XUVAL centric butterfly valves with fixed liner feature an outstanding seating concept. The rubber is injection molded directly on the valve body forming a permanent bond. Consequently, there is no risk of deformation or dislocation of the liner making the valves suitable under vacuum conditions. The combination of the profiled disc edge and the excellent XUVAL rubber quality ensures maximum durability of the liner.

Item NO.:

XU030Lead Time:

40DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

1Cast iron flange butterfly valve PN16

The butterfly valve is simple in structure, small in size and light in weight, and consists of only a few parts. And only need to rotate 90° can quickly open and close, simple operation, and the valve has good fluid control characteristics. The butterfly plate of the butterfly valve is installed in the diameter direction of the pipe. Within the cylindrical channel of the butterfly valve body, the disc butterfly plate rotates around the axis, and the rotation angle is between 0°~90°. When rotating to 90°, the valve plate is fully open. When the flange butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated through the valve is very small, so it has better flow control characteristics. Butterfly valve has elastic seal and metal seal two types of seal. Elastic sealing valve, sealing ring can be inlaid on the valve body or attached to the butterfly plate peripheral.

Characteristics:

The main features of the flange butterfly valve are:

1. small and light, easy to disassemble and repair, and can be installed in any position.

2. structure is simple, compact, operation torque is small ,90° turn on quickly.

3. flow characteristics tend to straight line, good regulation performance.

4. The valve stem is connected with the inner pin plate without possible leakage.

5. the outer circle of the butterfly plate is spherical shape, which improves the sealing performance and prolongs the service life of the valve.

6. seals can be replaced and sealed reliably to achieve two-way sealing.

7. butterfly plates can be sprayed on a customer's request, such as nylon or polytetrafluoroethylene.

8. the valve can be designed as flange connection and pair clamp connection.

9. drive mode can choose manual, electric or pneumatic.

The flange butterfly valve is suitable for temperature ≤120℃ or ≤150℃, nominal pressure ≤1.6 water supply and drainage, sewage, food, heating, gas, ship, water, electricity, metallurgy, energy system and light spinning, especially for two-way sealing and valve body corrosion prone occasions, for regulating flow and closure media.

Description of tables:

Application

Available Standard

BS5155

Working Pressure

1.6

Body Test Pressure

2.4

Seat Test Pressure

1.76

Reseat Pressure

1.6~0.35

| Main Parts and Material | |

|

Parts Name |

Material |

| Body |

Cast Iron |

| Seat Seating Face | Cast Iron |

| Disc | Ductile |

| Ring Fitted To Disc For Sealing | NBR |

|

shaft |

Rubber |

| shaft Bearings | DU |

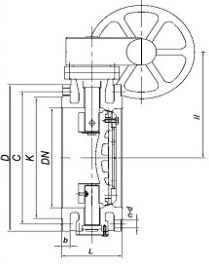

| Main Dimensions | |||||||

|

DN |

D |

C |

K |

b |

n-d |

L |

H |

| 100 | 220 | 180 | 156 | 19 | 8-φ19 | 127 | 170 |

| 150 | 285 | 240 | 200 | 19 |

8-φ23 |

140 | 220 |

| 200 | 340 | 295 | 266 | 20 |

12-φ23 |

152 | 270 |

| 250 | 405 | 355 | 319 | 22 |

12-φ28 |

165 | 330 |

| 300 | 460 | 410 | 370 | 24.5 |

12-φ28 |

178 | 360 |

| 350 | 520 | 470 | 429 | 26.5 | 16-φ28 | 190 | 370 |

| 400 | 580 | 525 | 480 | 28 |

16-φ31 |

216 | 380 |

| 450 | 640 | 585 | 548 | 30 |

20-φ31 |

222 | 495 |

| 500 | 715 | 650 | 609 | 31.5 |

20-φ34 |

229 | 535 |

| 600 | 840 | 770 | 720 | 36 |

20-φ37 |

267 | 615 |

| 700 | 910 | 840 | 794 | 39.5 |

24-φ37 |

292 | 662 |

| 800 | 1025 | 950 | 901 | 43 |

24-φ40 |

318 | 710 |

| 900 | 1125 | 1050 | 1001 | 46.5 |

28-φ40 |

330 | 832 |

| 1000 | 1255 | 1170 | 1112 | 50 |

28-φ43 |

410 | 915 |

| 1100 | 1355 | 1270 | 1218 | 53.5 |

32-φ43 |

470 | 1000 |

| 1200 | 1485 | 1390 | 1382 | 57 |

32-φ49 |

470 | 1060 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Cast iron wafer butterfly valve PN16next :

Three eccentric multi layer worm gear flange type butterfly valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported