1、 Overview Each water pump needs to be equipped with a bottom valve, which is usually installed below the water surface, while the above water bottom valve is installed above the water surface. It is a replacement product of the old bottom valve and is an ideal water diversion equipment and can also replace vacuum pumps and vacuum pumping devices. SSDF-l underwater bottom valve is composed of parts such as valve body, disc, piston rod, valve cover, positioning column, etc. Before starting the water pump, fill the suction pipe with liquid to make the pump have sufficient suction force. Suck the liquid into the valve, open the piston valve disc, and carry out the water supply operation. When the pump is stopped, the valve disc closes under the action of liquid pressure and its own gravity, thereby preventing the liquid from returning to the front of the pump. The design of the underwater bottom valve is reasonable, the manufacturing process is advanced, and the installation, use, and maintenance are convenient. And it has the advantages of low friction resistance, long service life, energy conservation, etc. It is widely used as a water pump supporting facility in industries such as petrochemical, chemical, textile, printing and dyeing, metallurgy, mining, drainage and irrigation, etc.

Item NO.:

XUVAL33-275Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiMOQ:

104. The self priming performance is reliable. As is well known, the sealing performance of old style bottom valves is poor, and there is often a problem of not being able to discharge water after stopping the pump. However, the above water bottom valve has a unique sealing effect, which can achieve no leakage and ensure the smooth operation of the next pump start. Therefore, in the design process, it is not necessary to consider choosing the water supply engineering scheme of the underwater pump house with a high investment due to not discharging water during the pump start.

Instructions for use

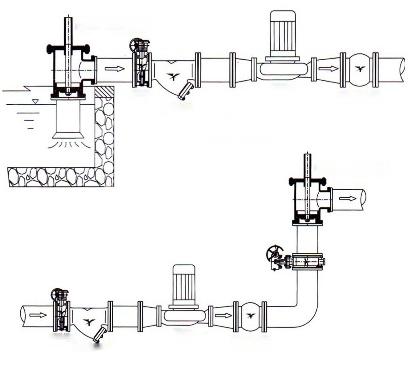

1. Installation requirements: Install at the turning point between the vertical and horizontal pipes of the water pump suction pipe, and ensure its vertical state during installation.

2. Start: After filling the horizontal pipe with water for the first time, start immediately, causing a semi vacuum state in the suction pipe, and suck the water into the vertical pipe to complete the process of pumping SSDF -. 1 water. The upper bottom valve. When the suction head is too large, it is necessary to repeat the water filling start several times, and then stop the pump. There is no need to fill the water before starting the pump.

3. Maintenance: Generally, maintenance is not necessary for use. When maintenance is required, simply open the valve cover on the water bottom valve and replace the rubber gasket. After the maintenance manual, start the pump according to the method of starting the pump for the first time.

4. If used in fluids with high acid and alkali concentrations, please choose stainless steel material for the above water bottom valve. At the same time, our factory can produce all plastic above water bottom valves or 316L (molybdenum titanium) material above water bottom valves according to user requirements.

6、 Installation diagram

next :

Water type bottom valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported