FEP(F46),PTFE(F4) Fluorine-lined butterfly valves are applicable for -50℃~150℃ nitrohydrochloric acid,sulfuric acid,hydrochloric acid,hydrifluoric acid of vanous concentrations and vanous organic acid, strongacid and strong oxidant.

Item NO.:

XU069Lead Time:

35DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

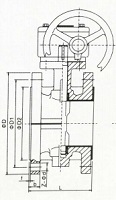

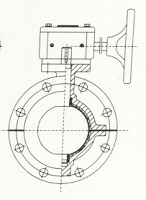

5D341F46 Fluorine lined rubber lined butterfly valve

FEP(F46),PTFE(F4) Fluorine-lined butterfly valves are applicable for -50℃~150℃ nitrohydrochloric acid,sulfuric acid,hydrochloric acid,hydrifluoric acid of vanous concentrations and vanous organic acid, strongacid and strong oxidant.

FEP is also applicable for the pipeline of strong alkali and organic solvent of various concentrations as well as other corrosive air and liquid media.

Drive way: Worm wheel,manual,electric,pneumatic.

|

MajorPartsMaterial |

|||||||

| No. | Part name | Cast iron |

Cast steel |

Stainless steel |

Ultra-low carbon stainless steel |

||

|

Z |

C |

P | V |

PL |

RL |

||

| 1 | Body,Bonnet | QT450-10 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Disc | WCB | CF8 | CF8M | CF3 | CF3M | |

| 3 | Stem | 1Cr13 | 2Cr13 | 1Cr18Ni9 | 1Cr18Ni12Mo2Ti | 00Cr18Ni10 | 00Cr17Ni14Mo2 |

| 4 | Liner/Seat | PTFE(F4)PCTFE(F3)FEP(F46)PFA(solubleF4)PP Po | |||||

| 5 |

Fasteners |

2Cr13 | 1Cr18Ni9 | 1Cr18Ni12Mo2Ti | 00Cr18Ni10 | 00Cr17Ni14Mo2 | |

| 6 | Packing | PTFE(F4) |

PTFE(F4) |

PTFE(F4) |

|||

| 7 | Gland | WCB | CF8 | CF8M | CF3 | CF3M | |

| 8 | Stents | WCB |

CF8 |

CF8 |

|||

| 9 | Bolt | 35 |

1Cr17Ni2 |

1Cr18Ni9Ti |

|||

| 10 | Nut | 45 |

0Cr18Ni9 |

0Cr18Ni9 |

|||

|

Dimensions connection size and weight |

||||||||||||

|

Nominal diameter |

Standard values |

Reference |

||||||||||

| DN(mm) | NPS(in) | L | D | D1 | D2 | f | b | z-φd | Do | H | H1 | W(kg) |

| 40 | 1 1/2 | 106 | 150 | 110 | 85 | 3 | 18 | 4-18 | 160 |

|

140 | 10 |

| 50 | 2 | 108 | 165 | 125 | 100 | 3 | 20 | 4-18 | 200 |

|

160 | 12 |

| 65 | 2 1/2 | 112 | 185 | 145 | 120 | 3 | 20 | 4-18 | 250 |

|

165 | 14 |

| 80 | 3 | 114 | 200 | 160 | 135 | 3 | 22 | 4-18 | 250 |

|

170 | 16 |

| 100 | 4 | 127 | 220 | 180 | 155 | 3 | 24 | 8-18 | 300 |

|

180 | 18 |

| 125 | 5 | 140 | 250 | 210 | 185 | 3 | 24 | 8-18 | 300 |

|

275 | 20 |

| 150 | 6 | 140 | 285 | 240 | 210 | 3 | 24 | 8-23 |

|

200 | 295 | 38 |

| 200 | 8 | 152 | 340 | 295 | 265 | 3 | 26 | 8-23 |

|

200 | 320 | 74 |

| 250 | 10 | 165 | 390 | 350 | 320 | 3 | 28 | 12-23 |

|

240 | 385 | 105 |

| 300 | 12 | 178 | 440 | 400 | 368 | 4 | 28 | 12-23 |

|

240 | 390 | 142 |

| 350 | 14 | 190 | 500 | 460 | 428 | 4 | 30 | 16-23 |

|

240 | 460 | 179 |

| 400 | 16 | 216 | 565 | 515 | 482 | 4 | 32 | 16-25 | - | 280 | 510 | 220 |

| 450 | 18 | 222 | 615 | 565 | 532 | 4 | 32 | 20-25 |

|

280 | 540 | 268 |

| 500 | 20 | 229 | 670 | 620 | 585 | 4 | 34 | 20-25 |

|

320 | 570 | 378 |

| 600 | 24 | 267 | 780 | 725 | 685 | 5 | 36 | 20-30 |

|

320 | 660 | 608 |

| 700 | 28 | 292 | 895 | 840 | 800 | 5 | 40 | 20-30 |

|

360 | 710 | 1050 |

| 800 | 32 | 318 | 1010 | 950 | 905 | 5 | 44 | 24-34 |

|

360 | 780 | 1320 |

| 900 | 36 | 330 | 1110 | 1050 | 1005 | 5 | 46 | 28-34 |

|

380 | 885 | 1795 |

| 1000 | 40 | 410 | 1220 | 1160 | 1110 | 5 | 50 | 28-34 |

|

400 | 990 | 1900 |

| 1200 | 48 | 254 | 1450 | 1380 | 1325 | 5 | 56 | 32-41 |

|

|

|

1 |

PN 1.6Mpa

|

Dimensions connection size and weight |

||||||||||||

|

Nominal diameter |

Standard values |

Reference |

||||||||||

| DN(mm) | NPS(in) | L | D | D1 | D2 | f | b | z-φd | Do | H | H1 | W(kg) |

| 40 | 1 1/2 | 106 | 150 | 110 | 85 | 3 | 18 | 4-18 | 160 |

|

140 | 10 |

| 50 | 2 | 108 | 165 | 125 | 100 | 3 | 20 | 4-18 | 200 |

|

160 | 12 |

| 65 | 2 1/2 | 112 | 185 | 145 | 120 | 3 | 20 | 4-18 | 250 |

|

165 | 13 |

| 80 | 3 | 114 | 200 | 160 | 135 | 3 | 22 | 8-18 | 260 |

|

170 | 14 |

| 100 | 4 | 127 | 220 | 180 | 155 | 3 | 24 | 8-18 | 300 |

|

180 | 16 |

| 125 | 5 | 140 | 250 | 210 | 185 | 3 | 26 | 8-18 | 300 |

|

275 | 18 |

| 150 | 6 | 140 | 285 | 240 | 210 | 3 | 28 | 8-23 |

|

200 | 295 | 42 |

| 200 | 8 | 152 | 340 | 295 | 265 | 3 | 30 | 12-23 |

|

200 | 320 | 78 |

| 250 | 10 | 165 | 405 | 355 | 320 | 3 | 32 | 12-25 |

|

240 | 385 | 120 |

| 300 | 12 | 178 | 460 | 410 | 368 | 4 | 34 | 12-25 |

|

240 | 390 | 145 |

| 350 | 14 | 190 | 520 | 470 | 428 | 4 | 38 | 16-25 |

|

240 | 460 | 202 |

| 400 | 16 | 216 | 580 | 525 | 482 | 4 | 40 | 16-30 | - | 280 | 510 | 235 |

| 450 | 18 | 222 | 640 | 585 | 532 | 4 | 44 | 20-30 |

|

280 | 540 | 368 |

| 500 | 20 | 229 | 705 | 650 | 585 | 4 | 46 | 20-34 |

|

320 | 570 | 420 |

| 600 | 24 | 267 | 840 | 770 | 685 | 5 | 54 | 20-41 |

|

320 | 660 | 750 |

| 700 | 28 | 292 | 910 | 840 | 800 | 5 | 54 | 20-41 |

|

360 | 710 | 1028 |

| 800 | 32 | 318 | 1020 | 950 | 905 | 5 | 54 | 24-41 |

|

380 | 780 | 1680 |

| 900 | 36 | 330 | 1120 | 1050 | 1005 | 5 | 54 | 28-41 |

|

400 | 885 | 1815 |

| 1000 | 40 | 410 | 1255 | 1170 | 1110 | 5 | 60 | 28-48 |

|

500 | 990 | 2050 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.

Previous :

D371F46 Fluorine lined rubber lined butterfly valvenext :

Aluminum Alloy Butterfly Valve SeriesIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported