H61Y-200, H61Y-250, and H61Y-320 high-pressure power station check valve branch pipes have welded structures at both ends, and the welded joints can be made according to standards or user requirements. They are suitable as devices to prevent medium backflow in high-temperature and high-pressure water, steam, oil, and superheated steam pipelines in thermal power plants, petrochemicals, metallurgy, and other industries. One is an imported type that follows the standards of ANSIB16.34 and JIS E101; Another type is the national standard type of Jb3595 standard. The temperature and pressure levels it follows are consistent, and there is a certain exchange relationship in some pipelines. The central part adopts a pressure self tightening type without a valve cover, which has good sealing performance under high temperature and pressure conditions. There are two types of materials for self sealing rings: one is low-carbon steel, and the other is flexible graphite clamp 316 wire (mesh). Weld the sealing surface with drill based hard alloy. The processed pure metal layer is ≥ 3mm, which has wear resistance, high temperature resistance, corrosion resistance, scratch resistance, and long service life.

Item NO.:

XUVAL88-319Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TT

High pressure power station check valve

Execution standards:

1. Design, manufacturing, and acceptance shall be in accordance with the standards of ANSIB16.34 API6DGB12236 E101, JB/T3595, and DL/T531 for thermal power generation valves.

2. The length of the structure shall be in accordance with E101, JB/T2766, GB/T15188.1, ANSIB16.10GB12221 standards or as required by the user.3. The pressure temperature level shall be in accordance with E101, JB/T3595 API598GB9131 standards.

4. Welding groove size shall be in accordance with GB12224, JB/T3595, ASME B16.25, and ANSIB16.25 standards, or according to user piping size requirements

Performance specifications:

| Nominal pressure PN (MPa) | Test pressure Ps (MPa) | Working pressure | Working temperature (degrees) | Applicable Medium | |||

| Strength | Sealing (liquid) | P54 | P55 | P57 | |||

| 10 | 15 | 11 | ≤425 | Water, steam, oil products | |||

| 16 | 24 | 17.6 | |||||

| 20 | 30 | 22 | |||||

| 25 | 37.5 | 27.5 | |||||

| 32 | 48 | 36 | |||||

| P5410 | 30 | 22 | 10 | ≤540 | Steam | ||

| P5414 | 37.5 | 27.5 | 14 | ||||

| P5417 | 48 | 36 | 17 | ||||

| P5510 | 37.5 | 27.5 | 10 | ≤550 | |||

| P5514 | 48 | 36 | 14 | ||||

| P5517 | 53 | 39 | 17 | ||||

| P5710 | 48 | 36 | 10 | ≤570 | |||

| P5714 | 55 | 40 | 14 | ||||

| P5717 | 60 | 44 | 17 | ||||

Structural features:

1. The valve disc is quenched as a whole and can move up and down on the valve body. When the medium flows back, the valve disc automatically closes by leveraging the medium pressure and spring.

2. The valve body and valve cover are both die forgings.

3. The sealing surface on the valve seat is made of cobalt based hard alloy plasma spray welding surface. Good wear resistance and scratch resistance.

4. Check valves should be installed on horizontal pipelines with medium flowing from bottom to top (normal flow).

Main component materials:

| Model | Part Name | |||||||

| Valve Body | Valve Disc | Spring | Valve Stem | Filler | Platen | Bonnet | Locking Nut | |

| H61Y-250 | Carbon Steel | Carbon Steel | Spring Steel | Stainless Steel | Flexible graphite | Carbon Steel | Carbon Steel | High quality carbon steel |

| H61Y-320 | ||||||||

| H61Y-P54100V | Chromium vanadium steel | Chromium vanadium steel | Spring Steel | Chromium vanadium steel | Flexible graphite | Chromium vanadium steel | Chromium vanadium steel | Chrome key steel |

| H61Y-P57170V | ||||||||

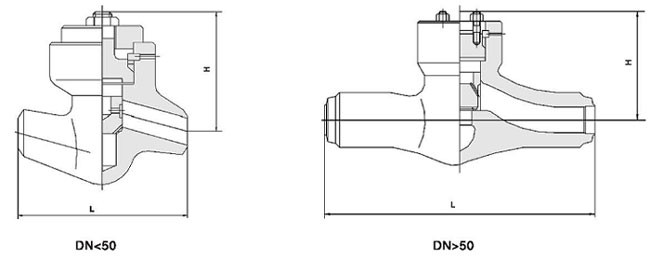

Structural diagram:

Installation dimensions and weight:

| GB 25.0MPa | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| GB 32.0MPa | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P54140V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P54170V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

| P57170V | ||||||||||

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| L | 120 | 170 | 170 | 170 | 200 | 230 | 350 | 326 | 470 | 560 |

| H | 155 | 200 | 210 | 210 | 245 | 270 | 300 | 410 | 370 | 420 |

| Wt | 2.5 | 8.5 | 9 | 10 | 14 | 21 | 28 | - | - | - |

Previous :

H76W Double Disc Butterfly Check Valvenext :

Clamp angle check valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported