Summary: The direct acting self operated pressure (differential pressure) regulating valve (V230 self operated pressure regulating valve) is composed of valve body,valve seat,valve core and other parts.It is an energy-saving product that can automatically adjust the pressure only by the pressure change of the regulated medium without external energy.It can be used for pressure control of non corrosive (maximum temperature 350 ℃) liquid,gas,steam and other media It is widely used in petroleum,chemical industry,metallurgy,light industry and other industrial sectors as well as urban heating and heating system.

Item NO.:

XUVAL77-26Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

silveryMOQ:

10V230 self operated pressure regulating valve

Summary:

The direct acting self operated pressure (differential pressure) regulating valve (V230 self operated pressure regulating valve) is composed of valve body,valve seat,valve core and other parts.It is an energy-saving product that can automatically adjust the pressure only by the pressure change of the regulated medium without external energy.It can be used for pressure control of non corrosive (maximum temperature 350 ℃) liquid,gas,steam and other media It is widely used in petroleum,chemical industry,metallurgy,light industry and other industrial sectors as well as urban heating and heating system.

Model and specification:

| Category | Pressure control regulating valve | Differential pressure control valve | ||||||

| Pressure regulating valve behind valve | Pre valve pressure regulating valve | Differential pressure rise valve closed | Differential pressure rising valve open | |||||

| Hard seal | Soft seal | Hard seal | Soft seal | Hard seal | Soft seal | Hard seal | Soft seal | |

| Model | V230D01 | V230D01 | V230D02 | V230D02 | V230D03 | V230D03 | V230D04 | V230D04 |

| Specifications | DN15-250 | |||||||

Main technical parameters of control valve:

| Nominal diameter(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| Rated flow coefficient(Kvs) | 3.2 | 5 | 8 | 12.5 | 20 | 32 | 50 | 80 | 125 | 160 | 320 | 450 | 630 | |

| Nominal pressure(Mpa) | 1.6; 4.0 | |||||||||||||

| Z value | 0.6 | 0.6 | 0.6 | 0.55 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 | 0.35 | 0.3 | 0.2 | 0.2 | |

|

Highest work temperature ℃ |

V230 V231 |

Liquid ≤ 140;gas ≤ 80 | ||||||||||||

|

Hard seal V230 |

With isolation tank≤ 200 |

With isolation tank and Extension ≤ 300 |

||||||||||||

| With isolation tank and radiator≤ 200 | ||||||||||||||

| Pressure balance element | corrugated pipe | Rolling diaphragm | ||||||||||||

| Flange standard | DIA(flange standard can also be provided according to user's requirement) | |||||||||||||

| Body material | PN16:cast iron (working temperature ≤ 200 ℃)PN40:cast steel,cast stainless steel(working temperature ≤ 350 ℃) | |||||||||||||

| Material of valve core | Stainless steel:the soft seal is stainless steel inlaid with rubber ring | |||||||||||||

| Maximum working pressure(MPa) | Nominal pressure(pay attention to the relationship between △ Pmax and working pressure and working temperature) | |||||||||||||

Note:

1.When liquid temperature is higher than 140 ℃ and gas temperature is higher than 80 ℃,the valve is inverted;

2.Z value:noise measurement system.This value is used to measure the noise level.

Main technical parameters of actuator

| Model | V230 D01(D03) V231D01(D03) | V230 D02(D04) V231D02(D04) | ||||||

| Effective area(㎝2) | 23※ | 80※ | 250 | 630 | 23※ |

80※ |

250 |

630 |

| Pressure setting range(MPa) | 0.3~1.2 | 0.1~0.6 | 0.015~0.15 | 0.005~0.035 | 0.3~1.1 | 0.1~0.5 | 0.015~0.12 | 0.005~0.035 |

| 0.8~1.6 | 0.05~0.3 | 0.01~0.07 | 1.0~1.6 | 0.05~0.25 | 0.01~0.06 | |||

|

Ensure the pressure valve is working normally Minimum pressure difference P MPa |

≥0.05 | ≥0.04 | ≥0.01 | ≥0.005 | ≥0.05 | ≥0.04 | ≥0.01 | ≥0.05 |

|

Between the upper and lower membrane chambers is allowed Maximum pressure difference MPa |

2.0 | 1.25 | 0.4 | 0.15 | 2.0 | 1.25 | 0.4 | 0.15 |

| Trip(mm) | 18 | 18 | 23 | 23 | 18 | 18 | 23 | 23 |

| Texture of material | Diaphragm:EPDM or FKM clip fiber;diaphragm cover:galvanized steel plate | |||||||

| Control pipeline and joint | Copper pipe or steel pipe 10 × 1;ferrule type joint R quarter ″ | |||||||

Performance index:

| Control accuracy | ±8% | |||

|

Allowable leakage (under specified test conditions) l/h |

Hard seal | Rated capacity of 4 × 10-4 valve | ||

| Soft seal | DN15~50 | DN65~125 | DN150~250 | |

| 10 bubbles/min | 20 bubbles/min | 40 bubbles/min | ||

Allowable differential pressure:

| Nominal diameter(mm) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

| PN16 maximum differential pressure △ P MPa | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.5 | 1.5 | 1.2 | 1.0 | 1.0 |

| PN40 maximum pressure difference △ P MPa | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 1.5 | 1.5 | 1.2 | 1.0 | 1.0 |

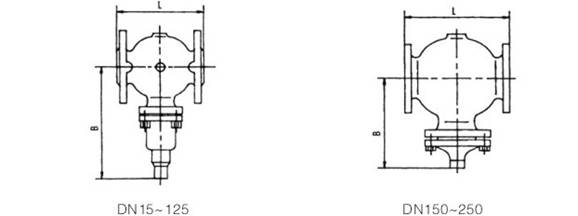

Dimensions:

Size and weight of V230 / v231 control valve:

| Nominal diameter(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

| L mm | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 |

| B mm | 212 | 238 | 238 | 240 | 240 | 275 | 275 | 380 | 380 | 295 | 325 | 372 |

| Approximate weight(kg) | 6.7 | 9.7 | 13 | 14 | 17 | 29 | 33 | 60 | 70 | 80 | 140 | 220 |

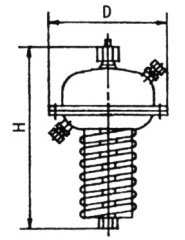

Dimension and weight of D02(D04) actuator:

| Effective area cm2 | 32 | 80 | 250 | 630 |

| D mm | 172 | 172 | 263 | 380 |

| H mm | 435 | 430 | 470 | 520 |

| Approximate weight kg | 7.5 | 7.5 | 13 | 28 |

Size and weight of D01(D03) actuator:

| Effective area cm2 | 32 | 80 | 250 | 630 |

| D mm | 172 | 172 | 263 | 380 |

| H mm | 440 | 435 | 440 | 520 |

| Approximate weight kg | 7.5 | 7.5 | 13 |

28 |

Temperature range of main parts:

| Material | Temperature range (℃) |

| HT200 | -20~200 |

| QT400-18 QT400-15 | -20~350 |

| ZG230-450 | -40~450 |

| ZG1Cr18Ni9Ti ZG0Cr18Ni12Mo2Ti | -250~550 |

| 2Cr13 | -20~450 |

| 1Cr18Ni9 | -196~550 |

| 0Cr18Ni12Mo2Ti | -196~600 |

| Teflon | -40~200 |

| Carbon fibre | -120~350 |

| Flexible graphite | -200~600 |

| 5860 plastic clip 480d551 cotton canvas | -40~80 |

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Pneumatic diaphragm three-way on/off control valvenext :

Stainless steel explosion proof small flow regulating valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported