Overview of BZ41H insulated gate valve: The insulated gate valve is mainly used in petroleum, chemical, metallurgical, pharmaceutical and other systems. The jacket of the valve is welded between the two flanges of the valve. The side and bottom of the valve are equipped with the connection port of the jacket. The jacket can freely flow through steam or other thermal insulation medium to ensure that the viscous medium can flow through the valve smoothly.

Item NO.:

XUVAL77-52Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10BZ41H insulated gate valve

Brief introduction of insulation valve structure:

The heat preservation valve is welded with a layer of metal jacket in the valve body. By injecting steam, heat transfer oil, cooling water and air conditioner into the metal jacket, the medium of the valve body can reach the required temperature under normal temperature, heating and cooling conditions, so as to play the role of heat preservation or cold preservation. Insulation valve is used in the room temperature will solidify high viscosity, steam or other insulation, insulation medium, to ensure that the valve medium can work normally.

The principle of heat preservation valve:

The valve has good heat preservation and cold preservation characteristics, and the valve diameter is consistent with the pipe diameter, and can effectively reduce the heat loss of medium in the pipeline. It has good heat preservation and cold keeping property, and can effectively reduce the heat loss of medium in the pipeline. The heat preservation valve has been widely used in petroleum, chemical, metallurgy, pharmaceutical and other systems, which can effectively reduce the loss of medium heat in the pipeline and prevent the appearance of the similar phenomena such as medium crystallization and solidification. The function of the heat preservation valve is to pass through the valve under the condition of high or low temperature, the material in the insulation valve will have the insulation effect on the medium, so that the medium will not condense or stick to the valve body, so that the valve can be opened and closed to operate normally.

Classification of insulation valves:

The products conform to GB, DIN, ANSI and other international standards. Insulation valve is also divided into: insulation ball valve, insulation gate valve, insulation butterfly valve, insulation discharge valve, insulation stop valve, Insulation check valve, insulation filter. Insulation valve, etc. The products are widely used, suitable for large and small caliber, complete variety.

Insulation valve standard:

Gate valve: design and manufacture [GB12234]

Plug valve: design and manufacture standard [GB/T 22130]

Globe valve: design and manufacture standard [GB/T 12234]

Ball valve: design and manufacture standard [GB/T12224, ASME B 16.34]

Executive standard for BZ41H insulated gate valve:

Design and manufacture: GB12234

Flange size: JB/T79 GB9113

Pressure and temperature: GB9131

Structure length: GB12221

Butt welding connection size: --

Inspection and test: GB 13927

Material of main parts of insulated gate valve:

Material of parts

Material

BZ41Y-16I-25I-40I

BA41Y-16I-25I-40I

BZ41Y-16I-25I-40I

Body and valve fabrication

Chromium molybdenum steel

Disc

Alloy steel + cemented carbide

Chromium nickel titanium steel

Cr Ni Mo Ti steel

Stem

Alloy steel

Stem nut

Aluminum iron bronze

Handwheel

Grey cast iron, malleable cast iron

Performance specification:

BZ41H-16C

BZ41W-16P(R)

Model

Nominal pressure

Strength (water) (MPa)

Seal (water) (MPa)

Low pressure seal (air) (MPa)

Working temperature ℃

Applicable medium

1.6

2.4

1.8

0.6

≤200

Acids and bases

BZ41W-25P(R)

2.5

3.8

2.8

0.6

≤200

Acids and bases

BZ41W-40P(R)

4.0

6.0

4.4

0.6

≤200

Acids and bases

BZ41W-64P(R)

6.4

9.6

7.0

0.6

≤200

Acids and bases

External dimension and connection dimension:

Model

Nominal diameter DN

Size

BZ41W-16P(R)

L

D

D1

D2

b-f

Z-∅d

H

DO

15

130

95

65

45

16-2

4-14

170

120

20

150

105

75

55

16-2

4-14

190

140

25

160

115

85

65

16-2

4-14

205

160

32

180

135

100

78

18-2

4-18

270

180

40

200

145

110

85

18-3

4-18

310

200

50

250

160

125

100

18-3

4-18

358

240

65

265

180

145

120

18-3

4-18

373

240

80

280

195

160

135

20-3

8-18

435

280

100

300

215

180

155

20-3

8-18

500

300

125

325

245

210

185

22-3

8-18

614

320

150

350

280

240

210

24-3

8-23

674

360

200

400

335

295

265

26-3

12-23

818

400

250

450

405

355

320

30-3

12-25

969

450

300

500

460

410

375

30-4

12-25

1145

560

Model

Nominal diameter DN

Size

BZ41W-40P(R)

L

D

D1

D2

D6

b-f

Z-∅d

H

15

130

95

65

45

40

16-2

4-14

135

20

150

105

75

55

51

16-2

4-14

190

25

160

115

85

65

58

16-2

4-14

205

32

180

135

100

78

66

18-2

4-18

270

40

200

145

110

85

76

18-3

4-18

310

50

250

160

125

100

88

20-3

4-18

371

65

280

180

145

120

110

22-3

8-18

39

80

310

195

160

135

121

22-3

8-18

455

100

350

230

190

160

150

24-3

8-23

551

125

400

270

220

188

176

28-3

8-25

628

150

450

300

250

218

204

30-3

8-25

708

200

550

375

320

282

260

38-3

12-30

885

250

650

445

385

345

313

42-3

12-24

960

Model

Nominal diameter DN

Size

L

D

D1

D2

D6

b-f

Z-∅d

H

BZ41W-64P(R)

15

130

105

75

55

41

18-2

4-14

140

20

150

125

90

68

51

20-2

4-18

195

25

160

135

100

78

58

22-2

4-18

210

32

180

150

110

82

66

24-2

4-23

280

40

200

165

125

95

76

24-3

4-23

328

50

250

175

135

105

88

26-3

4-23

390

65

280

200

160

130

110

28-3

8-23

410

80

310

210

170

140

121

30-3

8-23

485

100

350

250

200

168

150

32-3

8-25

590

125

400

295

240

202

176

36-3

8-30

688

150

450

340

280

240

204

38-3

8-34

768

200

550

405

345

300

260

44-3

12-34

972

250

650

470

400

350

313

48-3

12-41

1059

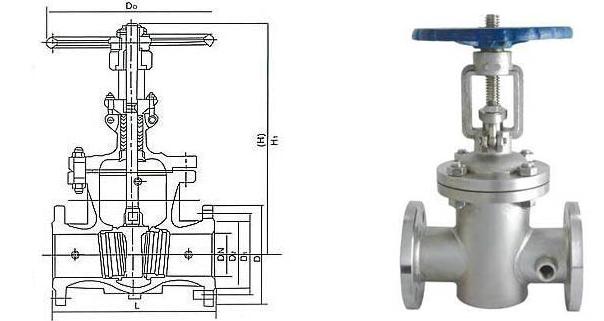

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported