Brief introduction of diaphragm valve: G6K41J normally open pneumatic rubber-lined diaphragm valve is a special form of shut-off valve. Its opening and closing part is a diaphragm made of soft material, which separates the inner cavity of the valve body from the inner cavity of the bonnet, so that the valve body, The valve clack and valve stem are not corroded by the medium, and no medium will be generated. The normally open pneumatic rubber-lined diaphragm valve is used to change the passage section and the flow direction of the medium, and has the functions of diversion, cut-off, adjustment, throttling, check, diversion or overflow. The valve can control the flow of water, steam, oil, gas, mud, various corrosive media, liquid metal and radioactive fluid.

Item NO.:

XUVAL77-57Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

GreenMOQ:

10G6k41J pneumatic rubber-lined diaphragm valve (normally open)

The characteristics of the diaphragm valve are as follows:

The most prominent feature is that the diaphragm separates the inner cavity of the lower valve body from the inner cavity of the upper valve cover, so that the valve stem, valve clack and other parts located above the diaphragm are not corroded by the medium, and the packing seal structure is omitted, and no medium leakage occurs. .

1. Diaphragm made of soft seal such as rubber or plastic has good sealing performance. Since the diaphragm is a vulnerable part, it should be replaced regularly according to the characteristics of the medium.

2. Due to the limitation of the diaphragm material, the diaphragm valve is suitable for occasions with low pressure and relatively low temperature.

3. Diaphragm valves can be divided into six types according to their structure: house diaphragm valve, direct-flow diaphragm valve, stop diaphragm valve, straight-through diaphragm valve, gate diaphragm valve and right-angle diaphragm valve; the connection form is usually flange connection ; According to the driving mode, it can be divided into three types: manual, electric and pneumatic, among which pneumatic driving is divided into three types: normally open, normally closed and reciprocating.

Structural features and working principle of pneumatic rubber-lined diaphragm valve:

1. The biggest difference between this valve and other valves is that it adopts a structure without a stuffing box; the rubber diaphragm can completely isolate the corrosive medium in the flow channel from all the driving parts, thereby preventing the usual "running and risking" of the valve. , Drip, leak" and other disadvantages.

2. Since the flow path of the diaphragm valve is smooth and the flow resistance is small, a larger flow rate can be obtained.

3. Depending on the surface of the inner cavity of the rubber diaphragm valve, there are a variety of rubbers to choose from. Therefore, it has superior corrosion resistance.

4. Because the seal is a flexible rubber diaphragm. Therefore, it also has better sealing and minimal closing force.

5. This valve is composed of valve body, valve cover, valve clack, valve stem, diaphragm and other driving parts.

6. The opening and closing of the valve is achieved by rotating the hand wheel. This valve is marked on the upper end of the valve cover with a display color that can see the opening or closing position of the valve to indicate the opening and closing stroke of the valve. When the handwheel is placed clockwise, the handwheel will move down, and the valve disc will then drive the diaphragm down to cut off the passage; otherwise, the valve will open and the color will be revealed.

7. This valve adopts the standard: in accordance with the provisions of GB12239, and meets the requirements of BS5156.

Pneumatic rubber-lined diaphragm valve uses and main performance

specifications:

1. This series of diaphragm valves can be applied to different fluid medium pipelines at different temperatures according to different visual wrapping materials, as an opening and closing mechanism to control the flow of the medium.

2. The recommended application range of various visual wrap materials:

|

Depending on the wrapping material (code name) |

Proper temperature |

Applicable medium |

|

Hard rubber (NR) |

-10℃~85℃ |

In addition to strong oxidants (such as organic solvents such as acid, chromic acid, concentrated sulfuric acid and hydrogen peroxide), hydrochloric acid, fluorosilicic acid, formic acid and phenolic acid, hydrochloric acid, 30% sulfuric acid, 50% hydrofluoric acid, 80% phosphoric acid, alkalis, salts, metal plating solution, sodium hydroxide, potassium hydroxide, neutral salt solution, 10% sodium hypochlorite, wet chlorine, ammonia, most alcohols, organic acids and aldehydes, etc. |

|

Soft rubber (BR) |

-10℃~85℃ |

Has good wear resistance. Mainly used for sulfuric acid below 50%, sodium hydroxide, potassium hydroxide, neutral salt bath solution and ammonia solution, cement, clay, cinder ash, granular chemical fertilizer and solid fluid with strong abrasiveness, various concentrations of viscous liquid Wait. |

|

Butyl rubber (IIR) |

-10℃~120℃ |

Corrosion and wear resistance. It can withstand most organic acids, alkalis and hydroxide compounds, inorganic salts and inorganic acid element gases, alcohols, aldehydes, ethers, ketones, esters, etc. |

|

Neoprene |

(CR)-10℃~120℃ |

Animal oil, vegetable oil, inorganic lubricating oil and corrosive mud with a wide range of pH value have good abrasion resistance. |

|

Cast iron ignores the wrap |

-40℃~100℃ |

Non-corrosive medium |

Recommended use range of diaphragm material for pneumatic rubber-lined diaphragm valve:

Diaphragm material (code name)

Suitable temperature

Applicable medium

Butyl rubber (Grade B)

-40℃~100℃

Good acid and alkali resistance. 85% sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, charged alkali and various esters.

Natural rubber (Q grade)

-50℃~100℃

Used to purify water, inorganic salts, and dilute inorganic acids.

The main performance parameters of the diaphragm material of the pneumatic rubber-lined diaphragm valve:

Nominal diameter

Working pressure WP (Mpa)

Test pressure (Mpa)

Test temperature (℃)

Seal

Strength

EG41JW-16

20-50

1.6

1.76

2.4

EG41JW-10

65-200

1.0

1.1

1.5

Material of main parts of pneumatic rubber-lined diaphragm valve (normally open):

1

Body

Cast iron

2

Lining layer

Rubber

3

Diaphragm

Rubber

4

Disc

Cast iron

5

Bonnet

Cast iron

6

Stem

Carbon steel

7

Handwheel

Cast iron

Pneumatic rubber-lined diaphragm valve (normally open) main connection dimensions:

DN

Scope of application

Weight (kg)

L

D1

D

D0

Z

H

Medium

Type J

Type W

103

Type J

Type W

20

1.6

1.6

121

117

75

105

13.5

4

112

≤100

General corrosive

3

25

131

127

85

115

144

4.3

32

150

146

100

140

17.5

156

6.5

40

163

159

110

150

177

7.9

50

194

190

125

165

164.5

10.6

65

1.0

1.0

220

216

185

181.5

17.6

80

258

254

160

200

8

253

25.5

100

309

305

180

220

282

36.2

125

362

356

210

250

366.5

47.5

150

412

406

240

285

74

200

527

521

295

342

22

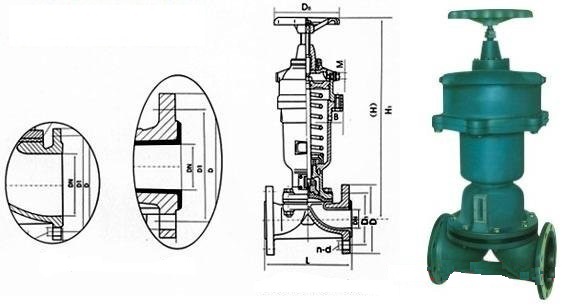

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported