids are combined into one fluid through the three-way valve.This series of products have two kinds of three-way confluence (ZXQ) and three-way shunt (ZXX). The nominal pressure rating is 1.6, 4.0 and 6.4Mpa, and the diameter range of valve body is DN25-200. The applicable fluid temperature ranges from - 60℃ to + 450℃.The leakage standard is grade IV.There are two kinds of flow characteristics:straight line and parabola.

Characteristics of ZX pneumatic diaphragm three way control valve:

The flow direction of the fluid acting on the valve core is in the open state,so the valve can work stably.

In addition to the guide of the bushing at the upper valve cover,the side of the valve core and the inner surface of the valve seat also have a guiding effect,with large guiding area and reliable operation.

The actuator adopts multi spring structure,which reduces the height by 30% and the weight by 30%.

Material of main parts of ZX pneumatic diaphragm three way control valve:

Valve body and cover:HT200,ZG230-450,ZG1Cr18Ni9Ti

Valve core and seat:1Cr18Ni9Ti

Corrugated diaphragm:NBR clip reinforced polyester fabric

Packing: PTFE,flexible graphite

Spring:60Si2Mn

Membrane cover:A3

Push rod and stem:2Cr13,1Cr18Ni9Ti

Bushing:2Cr13

Gasket:Rubber asbestos board,10,1Cr18Ni9Ti,asbestos spiral wound gasket

Specifications and technical parameters of ZX pneumatic diaphragm three way control valve:

| Nominal diameter DN(mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Rated flow coefficient Kv | Confluence | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 |

| Shunt | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | |

| Rated travel L(mm) | 16 | 25 | 40 | 60 | |||||||

| Effective area of diaphragm Ae(cm2) | 280 | 400 | 600 | 1000 | |||||||

| Nominal pressure PN(MPa) | 1.6、4.0、6.4 | ||||||||||

| Inherent flow characteristics | Straight line, parabola | ||||||||||

| Inherent adjustable ratio R | 30 | ||||||||||

| Working temperaturet(℃) |

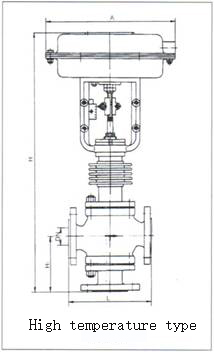

Common type:cast iron-20 ~ 200 cast steel-40 ~ 250 cast stainless steel-60 ~ 250 Heat dissipation type:cast steel-40 ~ 450,cast stainless steel-60 ~ 450 |

||||||||||

| Temperature difference between two media t(℃) | Cast iron ≤ 150,cast steel ≤ 200 | ||||||||||

| Signal range Pr(kPa) | 40~200 | ||||||||||

| Air pressure Ps(MPa) | 0.14~0.4 | ||||||||||

| Allowable leakage |

10-4 × valve rated capacity |

||||||||||

| Allowable pressure difference △ p(MPa) | 0.86 | 0.75 | 0.48 | 0.31 | 0.27 | 0.18 | 0.11 | 0.12 | 0.09 | 0.05 | |

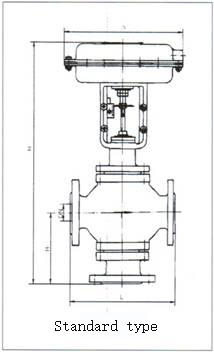

Dimensions and weight of ZX pneumatic diaphragm three way control valve (unit: mm)

| Nominal diameter | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||

| A | 282 | 306 | 306 | 306 | 394 | 394 | 394 | 498 | 498 | 498 | ||

| H1 | PN16 | 121 | 130 | 140 | 153 | 178 | 190 | 200 | 260 | 320 | 360 | |

| PN40 | 130 | 140 | 150 | 160 | 185 | 200 | 220 | 280 | 320 | 380 | ||

| PN64 | 160 | 170 | 180 | 200 | 230 | 250 | 282 | 310 | 430 | 480 | ||

| H | Common type | PN16 PN40 | 490 | 480 | 540 | 580 | 710 | 730 | 750 | 895 | 1005 | 1045 |

| PN64 | 560 | 561 | 596 | 630 | 760 | 798 | 876 | 892 | 1200 | 1263 | ||

| High temperature type | 600 | 615 | 650 | 670 | 850 | 870 | 900 | 1040 | 1330 | 1370 | ||

|

heavy amount (kg) |

Common type | PN16 PN40 | 21 | 23 | 33 | 36 | 64 | 72 | 92 | 155 | 193 | 286 |

| PN64 | 25 | 28 | 40 | 45 | 74 | 85 | 112 | 180 | 243 | 336 | ||

| High temperature type | Weight gain (5-10)% | |||||||||||

Note: 1.The height and weight of high temperature type in this table are based on PN16.

2.The height of the mechanism with hand wheel should be increased by 152 (DN20-50),182 (DN65-100),253 (DN 125-200)

Connection dimension and standard of ZX pneumatic diaphragm three way control valve:

Flange standard:cast iron flange according to GB4216.5-84

Cast steel flange according to GB9113-88,JB/T79.1-94

Flange sealing surface type:PN10,PN16 are convex surface

PN40 and pn64 are concave and convex,and the valve body is concave.

Structure length:according to the standard of GB12221-89

Diaphragm actuator gas signal interface: internal thread M16 × 1.5

Jacket thermal insulation jacket heat carrier interface:butt welding φ 18 × 4

the valve body flange and flange end face distance can be manufactured according to the user specified standard.Such as:ANSI,JIS,DIN and other standards.

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

ZFQ-1 all weather explosion-proof fire resistant breathing valvenext :

V230 self operated pressure regulating valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported