Design and Manufacturing: GB122239 Structural length: GB12221, JB1688 Flange connection size: GB4216, JB78 G6B41W unlined diaphragm valve G6B41J rubber lined pneumatic diaphragm valve, normally open diaphragm valve

Item NO.:

XUVAL88-280Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1Pressure rating: PN0.6, 1.0, 1.6

Main component materials

Valve body: cast iron, ductile iron, carbon steel, stainless steel

Valve cover: cast iron, ductile iron, carbon steel, stainless steel

Lining: Unlined, rubber

Diaphragm: Rubber

Valve disc: cast iron, carbon steel

Cylinder: ductile iron

Pistons: carbon steel

Valve stem: carbon steel

Handwheel: cast iron

test

Lining layer: Electric spark detection

Testing and inspection according to GB/T13297 standard

Nominal pressure: PN (Mpa)

Valve body: PN × one point five

Sealing: PN × one point one

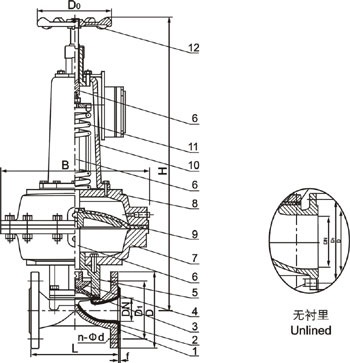

Parts list: 1. Valve body 2. Valve body lining 3. Diaphragm 4. Disc 5. Lower valve stem 6. Valve cover 7. Cylinder 8. Pistons 9. Spring 10. Cylinder cover 11. Upper valve stem 12. Handwheel

Main dimensions and weight

|

DN

mm

|

Nominal pressure

MPa

|

Working pressure

MPa

|

L

(mm)

|

D

(mm)

|

D1

(mm)

|

n-φd

(mm)

|

F

(mm)

|

H1

(mm)

|

H2

(mm)

|

D0 | B |

Air pressure

MPa

|

Air source connector

in

|

Gas consumption

cm3

|

Weight |

| (mm) | |||||||||||||||

| 15 | 0.6 | 0.6 | 125 | 95 | 65 | 4-14 | 2 | - | - | - | - | - | - | - | - |

| 20 | 139 | 105 | 75 | 4-14 | 2 | - | - | - | - | - | - | - | - | ||

| 25 | 145 | 115 | 85 | 4-14 | 2 | 306 | 320 | 120 | 94 | 0.4 | 10×1 | 2.395×102 | 7.5 | ||

| 32 | 160 | 140 | 100 | 4-18 | 2 | 410 | 430 | 140 | 120 | 0.4 | 12×1.25 | 6.082×102 | 14.5 | ||

| 40 | 180 | 150 | 110 | 4-18 | 3 | 415 | 435 | 140 | 120 | 0.4 | 12×1.25 | 6.082×102 | 16 | ||

| 50 | 210 | 165 | 125 | 4-18 | 3 | 463 | 488 | 160 | 185 | 0.4 | 12×1.25 | 1.235×102 | 24.5 | ||

| 65 | 250 | 185 | 145 | 4-18 | 3 | 620 | 660 | 160 | 245 | 0.5 | 16×1.5 | 3.725×102 | 30 | ||

| 80 | 300 | 200 | 160 | 4-18 | 3 | 627 | 687 | 200 | 245 | 0.5 | 16×1.5 | 3.725×103 | 51.5 | ||

| 100 | 350 | 220 | 180 | 8-18 | 3 | 719 | 769 | 240 | 330 | 0.5 | 16×1.5 | 9.458×103 | 86.5 | ||

| 125 | 400 | 250 | 210 | 8-18 | 3 | 804 | 872 | 320 | 380 | 0.5 | 20×1.5 | 1.409×104 | 133 | ||

| 150 | 460 | 285 | 240 | 8-22 | 3 | 920 | 1000 | 320 | 470 | 0.5 | 20×1.5 | 2.868×104 | 196.5 | ||

| 200 | 0.4 | 570 | 340 | 295 | 8-22 | 4 | 1145 | 1265 | 400 | 470 | 0.5 | 20×1.5 | 4.619×104 | 279.5 | |

| 250 | 680 | 395 | 350 | 12-22 | 4 | - | - | - | - | - | - | - |

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported