Structural characteristics of single seat regulating valve, double seat regulating valve, and sleeve regulating valve

There are various types of regulating valve structures, each with its own characteristics. In engineering design, it should be determined based on factors such as on-site conditions (temperature, pressure, flow rate, pressure difference, installation position, etc.), fluid properties (viscosity, corrosiveness, saturation temperature, etc.), requirements of the regulating system (adjustable ratio, leakage rate, flow rate characteristics, etc.), and environmental requirements (noise, protection requirements, etc.). In general, lower priced ordinary regulating valves, such as single or double seat regulating valves and sleeve regulating valves, should be preferred. When these valves cannot meet the needs, other suitable regulating valves should be selected.

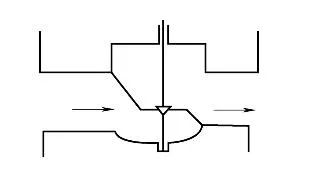

1. Single seat regulating valve

The single seat regulating valve (referred to as the single seat valve) (Figure 1) has a small leakage rate and is easy to ensure sealing, but its unbalanced force is large, especially in high pressure differential and large diameter situations, so it is suitable for low pressure differential and small diameter situations. In addition, when DN ≥ 25, the valve stem adopts a double guide structure and can be inverted. As long as a positive acting actuator is used, the conversion between air opening and air closing can be achieved.

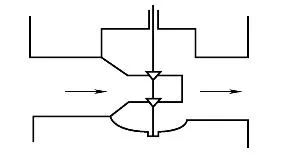

2. Double seat regulating valve

The double seat regulating valve (referred to as the double seat valve) (Figure 2) has two valve cores. The thrust direction of the fluid acting on the upper and lower valve cores is opposite, and the magnitude is basically the same, so the unbalanced force is small, and the allowable pressure difference is large. But when closed, it is difficult to ensure that the two valve cores of the double seat valve are closed at the same time, resulting in a large amount of leakage, especially when used in high-temperature situations. Due to the different thermal expansion of the valve core and valve body materials, leakage is more likely. Due to the complex flow path inside the valve, it is not suitable for high viscosity media. The direction of unbalanced force varies with the change of valve opening. When the opening is 60%~70%, an unstable zone will appear, and the valve core tends to oscillate, as shown in Figure 3.

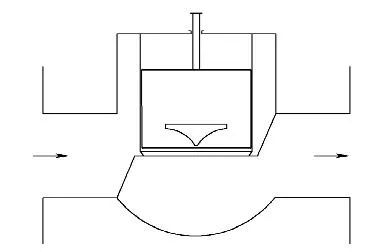

3. Sleeve type regulating valve

A sleeve type regulating valve (referred to as a sleeve valve) is a cylindrical sleeve installed inside the valve body, and a valve plug that can slide axially is assembled with the sleeve as the guide. The sleeve has a window hole with certain flow characteristics.

Sleeve type regulating valve:

By changing the flow area formed by the valve plug and sleeve window hole, the purpose of regulating flow can be achieved, as shown in Figure 4. The characteristics of this type of valve are good stability, belonging to a balanced structure with low unbalanced force (Figure 5), long guidance, stable operation, simple structure, convenient disassembly and assembly, and strong universality; Simply replace the sleeve to change the flow capacity and flow characteristics; Changing the internal components of the valve can become a single seat valve with minimal thermal expansion impact - the sleeve and valve core are made of the same material and have similar shapes, which can eliminate the impact of temperature changes and thus have a long lifespan. The sealing surface of the sleeve valve is separated from the throttling surface, and the high-speed fluid at the throttling port collides with each other, consuming energy inside the fluid instead of directly flushing the sealing surface of the valve like single and double seat valves. Therefore, in situations of high pressure difference, the lifespan of the sleeve valve is often much longer than that of single and double seat valves. This type of valve also has a certain degree of anti cavitation ability. Due to the medium at the bottom of the valve core, in the event of cavitation, bubbles burst and the resulting impact force acts on the space below the valve core. The impact energy does not act on the valve core, but is absorbed by the medium itself. The impact energy of single and double seat valves directly acts on the valve core. Therefore, the anti cavitation performance of sleeve valves is better than that of single and double seat valves. Due to the fact that the energy of the sleeve valve is mostly consumed in the sleeve, and the dynamic pressure energy is consumed in mutual impact, the noise is usually about 10dB lower than that of single and double seat valves; By changing the form of the sleeve, the noise level can be further reduced.

Categories

Recent Posts

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported