Pneumatic flange ball valves are widely used in various fields, such as water treatment, wastewater treatment, electroplating, chemical industry, semiconductor, energy industry, chemical industry, and other industries, with light weight and strong corrosion resistance. Their quality has been recognized by a large number of users.

Item NO.:

XUVAL33-247Lead Time:

30 DaysProduct Orgin:

CHINAShipping Port:

ShanghaiPayment:

100%TTMOQ:

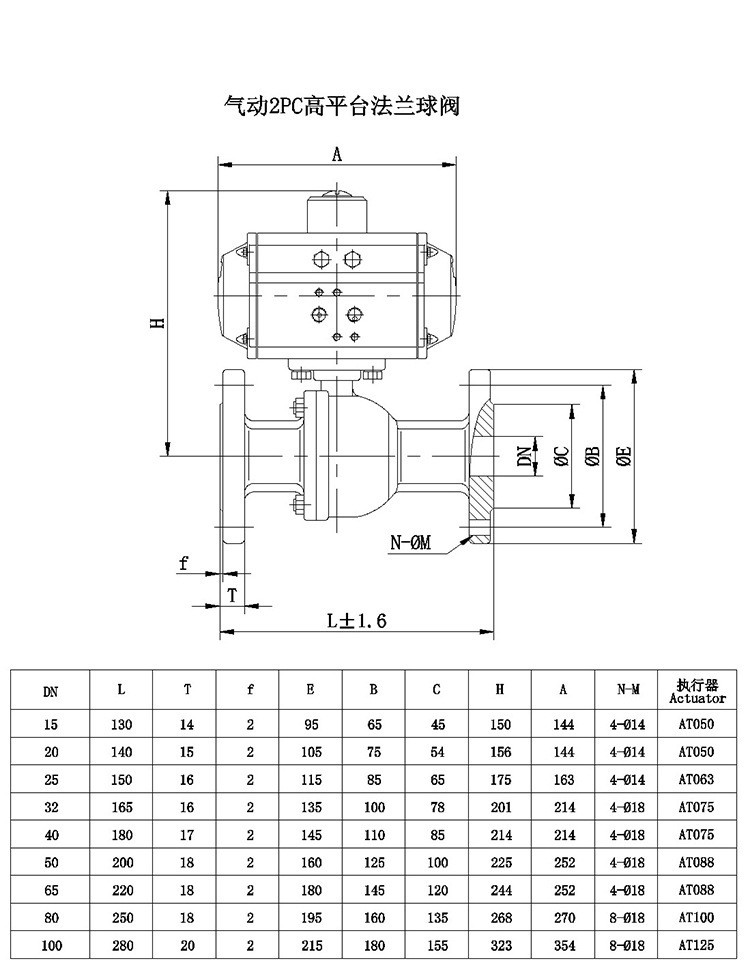

108. It has a wide range of applications, with diameters ranging from a few millimeters to several meters, and can be applied from high vacuum to high pressure.

Installation precautions:

(1) Before installation and use, pneumatic valves must undergo pre installation inspections and switch operation tests. Installation and use can only be carried out under normal operating conditions.

(2) The installation of pneumatic valves should be as concentric as possible with the pipeline flange and supported for fixation. The ball valve should not be subjected to other external forces to avoid damage to the middle seal of the valve and deformation of the valve. Causing ineffective valve opening and closing and damage to the valve, making it unusable.

(3) To ensure that the power supply provided by the balloon valve and pneumatic components is clean and free from oil and water as much as possible. The cleanliness should be less than 0.4 micrometers.

(4) Before connecting to the air source, it is necessary to clean the air supply pipeline, air source interface, switches and other components to prevent malfunctions caused by uncleaned pipelines carrying dirt and sand rushing into the pneumatic actuator unit.

(5) The connections of pneumatic actuators, solenoid valves, positioners, filters, pressure reducing valves, etc. can be made using copper or nylon pipes. To prevent dust and reduce noise, exhaust outlets should be equipped with silencers or silencing throttle valves.

(6) After installation, the pneumatic valve should be tested, and the pneumatic actuator should be pressurized to the rated value, with a pressure of 0.4-0.7 MPa. The pneumatic ball valve should be tested for opening and closing, and the valve's opening and closing status should be observed. It should rotate flexibly without jamming. If there is a blockage in the switch, the air pressure can be increased, and the valve can be adjusted to be flexible by repeatedly opening and closing.

(7) When installing and debugging switch type pneumatic valves, first use a manual device (the manual button on the solenoid valve) for debugging, and then power on for debugging after the action is normal.

(8) Pneumatic valves should be regularly maintained and the rotating parts of the valve stem should be refueled with oil every three months. Regularly drain and discharge water from the pneumatic execution unit and the air filter used in conjunction. Under normal circumstances, it should be inspected every six months and repaired once a year.

Previous :

Electric double acting ball valvenext :

Flange electric ball valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported