Overview of FQ all weather breathing valve: GFQ all-weather breathing valve is used on oil and liquid tank to remove the positive pressure and negative pressure gas in the tank, so that the liquid in and out of the tank is convenient. If there is no breathing valve on the tank, the liquid in and out of the tank has certain obstacles, which is likely to cause tank deformation and vibration. The product has reasonable design, simple structure and convenient use; It is an indispensable product of storage tank.

Item NO.:

XUVAL77-51Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

10GFQ all weather breathing valve

Performance and characteristics:

The shell is made of cast iron, cast steel and aluminum alloy with good corrosion resistance; The valve disc is made of Teflon material, with good low temperature resistance and antifreeze performance; Simple structure, easy maintenance, safety and convenience; GfQ all-weather breathing valve performance fully conforms to the Ministry of petroleum industry standard SY7511-87.

Application scope of GFQ all weather breathing valve:

GFQ all-weather breathing valve is suitable for storage of class a oil products with flash point lower than 28 ℃ and class B oil products with flash point lower than 60 ℃, such as gasoline, Benben, Benben, kerosene, light diesel, engine oil, crude oil and other oil products with the same properties. It can be used with a new type of corrugated flame arrester.

Instructions for GFQ all weather breathing valve:

The breathing valve is installed on the top of the tank to solve the problem of positive pressure and negative pressure gas in the tank, so that the liquid in and out of the tank is not hindered. When the external liquid enters the tank, there is a large amount of gas to breathe out (called positive pressure). If the liquid in the tank is exported to the outside, the tank must be sucked into the tank from the outside air (called negative pressure). If the breathing valve is closed automatically when it stops working, the liquid and gas in the tank will not leak out, so that the liquid quality in the tank is guaranteed.

GFQ all weather breathing valve maintenance:

In order to ensure the safety of breathing valve, check whether the guide rod and valve disc are flexible before use. This valve should be checked regularly (within 6 months) to see if the positive and negative valve discs of the vent are flexible and if the contact surface of the valve disc is damaged. If there is any damage, it should be repaired immediately. After maintenance, everything is normal and can be reused.

GFQ all weather breathing valve parts materials:

Body material

Carbon steel WCB, stainless steel 304, 316, aluminum alloy

Positive pressure disc material

Stainless steel 304, 316, aluminum alloy

Negative pressure disc material

Stainless steel 304, 316, PTFE

Ambient temperature (℃)

-30~60

Main technical parameters of GFQ all-weather breathing valve:

Class a positive pressure

355Pa(36mmH2O)

Negative pressure

295Pa(30mmH2O)

Class B positive pressure

980Pa(100mm H2O)

Negative pressure

295Pa(30mmH2O)

Class C positive pressure

1765Pa(180mmH2O)

Negative pressure

295Pa(30mmH2O)

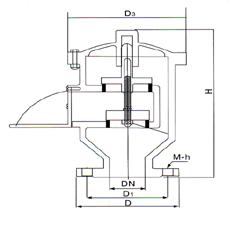

GFQ all weather breathing valve GB flange connection dimensions:

GB、JB

Specifications

Installation dimension (mm)

D1

D

D3

H

M-h

DN25

70

100

115

180

4×10

DN50

110

140

160

255

4×12

DN80

150

185

213

260

4×16

DN100

170

205

265

290

4×16

DN150

225

260

305

330

8×16

DN200

280

315

355

350

8×16

DN250

335

370

420

400

12×16

American standard flange connection all weather breathing valve dimensions:

ANSI, API and ASME are available for JIS standard

Specifications

Installation dimension (mm)

D1

D

D3

H

M-h

1"

79.5

108

115

180

4×15

2"

120.5

152

160

255

4×19

3"

152.5

190

213

260

4×19

4"

190.5

229

265

290

8×19

6"

241.5

254

305

330

8×22

8"

298.5

343

355

350

8×22

10"

362

406

420

400

12×25

Breathing valve classification:

The first one is to breathe or inhale when a certain pressure is reached; The other is designed as pure breathing without suction, which can be understood as two check valves with appropriate pressure instead. The second kind of breathing valve is similar to the one-way check valve. It can only exhale outward, but not inhale inward. When the pressure in the system rises, the gas will be vented outward through the breathing valve to ensure the constant pressure of the system. For tanks storing toxic substances, there is no breathing valve or activated carbon filter and other treatment devices. The breathing valve is generally used in atmospheric or low-pressure tanks, that is, only atmospheric and low-pressure tanks have breathing discharge, while high-pressure tanks have no discharge, no breathing loss and work loss. The main emissions of fixed roof tank are respiratory loss and work loss.

Selection of breathing valve:

1. For the requirements of installation position and temperature range, for example, all-weather breathing valve should be selected in cold area, and pipeline breathing valve should be selected for installation in pipeline. 2. The control pressure of mechanical breathing valve should be suitable for the pressure bearing capacity. 3. The specification of mechanical breathing valve shall meet the requirement of maximum oil breathing gas flow in and out of oil tank.

Product structure chart:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Lock balance valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported