Structural characteristics and application of gas pressure reducing valve: This series of pressure reducing valve belongs to pilot piston pressure reducing valve. It consists of main valve and pilot valve. The main valve is mainly composed of valve seat, main valve disc, piston, spring and other parts.

Item NO.:

XUVAL77-43Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

10YK43X/F gas pressure reducing valve

Pilot valve is mainly composed of valve seat, disc, diaphragm, spring, adjusting spring and other parts. The outlet pressure is set by adjusting the spring pressure, the diaphragm is used to sense the outlet pressure change, and the pilot valve is opened and closed to drive the piston to adjust the flow area of the throttle part of the main valve, so as to realize the function of pressure reduction and stabilization. This product is mainly used in gas pipeline, such as air pressure reducing valve, nitrogen pressure reducing valve, oxygen pressure reducing valve, hydrogen pressure reducing valve, liquefied gas pressure reducing valve, natural gas and other gases.

YK43F gas pressure reducing valve (air pressure reducing valve, nitrogen pressure reducing valve, oxygen pressure reducing valve, hydrogen pressure reducing valve, liquefied gas pressure reducing valve, natural gas)

Model of gas pressure reducing valve:YK43F

Nominal diameter of gas pressure reducing valve: 15mm-500mm

Service pressure of gas pressure reducing valve: 1.6MPa-10MPa

Connection mode of gas pressure reducing valve: flange connection

Type of gas pressure reducing valve: spring type

Main function of gas pressure reducing valve: pressure reducing protection

Medium used for gas pressure reducing valve: Gas Pipeline

Material of gas pressure reducing valve: cast steel. Stainless steel

Standard of gas pressure reducing valve: standard of mechanical department or customized non-standard

Main technical parameters and performance indexes of gas pressure reducing valve:

Nominal pressure (MPa)

1.6

2.5

4.0

6.4

10.0

16.0

Shell test pressure (MPa)*

2.4

3.75

6.0

9.6

15.0

24

Sealing test pressure (MPa)

1.6

2.5

4.0

6.4

10.0

16.0

Maximum inlet pressure (MPa)

1.6

2.5

4.0

6.4

10.0

16.0

Outlet pressure range (MPa)

0.1~1.0

0.1~1.6

0.1~2.5

0.5~3.5

0.5~3.5

0.5~4.5

Pressure characteristic deviation (MPa) △ P2P

GB12246-1989

Flow characteristic deviation (MPa) P2G

GB12246-1989

Minimum pressure difference (MPa)

0.15

0.15

0.2

0.4

0.8

1.0

Leakage volume

X/F (polytetrafluoroethylene/rubber):OY(hard seal):GB12245-1989

Material of main parts of gas pressure reducing valve:

Part name

Material of parts

Valve body,bonnet,bottom cover

WCB/FCB*

Seat,disc

2Cr13/304*

Cylinder liner

2Cr13/25 (hard chromium plating)/304*

Piston

2Cr13/copper alloy/copper alloy*

Piston ring

Alloyed cast iron/para polyphenylene*

Guide valve seat and guide valve stem

2Cr13/304*

Diaphragm

1Cr18Ni9Ti

Main valve pilot valve spring

50CrVA

Adjusting spring

60Si2Mn

Gasket (X/F model)

Rubber/PTFE

Guide valve body and cover

25/304*

Flow coefficient of gas pressure reducing valve (Cv):

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Cv | 1 | 2.5 | 4 | 6.5 | 9 | 16 | 25 | 36 | 64 | 100 | 140 | 250 | 400 | 570 | 780 | 1020 | 1500 |

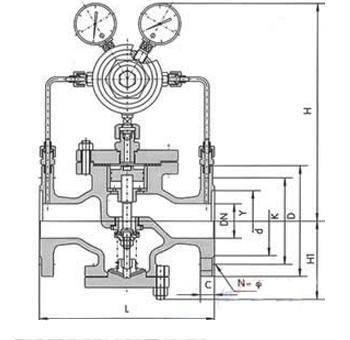

Product structure chart:

Dimension of gas pressure reducing valve (PN1.6-4.0):

Nominal diameter DN

Dimensions

L

H

H1

1.6/2.5MPa

4.0MPa

15

160

180

290

90

20

160

180

300

98

25

180

200

300

110

32

200

220

300

110

40

220

240

320

125

50

250

270

320

125

65

280

300

325

130

80

310

330

365

160

100

350

380

365

170

125

400

450

475

200

150

450

500

475

210

200

500

550

515

240

250

650

560

290

300

800

705

335

350

850

745

375

400

900

780

405

450

900

730

455

500

950

835

465

Dimension of gas pressure reducing valve (PN6.4-16.0):

Nominal diameter DN

Dimensions

L

H

H1

6.4MPa

10.0/16.0MPa

15

180

180

300

100

20

180

200

310

105

25

200

220

310

120

32

220

230

310

120

40

240

240

335

135

50

270

300

335

135

65

300

340

340

140

80

330

360

380

170

100

380

380

185

125

450

490

215

150

500

490

225

200

550

535

260

250

650

580

310

300

800

725

355

350

850

765

395

400

900

800

435

500

950

855

495

Pressure regulating steps of pressure reducing valve:

1. Close the gate valve in front of the pressure reducing valve, open the gate valve behind the pressure reducing valve, create downstream low pressure environment, rotate the adjusting screw counterclockwise to the top position (relative to the lowest outlet pressure), and then close the gate valve behind the pressure reducing valve.

2. Slowly open the gate valve in front of the pressure reducing valve to full open.

3. Slowly turn the adjusting screw clockwise to adjust the outlet pressure to the required pressure (subject to the gauge pressure behind the valve); After adjustment, lock the lock.

4. Lock the nut and open the back gate valve of the pressure reducing valve.

5. If the outlet pressure is higher than the set pressure, it must be readjusted from the first step, that is, it can only be adjusted from low pressure to high pressure.

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

AX46F pilot operated safety valvenext :

A47H steam safety valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported