Product use: SD34lX flange type telescopic butterfly valve has the function of automatically compensating the thermal expansion and cold contraction of the pipeline, which is convenient for loading and unloading. It is used as the best device to adjust the flow and load and cut off the fluid in the industrial pipelines with the temperature below 425 ℃ and the nominal pressure below 1.6Mpa, such as petroleum, chemical, electric power, papermaking, water supply and drainage, municipal construction, etc.

Item NO.:

XUVAL77-18Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

blueMOQ:

10

SD341X/F/H SD641X/F/H SD941X/F/H telescopic butterfly valve

Product use:

SD34lX flange type telescopic butterfly valve has the function of automatically compensating the thermal expansion and cold contraction of the pipeline, which is convenient for loading and unloading. It is used as the best device to adjust the flow and load and cut off the fluid in the industrial pipelines with the temperature below 425 ℃ and the nominal pressure below 1.6Mpa, such as petroleum, chemical, electric power, papermaking, water supply and drainage, municipal construction, etc.

Valve model:

The common models of flange type telescopic butterfly valve are: SD341X, SD341X-6, SD341X-10, SD341X-16, SD641X, SD641X-10P, SD941X, SD341F, SDS641F, SD341H, SD641H, SD941H, etc.

Product features:

1. Unique structure, flexible design, light weight, labor saving, quick opening and closing.

2. The telescopic butterfly valve can not only compensate the thermal expansion and cold contraction caused by the temperature difference shrinkage of the pipeline, but also provide convenience for the installation and replacement of the maintenance valve.

3. The sealing part can be adjusted and replaced, and the sealing performance is reliable.

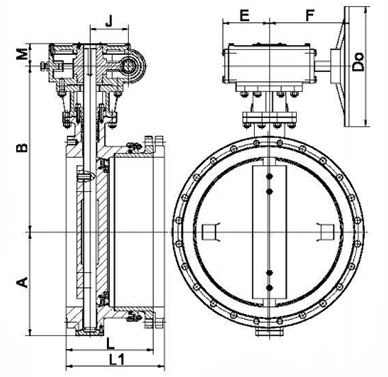

Structure diagram:

Installation precautions:

Before installation, the telescopic butterfly valve must be placed flat, do not bump at will, and do not remove the support during operation.

When the telescopic butterfly valve leaves the factory, the structure length is the minimum length. When it is installed, it is pulled to the installation length (i.e. the design length).

When the length between pipes exceeds the installation length of expansion valve, please adjust the pipe spacing. Do not stretch and shrink the butterfly valve forcibly to avoid damaging the butterfly valve.

The telescopic butterfly valve can be installed at any time. When it is used for temperature compensation, after the pipeline is installed, supports should be added at both ends along the pipeline axis to prevent the telescopic pipe of the telescopic valve from pulling out.

Performance parameters:

| Working pressure(MPa) | 0.6 | 1.0 | |||

| Applicable temperature(℃) | ≤120 | It depends on different gum types | ≤120 | ||

| Applicable medium | Water, sewage, oil, air, etc | It depends on different gum types | Water, sewage, oil, air, etc | ||

| Material | Valve body | Grey cast iron | Grey cast iron | Ductile iron | |

| Disc | Ductile iron (surface treatment) | Ductile iron, stainless steel | Ductile iron | ||

| Stem | 2Cr13 | Stainless steel, carbon steel | Chromium stainless steel | ||

Main dimensions:

| DN | L | L1 max | A | B | E | F | J | M | Do |

| 50 | 160 | 172 | 83 | 120 | 90 | 205 | 83 | 115 | 200 |

| 65 | 160 | 172 | 89 | 145 | 90 | 205 | 83 | 115 | 200 |

| 80 | 180 | 195 | 98 | 158 | 90 | 205 | 83 | 115 | 200 |

| 100 | 195 | 215 | 110 | 170 | 90 | 205 | 83 | 115 | 200 |

| 125 | 205 | 225 | 123 | 182 | 90 | 205 | 83 | 115 | 200 |

| 150 | 205 | 225 | 140 | 210 | 90 | 205 | 83 | 115 | 200 |

| 200 | 218 | 238 | 170 | 238 | 90 | 205 | 83 | 115 | 200 |

| 250 | 233 | 258 | 195 | 270 | 90 | 205 | 83 | 134 | 250 |

| 300 | 248 | 268 | 222 | 300 | 90 | 205 | 83 | 134 | 250 |

| 350 | 278 | 303 | 252 | 330 | 120 | 265 | 141 | 159 | 250 |

| 400 | 298 | 323 | 285 | 368 | 120 | 265 | 141 | 159 | 250 |

| 450 | 311 | 336 | 310 | 402 | 185 | 250 | 115 | 163 | 250 |

| 500 | 330 | 355 | 337 | 438 | 185 | 250 | 115 | 163 | 315 |

| 600 | 350 | 375 | 393 | 490 | 245 | 400 | 145 | 185 | 315 |

| 700 | 364 | 395 | 450 | 558 | 245 | 400 | 145 | 185 | 315 |

| 800 | 415 | 445 | 515 | 625 | 310 | 460 | 191 | 220 | 315 |

| 900 | 435 | 475 | 560 | 685 | 310 | 460 | 191 | 220 | 400 |

| 1000 | 510 | 550 | 610 | 750 | 410 | 55 | 270 | 255 | 400 |

| 1200 | 590 | 630 | 825 | 880 | 410 | 55 | 270 | 255 | 400 |

| 1400 | 590 | 630 | 840 | 987 | 520 | 640 | 351 | 320 | 400 |

| 1600 | 626 | 660 | 960 | 1158 | 520 | 785 | 440 | 335 | 630 |

| 1800 | 670 | 710 | 1060 | 1258 | 520 | 640 | 351 | 320 | 400 |

| 2000 | 680 | 720 | 1165 | 1365 | 520 | 640 | 351 | 320 | 400 |

| 2200 | 700 | 740 | 1325 | 1470 | 520 | 640 | 351 | 320 | 400 |

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported