Introduction to CS45H inverted bucket steam trap: The inverted bucket trap is based on the principle of phase change, relying on the different thermodynamic principles of the flow rate and volume change of steam and condensate when passing through, so that different pressure differences are generated up and down the valve plate to drive the valve plate to open and close the valve. Because the working power of thermodynamic traps comes from steam, the waste of steam is relatively large. The structure is simple, the water hammer is resistant, the maximum back is 50%, there is noise, the valve plate works frequently, and the service life is short. The inverted bucket trap has thermodynamic type (disc type), pulse type, orifice type.

Item NO.:

XUVAL77-61Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10CS45H inverted bucket steam trap

Product structure features of inverted bucket steam trap:

All moving parts in the inner cavity are made of stainless steel, which is resistant to wear and corrosion. Since steam cannot reach the valve seat hole sealed by water, there is no steam loss and high efficiency and energy saving. The floating bucket is inverted, it will not be damaged or crushed, it is not afraid of water hammer, and it has a long life.

The top of the inverted barrel is provided with a vent hole. The continuous air exhaust performance is good, and the cold hysteresis and air blockage will not be formed.

The inverted bucket steam trap is not affected by back pressure and can work well under high back pressure.

The inverted bucket steam trap does not work reliably. There are only two moving parts (the lever-and the inverted bucket), so there will be no jamming.

The valve seat and disc are on the top of the valve, and the disc can let dirt pass through during the switch. It has good self-cleaning performance and is free of dirt.

Working principle of inverted bucket steam trap:

The inverted bucket steam trap does not use the working principle of the density difference between condensate water and steam. The internal structure is connected to the inverted bucket by a lever system to overcome the steam pressure switch. The inside of the inverted bucket trap is an inverted bucket as a liquid level sensitive part. The bucket opens downwards. When the device is just started, air and low-temperature condensate appear in the pipeline. At this time, the trap is fully open, and the air and low-temperature condensate are quickly discharged, and the device quickly raises the temperature. When steam enters the inverted bucket, the inverted bucket generates upward buoyancy, and the inverted bucket is connected to the lever to drive the valve core to close the valve. There is a small hole in the inverted bucket, which can automatically exhaust air. When a part of the steam is discharged from the small hole, the other part of the steam produces condensate. The inverted bucket loses buoyancy and sinks. The inverted bucket is connected to the lever to drive the valve core to open the valve. When the steam enters the inverted bucket again, the valve is closed again, and the cycle works, intermittently draining water.

Steam trap model: CS45H (ER105)

Steam trap caliber: 15MM-200MM

Steam trap working pressure: 1.6MPA -4.0MPA

Steam trap connection method: flange connection

Steam trap operation mode: automatic

Steam trap use function: discharge the moisture in the steam

Steam trap using medium: steam、condensate

Steam trap: cast steel、stainless steel

Steam trap manufacturing standard: Ministry of Machinery standard or customized non-standard

Discontinuous drainage energy meter for inverted bucket steam trap (Kg/h):

881

881F

81

882

882F

82

883

883F

83

884

884F

84

815

815F

85

816

816F

Model

880

0.5

240

420

800

1520

2500

3960

7190

1

280

470

930

1750

2950

4500

8600

2

230

460

930

1800

3020

4500

8150

4

280

410

920

2000

3050

4400

8800

6

280

380

800

1560

2600

4600

8000

8

310

420

900

1750

2950

4900

8850

10

260

365

660

1550

2550

4500

8450

12

200

380

720

1730

2880

4850

9000

15

230

335

560

1500

2500

3000

8400

17

250

350

600

1550

2600

3200

8650

21

-

240

860

1200

2200

3400

7200

25

-

250

900

1300

2400

2900

7800

880-815 inverted bucket steam trap, without side inlet and side outlet, with filter screen, external dimensions (mm):

Model

Diameter

A

B

C

D

Maximum pressure kg/cm 2

880

1/2" 3/4"

96

76

70

128

25

881

1/2" 3/4" 1"

96

76

100

128

41

882

3/4" 1"

145

94

137

170

25

883

1" 1-1/4"

180

120

193

202

25

884

1-1/4" 1-1/2"

203

150

212

232

25

815

1-1/2" 2"

220

148

248

250

25

881F-886F inverted bucket steam trap, flange, attached filter, external dimensions (mm):

Model

Diameter

A

B

C

D

Maximum pressure kg/cm 2

881F

15、20、25

96

76

100

170

25

882F

20、25

145

94

137

210

41

883F

25、32

180

121

193

270

25

884F

32、40

203

150

212

320

25

815F

40、50

220

148

248

320

25

816F

65、80

265

489

310

400

25

81-86 Inverted Bucket Steam Traps with no lower inlet and upper outlet external dimensions (mm):

Model

Diameter

A

B

Maximum pressure kg/cm 2

81

1/2"

108

162

25

82

3/4" 1"

133

203

25

83

1"

162

273

25

84

1-1/4"

184

314

25

85

1-1/2"

216

380

25

86

2"

260

432

25

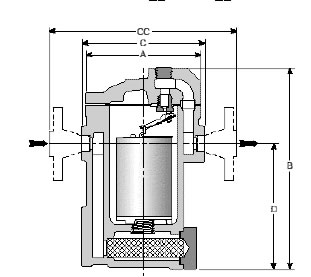

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported