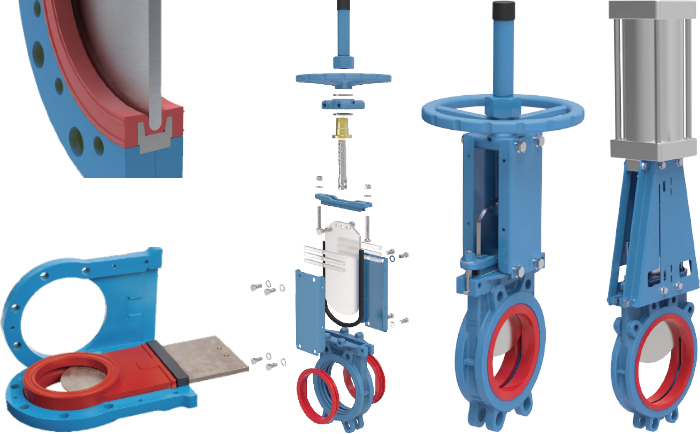

Pneumatic knife gate valve, also known as pneumatic knife gate valve, pneumatic knife gate gate valve, pneumatic slurry valve, and pneumatic mud valve, has a gate as its opening and closing component. The direction of movement of the gate is perpendicular to the direction of the fluid, and the medium is cut off by a blade shaped gate that can cut fiber materials. The gate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge shape, and the wedge angle varies with the valve parameters, usually 5 °, The gate plate of the wedge-shaped knife gate valve can be made into a whole, called a rigid gate plate; It can also be made into a gate that can produce slight deformation to improve its processability and compensate for the deviation of the sealing surface angle during the processing. This type of gate is called an elastic gate.

Item NO.:

XUVAL33-318Lead Time:

50 DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTMOQ:

10Pneumatic knife type gate valve

Manufacturing standards

Shell pressure: 1.5MPa, sealing pressure: 1.1 pressure, suitable temperature: 425 ℃, suitable medium: sewage, gas, pulp, etc.

Structural characteristics

1. The lifting type gate sealing surface can scrape off adhesive substances on the sealing surface and automatically clean debris.

2. Stainless steel gates can prevent seal leakage caused by corrosion.

3. The hard all gold sealing surface can ensure the sealing wear resistance and requirements.

4. The sealing surface of the valve body has no grooves, which do not produce any accumulation and can ensure flexible opening.

5. Short structural length can save raw materials, installation space, and effectively support pipeline strength.

6. The scientific design of the upper sealing packing box ensures the safety, effectiveness, and durability of the upper seal.

7. The triangular bracket saves raw materials and ensures the required mechanical properties.

8. The guide blocks on the valve body allow the gate to move correctly, and the four compression blocks ensure effective sealing of the gate.

9. The design of valve body reinforcement ribs improves the strength of the valve body.

10. The stainless steel valve stem is durable, and the double headed bolt makes the opening and closing more rapid.

11. Drive mechanism can be freely selected.

12. Over 150 caliber, using a fully enclosed structure, which can effectively open and prevent leakage.

13. The fluororubber sealing surface can achieve sealing effect and increase the operating temperature.

14. The rubber sealing surface is directly vulcanized inside the valve body and will not fall off.

technical parameter

In terms of performance

1. Valve control can be done locally and remotely, and can also achieve remote position display and remote centralized control according to user requirements.

2. Lightweight: The body is made of carbon steel or stainless steel, which reduces the weight by about 20% -30% compared to traditional gate valves, and is easy to install and maintain.

3. The use of this valve can improve the sealing performance of the conveying pipeline system, which will play a positive role in improving production efficiency and protecting the environment.

4. The sealing surface is made of high wear-resistant and corrosion-resistant ceramic materials, and embedded technology is used, which has high corrosion resistance and good wear resistance, thus making the valve have a long service life.

Installation instructions

1. Before installing the knife gate valve, the valve chamber and sealing surface must be inspected, and no dirt or sand particles are allowed to adhere to them;

2. All connecting bolts should be tightened evenly;

3. Check that the packing parts are tightly pressed to ensure both the sealing of the packing and the flexibility of the gate opening;

4. Before installing the valve, users must verify the valve model, connection size, and pay attention to the flow direction of the medium to ensure consistency with the valve requirements;

5. Users must reserve necessary space for valve drive when installing valves;

6. The wiring of the driving device must be carried out according to the circuit diagram;

7. Knife gate valves must be regularly maintained and must not be collided or squeezed arbitrarily to avoid affecting sealing.

Daily maintenance

1. Handwheels, handles, and transmission mechanisms are not allowed for lifting purposes, and collisions are strictly prohibited.

2. Double gate valves should be installed vertically (i.e. the valve stem is in a vertical position and the handwheel is at the top).

3. Gate valves with bypass valves should be opened before opening (to balance the pressure difference between the inlet and outlet and reduce the opening force).

4. Gate valves with transmission mechanisms should be installed according to the instructions in the product manual.

5. If the valve is frequently opened and used, lubricate it at least once a month

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported