Introduction: ZFQ-1 explosion-proof fire-proof breathing valve produced by our company is a relatively new product in China. It is a new product with flame arrester and breathing valve. Its new structure is the first in China. It is a necessary safety equipment for petrochemical storage tank. Its biggest advantages are good fire resistance, stable suction performance, simple structure, light weight and convenient maintenance. The product is suitable for storage of class a oil with flash point lower than 28 ℃ and class B oil with flash point lower than 60 ℃, such as gasoline, kerosene, diesel oil, crude oil, toluene, ethanol, aromatics, sulfur and other media tanks. It works normally in the temperature environment of -35 ℃ -60 ℃.

Item NO.:

XUVAL77-29Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

blueMOQ:

106. The fire resisting layer is easy to repair, clean and install. It is unnecessary to dismantle the breathing valve during inspection.

Performance:

1. The low temperature resistance and antifreeze performance are qualified, and the pressure disc, vacuum valve disc and sealing ring are free of deformation after operating at - 42 ℃ for 2 hours, which fully meets the design requirements.

2. It can be operated continuously for 72 hours at 36 ℃ for 10000 times. The contact surfaces of pressure valve disc, vacuum valve disc and guide rod have no signs of wear and bruise, and the guide rod is sensitive to rise and fall without jamming.

3. The results show that the explosion resistance is qualified, and the fire resistance is successful in 13 consecutive explosion resistance tests.

4. The fire resistance is qualified.

Specification and dimension table:

Specifications

Installation dimension

D

D1

L

H

H1

n-Ø

DN50

Ø140

Ø110

Ø170

299

157

4-Ø14

DN80

Ø185

Ø150

Ø235

340

178

4-Ø18

DN100

Ø205

Ø170

Ø265

376

185

4-Ø18

DN150

Ø260

Ø225

Ø240

457

210

8-Ø18

DN200

Ø315

Ø280

Ø280

600

243

8-Ø18

DN250

Ø370

Ø335

Ø450

690

283

12-Ø18

Note: the connecting flange meets the requirements of jb78-59 "cast iron flange".

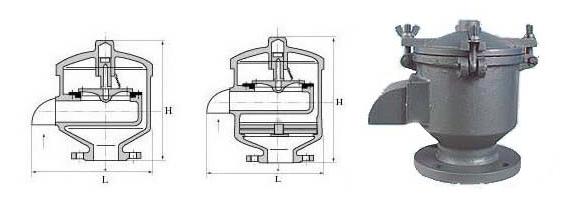

Product structure chart:

Maintenance and repair:

In order to ensure that the performance of the new all-weather explosion-proof breathing valve can be fully used, the breathing valve and fire resistance layer should be inspected within half a year.

1. Check whether the action of pressure valve disc and vacuum valve disc is sensitive, and whether the contact surface of guide rod and valve seal ring is damaged.

2. When re installing the pressure valve disc, make sure that the contact surface is tight and the guide rod rises and falls sensitively.

3. When a new breathing valve is used, the shockproof material of the valve disc must be removed.

4. Check whether the core of fire retardant layer is blocked, deformed, corroded, etc.

5. Check that the blocked fire retardant layer core should be cleaned to ensure that each hole on the core is unblocked, and the deformed and corroded fire retardant layer should be replaced in time.

6. When re installing the core of fire retardant layer, it should be ensured that the combination is tight without air leakage.

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

ZZYP-16B self operated pressure regulating valvenext :

Pneumatic diaphragm three-way on/off control valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported