Pneumatic diaphragm valve, also known as diaphragm globe valve, refers to a compression device that is equipped with a flexible diaphragm or a combination diaphragm in the valve body and valve cover, and its closed part is connected to the diaphragm. The valve seat can be a weir shaped or a straight channel wall. The flexible membrane or composite membrane of the diaphragm valve is surrounded by the control room. By injecting compressed air, natural gas, water, or other substances into the control room to generate pressure, the flexible or composite membrane is compressed and bent, and the cross-section of the membrane changes or even closes, thereby controlling the flow rate and feed. When the control pressure is about 2.5 bar higher than the pressure of the conveyed liquid, the diaphragm valve can seal gas, liquid, paste and powder liquids. High elasticity diaphragm can transport any material, especially powdered materials.

Item NO.:

XUVAL33-337Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

silveryMOQ:

1Diaphragm valves can basically prevent the above phenomena, greatly reduce the negative impact of production uncertainty, and effectively control and operate the entire system.

Technical Parameter:

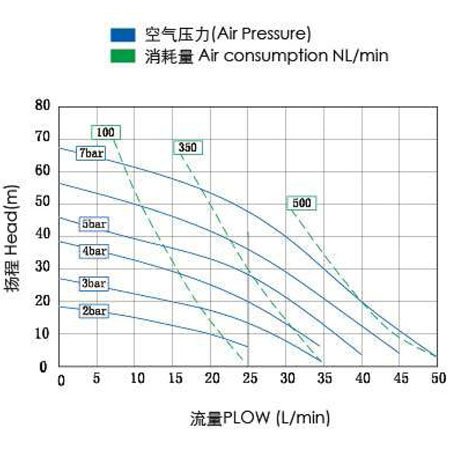

| Maximum working pressure | 100psi(0.7Mpa,7bar) |

| Maximum flow | 13.2gpm(50lpm) |

| Maximum reciprocating speed | 400cpm |

| Maximum siphon height | 4m |

| Maximum conveying of solid particles | 3/32in.(2.5mm) |

|

Maximum air consumption |

28scfm(0.672m³/min) |

| Air inlet size | 1/4in.npt(f) |

| Air outlet size | 1/4in.npt(f) |

| Fluid inlet size | 1/2and3/4in.npt(f)orbspt(f) |

| Fluid outlet size | 1/2and3/4in.npt(f)orbspt(f) |

| weight | Aluminum alloy pumpAluminumpump4.4kg |

| stainless steel pumpStainlesssteelpump6.8lg |

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported