D41W ventilation butterfly valve/D341W worm gear ventilation butterfly valve/D641W pneumatic ventilation butterfly valve/D941W electric ventilation butterfly valve is made of the same material as the valve body and processed into a sealing ring. Its applicable temperature depends on the material selection of the valve body, and the nominal pressure is ≤ 0.6MPa. It is generally suitable for regulating the flow rate of ventilation media in industrial, metallurgical, environmental and other pipelines.

Item NO.:

XUVAL88-310Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

1Main characteristics of ventilation butterfly valves

1. The design is novel, reasonable, and has a unique structure, with light weight and fast opening and closing.

2. Small operating torque, convenient operation, labor-saving and agile.

3. Adopting suitable materials to meet the different medium temperatures of low, medium, and high, as well as corrosive media.

Ventilation butterfly valve adopts standard

Design standard: GB/T12238-1989 JB/T8692-1998

Flange connection size: GB/T9115.1-2000

Structural length: GB/T12221-1989

Pressure test: GB/T13927-1992; JB/T9092-1999

Main technical parameters of ventilation butterfly valve

| Nominal Diameter | DN(mm) | 50~2000 | ||

| Nominal Pressure | PN(MPa) | 0.05 | 0.25 | 0.6 |

| Test Pressure | Strength Test | 0.075 | 0.375 | 0.9 |

| Sealing test | ≤ 1% Leakage Rate | |||

| Applicable Medium | Gas, dusty gas, flue gas, etc. | |||

| Driving Form | Manual, worm gear transmission, pneumatic transmission, electric transmission | |||

Material of main components of ventilation butterfly valve

| Part Name | Material |

| Valve Body | Special materials such as cast steel, stainless steel, chromium nickel molybdenum titanium steel, chromium molybdenum titanium steel, etc |

| Disc | Special materials such as cast steel, stainless steel, chromium nickel molybdenum titanium steel, chromium molybdenum titanium steel, etc |

| Sealing ring | Same as valve body |

| Valve stem | Carbon steel, 2Cr13, stainless steel, chromium nickel molybdenum titanium steel |

| Filler | Fluoroplastics, flexible graphite |

Selection and Applicable Temperature of Sealing Materials for Ventilation Butterfly Valves

| Material variety | Carbon steel | Low Temperature Carbon Steel | Aalloy Steel | Austenitic Stainless Steel | Chromium Molybdenum Steel | |

| Code | WCB | LCB | WC6 or WC9 | C5 or C12 | Chromium Cr-18 type e, 304, 316 | 12CrMoV |

| Maximum temperature resistance | 425℃ | 345℃ | 595℃ | 650℃ | 600℃ | 560℃ |

| Minimum temperature resistance e | -29℃ | -46℃ | -29℃ | -29℃ | -196℃ | -40℃ |

| Applicable working temperature | ≤425℃ | ≤345℃ | ≤595℃ | ≤650℃ | ≤600℃ | ≤560℃ |

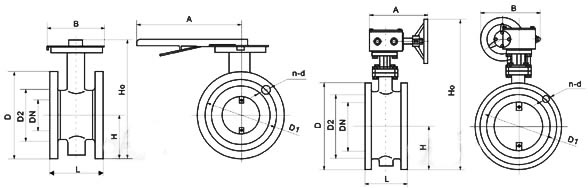

External dimensions of ventilation butterfly valve

| Nominal Diameter | Structure length | External dimensions | Connection size (standard value) | reference value | |||||||||||

| (Standard value) | (Reference value) | 0.05MPa and 0.25MPa | 0.6MPa | (kg) | |||||||||||

| mm | inch | L | H | H0 | A | B | D | D1 | D2 | n-d | D | D1 | D2 | n-d | |

| 50 | 2 | 108 | 70 | 286 | 125 | 193 | 140 | 110 | 88 | 4-18 | 140 | 110 | 88 | 4-14 | 14 |

| 65 | 2-21 | 112 | 80 | 306 | 125 | 193 | 160 | 130 | 108 | 4-18 | 160 | 130 | 108 | 4-14 | 15 |

| 80 | 3 | 114 | 95 | 334 | 125 | 193 | 190 | 150 | 124 | 4-18 | 190 | 150 | 124 | 4-18 | 17 |

| 100 | 4 | 127 | 105 | 354 | 125 | 193 | 210 | 170 | 144 | 4-18 | 210 | 170 | 144 | 4-18 | 20 |

| 125 | 5 | 140 | 120 | 384 | 125 | 193 | 240 | 200 | 174 | 8-18 | 240 | 200 | 174 | 8-18 | 25 |

| 150 | 6 | 140 | 132 | 409 | 125 | 193 | 265 | 225 | 199 | 8-18 | 265 | 225 | 199 | 8-18 | 29 |

| 200 | 8 | 152 | 160 | 593 | 165 | 183 | 320 | 280 | 254 | 8-18 | 320 | 280 | 254 | 8-18 | 47 |

| 250 | 10 | 165 | 187 | 650 | 165 | 283 | 375 | 335 | 309 | 12-18 | 375 | 335 | 309 | 12-18 | 67 |

| 300 | 12 | 178 | 220 | 715 | 165 | 283 | 440 | 395 | 363 | 12-22 | 440 | 395 | 363 | 12-22 | 78 |

| 350 | 14 | 190 | 245 | 814 | 175 | 334 | 490 | 445 | 413 | 12-22 | 490 | 445 | 413 | 12-22 | 96 |

| 400 | 16 | 216 | 270 | 863 | 175 | 334 | 540 | 495 | 463 | 16-22 | 540 | 495 | 463 | 16-22 | 130 |

| 450 | 18 | 222 | 297 | 918 | 175 | 334 | 595 | 550 | 518 | 16-22 | 595 | 550 | 518 | 16-22 | 142 |

| 500 | 20 | 229 | 322 | 1016 | 210 | 425 | 645 | 600 | 568 | 20-22 | 645 | 600 | 568 | 20-22 | 191 |

| 600 | 24 | 267 | 377 | 1128 | 210 | 425 | 755 | 705 | 667 | 20-26 | 755 | 705 | 667 | 20-26 | 230 |

| 700 | 28 | 292 | 430 | 1233 | 210 | 425 | 860 | 810 | 772 | 24-26 | 860 | 810 | 772 | 24-26 | 250 |

| 800 | 32 | 318 | 487 | 1344 | 210 | 425 | 975 | 920 | 878 | 24-30 | 975 | 920 | 878 | 24-30 | 320 |

| 900 | 36 | 330 | 537 | 1560 | 320 | 620 | 1075 | 1020 | 978 | 24-30 | 1075 | 1020 | 978 | 24-30 | 410 |

| 1000 | 40 | 410 | 587 | 1660 | 320 | 620 | 1175 | 1120 | 1078 | 28-30 | 1175 | 1120 | 1078 | 28-30 | 510 |

| 1200 | 48 | 470 | 687 | 1890 | 320 | 620 | 1375 | 1320 | 1280 | 32-30 | 1405 | 1340 | 1295 | 32-33 | 720 |

| 1400 | 56 | 530 | 760 | 2670 | 575 | 714 | 1575 | 1520 | 1480 | 36-30 | 1630 | 1560 | 1510 | 36-36 | 1270 |

| 1600 | 64 | 600 | 895 | 2810 | 575 | 714 | 1790 | 1730 | 1690 | 40-30 | 1830 | 1760 | 1710 | 40-36 | 1730 |

| 1800 | 72 | 670 | 995 | 3020 | 575 | 714 | 1990 | 1930 | 1890 | 44-30 | 2045 | 1970 | 1918 | 44-39 | 2750 |

| 2000 | 80 | 760 | 1095 | 3220 | 656 | 810 | 2190 | 2130 | 2090 | 48-30 | 2265 | 2180 | 2125 | 48-42 | 3050 |

Previous :

D81X stainless steel sanitary butterfly valvenext :

Single eccentric clamp handle butterfly valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported