Overview of ZMAN-16D pneumatic anti-spring low-temperature double-seat control valve: ZMAN-16D pneumatic anti-spring low-temperature double-seat control valve pneumatic film low-temperature control valve is a deformation product of single-seat and double-seat control valves. It is different from normal temperature in that it adopts a long-necked upper valve cover to make the packing work at normal temperature. It is suitable for the adjustment of the medium (such as liquid oxygen, liquid nitrogen, etc.) under the low temperature and strong state of -60~-250℃. To ensure the accuracy of adjustment, a positioner must be used.

Item NO.:

XUVAL77-98Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10ZMAN-16D pneumatic anti-spring low-temperature double-seat regulating valve

Structural principle of pneumatic low-temperature double-seat control valve:

The pneumatic low-temperature control valve is composed of a pneumatic film actuator and a low-temperature-resistant single-seat and double-seat control valve. The signal pressure from the regulator is input into the air chamber of the pneumatic membrane actuator to generate thrust, and the valve core is driven by the connecting rod. The change of the valve core position changes the flow cross-sectional area of the valve and realizes the adjustment of the medium flow.

Precautions for pneumatic low-temperature double-seat control valve:

1. It should be installed vertically on a horizontal pipeline. In special circumstances, when horizontal or inclined installation is required, support should generally be added. The circular board installed on the wall of the incubator should be parallel to the wall of the incubator.

2. It should be installed near the ground or floor for maintenance and repair. For those equipped with a positioner or handwheel mechanism, it should be ensured that the observation, adjustment and operation are convenient.

3. Generally, by-pass pipelines are set up so as to switch to manual operation when the automatic control system fails or is repaired, so as not to stop production.

4. When a handwheel mechanism is installed, manual operation can also be omitted when the bypass pipeline is installed, and it can also be used to limit the opening. When stopping use, the handwheel mechanism must be restored to the original neutral position to facilitate the normal operation of the automatic control system.

5. During installation, the flow direction of the medium should be consistent with the direction indicated by the valve body.

6. The pipeline should be cleaned of dirt and welding slag before installation. After installation, make it fully open, clean the pipeline, etc. and test the tightness of each connection.

Main technical indicators of pneumatic low-temperature double-seat control valve:

Single seat

20

25

32

40

50

65

80

100

125

150

200

Two-seater

25

32

40

50

65

80

100

125

150

200

Single seat

0.08

0.12

0.20

0.32

0.50

0.80

1.2

2.0

3.2

5.0

8

12

20

32

50

80

120

200

280

450

Two-seater

10

6

25

40

63

100

160

250

400

630

Flow characteristics

Straight line

Straight line; equal percentage

Equipped with actuator model

ZMA-2

ZMA-3

ZMA-4

ZMA-5

Journey

10

10

16

25

40

60

Mode of action

Air-closed (B), air-opened (K)

Spring pressure range KPa

Standard signal: 20~100; other signals; 40~200; 20~60; 60~100

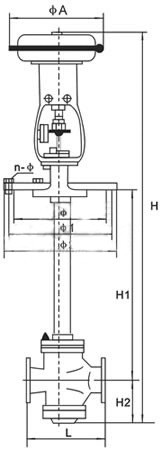

Outline structure drawing:

Main dimensions:

|

Nominal diameter DN (mm) |

|

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||

| A | 230 | 280 | 280 |

325 |

410 |

495 |

||||||||

|

|

135 | 235 | 235 | 255 | 280 | 310 | 345 | 370 | 430 | 470 | 550 | 660 | ||

| 1 | 160 | 260 | 260 | 285 | 305 | 340 | 375 | 405 | 460 | 525 | 590 | 700 | ||

| 2 | 190 | 290 | 290 | 315 | 335 | 370 | 410 | 440 | 490 | 560 | 630 | 740 | ||

| n-d | 6-12 | 8-14 | 8-14 | 8-14 |

8-16 |

10-16 | 10-18 | 12-18 |

16-18 |

20-18 | ||||

|

Single seat |

H |

L | 120 | 190 | 200 | 210 | 235 | 265 | 295 | 210 | 370 | 440 | 475 | 570 |

| H1=500 | 862 | 1006 | 1060 | 1066 | 1137 | 1152 | 1377 | 1390 | 1394 |

|

|

|

||

| H1=600 | 962 | 1106 | 1160 | 1166 | 1237 | 1252 | 1477 | 1490 | 1494 |

|

|

|

||

| H1=700 | 1062 | 1206 | 1260 | 1266 | 1337 | 1352 | 1577 | 1590 | 1594 | 1743 | 1751 | 1790 | ||

| H1=800 | 1162 | 1306 | 1360 | 1366 | 1437 | 1452 | 1677 | 1690 | 1694 | 1843 | 1851 |

|

||

| H1=900 | 1262 | 1406 | 1460 | 1466 | 1537 | 1552 | 1777 | 1790 | 1794 | 1943 | 1951 | 1990 | ||

| H1=1000 | 1362 | 1506 | 1560 | 1566 | 1637 | 1652 | 1877 | 1890 | 1894 | 2043 | 2051 | 2090 | ||

| H1=1100 |

|

|

|

|

|

|

|

|

|

2143 | 2150 | 2190 | ||

| H1=1200 |

|

|

|

|

|

|

|

|

|

2243 | 2250 | 2290 | ||

|

H2 |

32 | 58 | 112 | 118 | 129 | 144 | 178 | 191 | 195 | 243 | 251 | 290 | ||

|

Two-seater |

H |

L |

|

|

200 | 210 | 235 | 265 | 295 | 320 | 370 | 440 | 475 | 570 |

| H1=500 |

|

|

1065 | 1068 | 1147 | 1152 | 1387 | 1407 | 1419 |

|

|

|

||

| H1=600 |

|

|

1165 | 1168 | 1247 | 1252 | 1487 | 1507 | 1519 |

|

|

|

||

| H1=700 |

|

|

1265 | 1268 | 1347 | 1352 | 1587 | 1607 | 1619 | 1768 | 1778 | 1820 | ||

| H1=800 |

|

|

1365 | 1368 | 1447 | 1452 | 1687 | 1607 | 1719 | 1868 | 1878 | 1920 | ||

| H1=900 |

|

|

1465 | 1468 | 1457 | 1552 | 1787 | 1807 | 1819 | 1968 | 1978 | 2020 | ||

| H1=1000 |

|

|

1565 | 1568 | 1647 | 1652 | 1887 | 1907 | 1919 | 2068 | 2078 | 2120 | ||

| H1=1100 |

|

|

|

|

|

|

|

|

|

2168 | 2178 | 2220 | ||

| H1=1200 |

|

|

|

|

|

|

|

|

|

2268 | 2278 | 2320 | ||

|

H2 |

|

|

117 | 120 | 139 | 144 | 188 | 208 | 208 | 268 | 278 | 320 | ||

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

ZJSF/H pneumatic film three-way regulating valvenext :

ZDLPF46 electronic electric fluorine-lined bellows regulating valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported