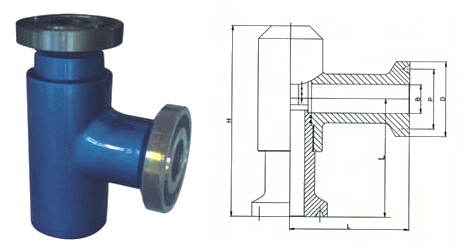

H83H and H83Y clamp angle check valves are high hardness valve discs made of stainless steel material, matched with high hardness stainless steel valve seats. They use face contact sealing, reliable sealing performance, and durability Capable of designing and manufacturing various types of valves in accordance with standards such as GB, ANSI, API, DIN, BS, JIS, etc. This series of valves is suitable for water, oil, natural gas and other pipelines with a working pressure of ≥ 45MPa and a working temperature of ≤ 120 ℃. It is used to control the one-way opening and closing of the medium to prevent backflow of the medium.

Item NO.:

XUVAL88-317Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1High pressure clamp angle check valve is suitable for pipelines with nominal pressure of PN1.6~42.0MPa and working temperature of -29~550 ℃ in various working conditions such as petroleum, chemical, and thermal power plants. Applicable media include water, oil, steam, etc.

Structural characteristics of high-pressure clamp angle check valve:

1. The selection of materials is meticulous, in accordance with relevant domestic and foreign standards, and the overall quality of the materials is high.

2. The sealing pair is advanced and reasonable, and the sealing surfaces of the valve disc and valve seat are made of iron-based alloy or Stellite cobalt based hard alloy overlay welding. It has good wear resistance, high temperature resistance, corrosion resistance, scratch resistance, and long service life.

3. The product is designed and manufactured according to the national standard GB/T12235.

4. Various piping flange standards and flange sealing types can be used to meet various engineering needs and user requirements.

5. The valve body material variety is complete, and the gasket can be reasonably selected according to actual working conditions or user requirements, which can be suitable for various pressure, temperature, and medium working conditions.

We can design and manufacture check valves with different structural and connection forms according to user requirements, to be used in conjunction with various equipment.

Standard specification for high-pressure clamp angle check valves:

Design and Manufacturing GB/T12235/Connection End Dimensions, Structural Lengths GB/T12221

Flange Dimensions JB/T79/Inspection and Testing JB/T9092

Materials: Carbon steel GB/T12229/Stainless steel GB/T12230

Alloy steel Q/ZB66/Standard GB/T12220/Supply JB/T7928

Main appearance and connection dimensions:

| Nominal Pressure | Nominal Diameter | Size (mm) | |||

| PN(MPa) | DN(mm) | L | L1 | DO | D1 |

|

16

20

25

35

40

|

40 | 265 | 420 | 36 | 60 |

| 50 | 267 | 420 | 45 | 73 | |

| 65 | 295 | 450 | 58 | 89 | |

| 80 | 355 | 540 | 72 | 108 | |

| 40 | 265 | 420 | 36 | 60 | |

| 50 | 267 | 420 | 45 | 73 | |

| 66 | 295 | 450 | 58 | 89 | |

| 88 | 355 | 540 | 72 | 108 | |

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported