Product use: D41X,D341X,D641X,D941X central line flange butterfly valves are used to regulate flow and cut off medium in water supply and drainage and gas pipelines of food,pharmaceutical, chemical,petroleum,electric power,light textile,papermaking,etc.with nominal pressure ≤ 1.6Mpa.

Item NO.:

XUVAL77-24Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

blueMOQ:

10

D641X central line flange pneumatic butterfly valve

Product use:

D41X,D341X,D641X,D941X central line flange butterfly valves are used to regulate flow and cut off medium in water supply and drainage and gas pipelines of food,pharmaceutical, chemical,petroleum,electric power,light textile,papermaking,etc.with nominal pressure ≤ 1.6Mpa.

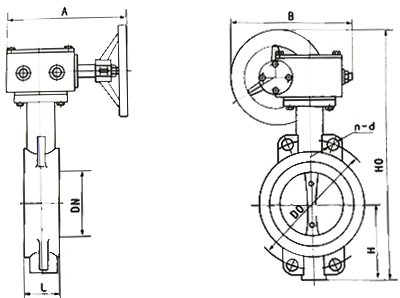

Structure diagram:

Valve model:

The models of central line flange pneumatic butterfly valves are:D641X-10,D641F-10,D641X-16,D641F-16,etc.

Product features:

1. The design is novel, reasonable, unique in structure, light in weight, convenient in operation and quick in opening and closing.

2. The elastic seal is produced by torque.

3. The sealing part can be adjusted and replaced, and the sealing performance is reliable.

4. The drive mode is turbine drive, electric drive and pneumatic drive.

Executive standard:

Design Code: GB / T 12238

Structure length: GB / T 12221

Flange connection: GB / T 9113

Test and inspection: GB / T 13927

Performance parameter:

D341X-10

D641X-10

D941X-10

Model of butterfly valve with central line flange

D341X-16

D341F-10

D341F-16

D641X-16

D641F-10

D641F-16

D941X-16

D941F-10

D941F-16

Working pressure(MPa)

1.0~1.6 (PN10-PN16)

Applicable temperature(℃)

≤180℃

Applicable medium

Air,water,steam,gas,oil,etc

Material

Valve body

Cast iron ductile iron carbon steel stainless steel aluminum alloy

Disc

Cast iron ductile iron carbon steel stainless steel aluminum alloy

Stem

2Cr13 F304 F316

Sealing surface

Rubber NBR EPDM PTFE

Filler

Flexible graphite PTFE

Main connection external dimension:

Nominal diameter

Length

Dimensions

Connection size

Weight

kg

0.6MPa

1.0MPa

1.6MPa

MM

L

H

H0

A

B

D

D1

D2

N-D

D

D1

D2

N-D

D

D1

D2

N-D

50

108

82.5

338

180

65

140

110

88

4-14

165

125

99

4-18

165

125

99

4-18

14

65

112

92.5

358

180

65

160

130

108

4-14

185

145

118

4-18

185

145

118

4-18

16

80

114

100

413

245

72

190

150

124

4-18

200

160

132

8-18

200

160

132

8-18

17

100

127

110

428

240

72

210

170

144

4-18

220

180

156

8-18

220

180

156

8-18

21

125

140

125

444

240

72

240

200

174

8-18

250

210

184

8-18

250

210

184

8-18

27

150

140

142.5

553

350

93

265

225

199

8-18

285

240

211

8-22

285

240

211

8-22

29

200

152

170

678

350

93

320

280

254

8-18

340

295

266

8-22

340

295

266

12-22

50

250

250

197.5

742

550

350

375

335

309

12-18

395

350

319

12-22

405

355

319

12-26

69

300

270

222.5

803

600

350

440

395

363

12-22

445

400

370

12-22

460

410

370

12-26

91

350

290

252.5

866

600

350

490

445

413

12-22

505

460

429

16-22

520

470

429

16-26

110

400

310

282.5

940

600

350

540

495

463

16-22

565

515

480

16-26

580

525

480

16-30

138

450

330

307.5

995

750

380

595

550

518

16-22

615

565

530

20-26

640

585

548

20-30

175

500

350

335

1058

750

380

645

600

568

20-22

670

620

582

20-26

715

650

609

20-33

210

600

390

390

1163

750

380

755

705

667

20-26

780

725

682

20-30

840

770

720

20-36

275

700

430

447.5

1283

750

380

860

810

772

24-26

895

840

794

24-30

910

840

794

24-36

530

800

470

507.5

1398

750

380

975

920

878

24-30

1015

950

901

24-33

1025

950

901

24-39

590

900

510

557.5

1498

1250

380

1075

1020

978

24-30

1115

1050

1001

28-33

1125

1050

1001

28-39

1400

1000

550

615

1608

1500

580

1175

1120

1078

28-30

1230

1160

1112

28-36

1255

1170

1112

28-42

1650

1200

630

727.5

1876

1500

580

1405

1340

1295

32-33

1455

1380

1328

32-39

1485

1390

1328

32-48

2140

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

SD943H electric telescopic butterfly valvenext :

SD341X/F/H SD641X/F/H SD941X/F/H telescopic butterfly valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported