Product introduction: ZXM new series pneumatic diaphragm sleeve control valve is a kind of pressure balance control valve. Equipped with multi spring actuator, the overall mechanism is compact, light weight and good stability. The fluid channel is s-streamline, with small pressure drop loss, large allowable pressure difference, low noise and large flow capacity.

Item NO.:

XUVAL77-33Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10ZXM pneumatic sleeve control valve

It is widely used to accurately control the process parameters of gas, fluid, steam and other media, such as pressure, flow, temperature, liquid level to keep at the given value. It is especially suitable for the occasions with large allowable flow, large pressure difference and low leakage requirement.

This series of products have many varieties, such as adjusting type, adjusting cut-off type, bellows sealing type, jacket insulation type, etc. The nominal pressure rating of the products are PN10, 16, 40 and 64; The diameter range of valve body is DN20 ~ 200. It is suitable for fluid temperature from - 200 ℃ to + 560 ℃. There are IV or VI leakage standards. The flow characteristics are linear or equal percentage. A variety of varieties and specifications are available.

Product features:

1.Adopt balanced valve core structure, small axial balance force, allowable pressure difference and good stability.

2.Strong interchangeability of sleeve, easy disassembly and repair.

3.The all metal valve core structure is suitable for various working situations, reaching the IV level leakage standard, ZXMO type soft seal structure valve core reaching the VI level leakage standard, ZXMP type soft seal structure valve core reaching the VI level leakage standard.

4.The valve body is designed as a constant cross-section low flow channel according to the principle of fluid mechanics, with a large adjustable range, an inherent adjustable ratio of 50, and a 30% increase in the rated flow coefficient.

5.The actuator adopts multi spring structure, which reduces the height by 30% and weight by 30%.

6.ZXPV bellows seal type control valve forms a complete seal to the moving valve stem, blocking fluid leakage.

7.ZXPJ type control valve is equipped with heat preservation jacket, which is used in the occasions where the fluid is easy to crystallize and solidify after cooling.

Material of main parts:

Valve body and cover: HT200, ZG230-450, ZG1Cr18Ni9Ti

Valve core and valve seat: 1Cr18Ni9Ti, Steller alloy surfacing

Soft sealing valve core: Reinforced Polytetrafluoroethylene

Filling: polytetrafluoroethylene, flexible graphite

Bellows: 1Cr18Ni9Ti

Filling sheet: Rubber asbestos board, 10 #, 1Cr18Ni9Ti asbestos spiral wound gasket

Membrane cover: A3

Corrugated diaphragm: NBR clip reinforced polyester fabric

Spring: 60simn

Valve stem and push rod: 2Cr13, 1Cr18Ni9Ti

Bushing: 2Cr13

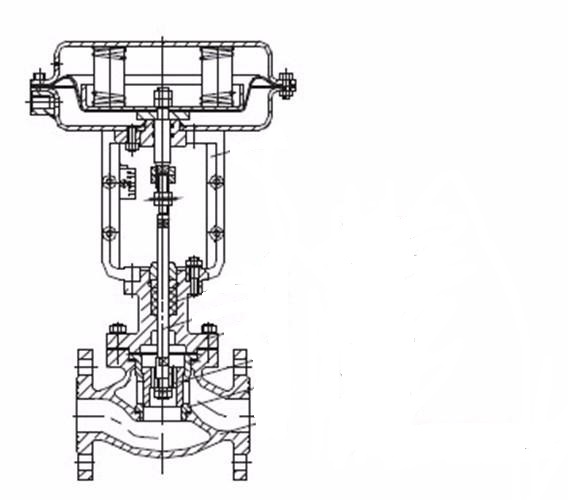

Product structure chart:

Specifications and technical parameters:

Nominal diameter DN (mm)

20

25

32

40

50

65

80

100

125

150

200

Straight line

6.9

11

17.4

27.5

44

69

110

176

275

400

690

Equal percentage

6.3

10

16

25

40

63

100

160

250

400

630

Rated stroke L (mm)

16

25

40

60

Effective area of diaphragm AE (cm2)

280

400

600

1000

Signal range pr (kPa)

20~100、40~200

Gas source pressure PS (MPA)

0.14~0.4

Inherent flow characteristics

Straight line, equal percentage

Inherent adjustable ratio

50

Allowable leakage

Hard seat unbalanced type: Class IV (10-4 valve rated capacity) soft seat: class VI

Nominal pressure PN (MPA)

1.0、1.6、4.0、6.4

Working temperature T (℃)

Normal temperature type

-20~200、-40~240、-60~250

Heat dissipation type

-40~450、-60~450

High temperature type

300~560

Low temperature type

-60~100、-100~-200、-200~-250

Allowable differential pressure gauge of air closing control valve unit: MPa

Rubber area AE (cm2) of diaphragm

280

400

600

1000

Signal range pr (kPa)

20-100

20-100

40-200

20-100

20-100

40-200

20-100

20-100

40-200

20-100

20-100

40-200

Gas source pressure PS (MPA)

0.14

0.14

0.25

0.14

0.14

0.25

0.14

0.14

0.25

0.14

0.14

0.25

Accessories required

-

P

P

-

P

P

-

P

P

-

P

P

20

10

2.67

6.23

6.40

25

12

2.22

5.19

6.40

32

15

2.58

6.02

6.40

40

20

3.18

6.40

6.40

25

2.58

6.02

6.40

2.12

4.95

6.37

50

25

2.58

6.02

6.40

32

2.12

4.95

6.37

40

1.73

4.05

5.21

65

32

2.04

4.77

6.14

80

40

2.60

6.08

6.40

50

2.05

4.77

6.14

65

1.68

3.93

5.06

100

50

2.05

4.77

6.14

65

1.69

3.39

5.06

70

1.36

3.18

4.09

125

65

1.83

4.28

5.51

150

70

2.27

5.30

6.40

100

1.84

4.28

5.51

125

1.54

3.59

4.62

200

100

1.84

4.28

5.51

125

1.54

3.59

4.62

150

1.12

2.62

3.37

Allowable differential pressure gauge of air open control valve unit: MPa

Film adhesive area AE (cm2)

28

400

600

1000

Signal range pr (kPa)

20-100

20-100

20-100

20-100

20-100

20-100

20-100

20-100

Gas source pressure PS (MPA)

0.14

0.14

0.14

0.14

0.14

0.14

0.14

0.14

Accessories required

-

P

-

P

-

P

-

P

20

10

2.67

6.23

25

12

2.22

5.19

32

15

2.58

6.02

40

20

3.18

6.40

25

2.58

6.02

2.12

4.95

50

25

2.58

6.02

32

2.12

4.95

40

1.73

4.05

65

32

2.04

4.77

80

40

2.60

6.08

50

2.05

4.77

65

1.68

3.93

100

50

2.05

4.77

65

1.69

3.39

70

1.36

3.18

125

65

1.83

4.28

150

70

2.27

5.30

100

1.84

4.28

125

1.54

3.59

200

100

1.84

4.28

125

1.54

3.59

150

1.12

2.62

**For zxpv single seat corrugated tube seal regulating valve, the maximum allowable differential pressure is 1.0MPa. If the value in the table is less than 1.0MPa, it will not change. If the value is less than 1.0MPa, it will take 1.0MPa.

The relative flow value under different inherent flow characteristics and different relative stroke: R50

[UNK]Q/Qmax/i/l%

0

10

20

30

40

50

60

70

80

90

100

Straight line

2

11.8

21.6

31.4

41.2

51

60.8

70.6

80.4

90.2

100

Equal ratio

2

3

4.37

6.5

9.6

14.1

20.9

30.9

45.7

67.6

100

Quick open

2

31.6

44.8

54.8

63.2

70.7

77.5

83.6

89.4

94.8

100

Parabola

2

5

9.8

15.9

23.5

32.6

43.1

55.1

68.6

58.5

1001

Size and weight

Dimension table of standard type, heat dissipation type and high temperature type unit: mm

Nominal diameter

20

25

32

40

50

65

80

100

125

150

200

282

308

394

494

L

PN16,40

150

160

180

200

230

290

310

350

400

480

600

PN64

230

230

260

260

300

340

380

430

500

550

650

H1

PN16

52.5

57.5

70

75

82.5

92.5

100

110

125

143

170

PN40

52.5

57.5

70

75

82.5

92.5

100

117.5

135

150

187.5

PN64

65

70

78

85

90

102.5

107.5

125

147.5

172.5

207.5

H

Standard type

PN16

429

438

474

476

502

622

646

687

835

889

981

PN40

429

438

474

476

502

622

646

695

845

896

1000

PN64

456

468

511

525

535

663

673

705

868

958

1260

Heat dissipation high temperature type

570

570

610

610

630

730

810

820

960

1090

1180

**The height H1 and H of jacket increased by 15%

|

Nominal diameter |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| A |

282 |

308 |

394 |

494 |

|||||||

| L | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 |

| H1 | 52.5 | 57.5 | 70 | 75 | 82.5 | 92.5 | 100 | 117.5 | 135 | 150 | 187.5 |

|

H bellows type |

499 | 511 | 560 | 617 | 620 | 710 | 767 | 792.5 | 807 | 1057.5 | 1087.5 |

|

Nominal diameter |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|

|

| A |

282 |

308 |

394 |

494 |

|

|

|||||||

| L | PN16,PN40 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 |

|

| PN64 | 230 | 230 | 260 | 260 | 300 | 340 | 380 | 430 | 500 | 550 | 650 |

|

|

| H1 | PN16.PN40 | 52.5 | 57.5 | 70 | 75 | 82.5 | 92.5 | 100 | 117.5 | 135 | 150 | 187.5 |

|

| PN64 | 65 | 70 | 77.5 | 85 | 900 | 102.5 | 107.5 | 125 | 147.5 | 172.5 | 207.5 |

|

|

| H2 | -60~-100℃ | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 700 | 700 | 700 |

|

| -100~-200℃ | 700 | 700 | 700 | 700 | 700 | 800 | 800 | 800 | 900 | 900 | 900 |

|

|

| -200~-250℃ | 900 | 900 | 900 | 900 | 900 | 1000 | 1000 | 1000 | 1100 | 1100 | 1100 |

|

|

| H | -60~-100(℃) | PN16.PN40 | 862.5 | 865 | 902 | 907 | 914.5 | 1118.5 | 1126 | 1141.5 | 1135 | 1348 | 1385.5 |

| PN64 | 875 | 874 | 909.5 | 917 | 922 | 1128.5 | 1133.5 | 1149 | 1347.5 | 1370.5 | 1405.5 | ||

| -100~-200(℃) | PN16,PN40 | 1062.5 | 1075 | 1102 | 1107 | 1114.5 | 1318.5 | 1326 | 1349 | 1547.5 | 1570.5 | 1605.5 | |

| PN64 | 1075 | 1080 | 1109.5 | 1117 | 1122 | 1328.5 | 1333.5 | 1349 | 1547.5 | 1570.5 | 1605.5 | ||

| -200~-250(℃) | PN16,PN40 | 1262.5 | 1267.5 | 1302 | 1307 | 1314.5 | 1518.5 | 1526 | 1541.5 | 1735 | 1748 | 1785.5 | |

| PN64 | 1275 | 1280 | 1309.5 | 1317 | 1322 | 1528.5 | 1533.5 | 1549 | 1747.5 | 1770.5 | 1805.5 | ||

|

|

D3 | 260 | 260 | 285 | 305 | 340 | 370 | 405 | 460 | 525 | 590 | 700 | |

|

|

D4 | 290 | 290 | 315 | 335 | 370 | 400 | 435 | 490 | 555 | 630 | 740 | |

|

|

Bolt hole N(number) - D (diameter) |

8-14 | 8-14 | 8-14 | 8-16 | 8-16 | 10-16 | 10-16 | 12-18 | 14-18 | 16-18 | 18-18 |

|

Weight table of control valve unit: kg

|

Nominal diameter |

20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|

|

Standard type |

PN16 | 16 | 17 | 19 | 21 | 23 | 35 | 48 | 57 | 64 | 70 | 900 |

| PN40 | 16 | 17 | 19 | 21 | 23 | 35 | 48 | 60 | 67 | 74 | 95 | |

| PN64 | 20 | 21 | 25 | 30 | 33 | 44 | 71 | 91 | 100 | 115 | 145 | |

|

Heat dissipation high temperature type |

17 | 18 | 20 | 22 | 25 | 36 | 51 | 60 | 67 | 74 | 95 |

|

|

Bellows type |

20 | 21 | 25 | 30 | 33 | 48 | 71 | 91 | 102 | 115 | 145 |

|

|

Low temperature type |

20 | 21 | 23 | 26 | 28 | 42 | 58 | 69 | 77 | 84 | 108 |

|

*The weight of heat dissipation high temperature type in this table is based on PN16, and that of low temperature type is based on PN40

Connection standard:

Flange standard: cast iron flange according to JB78-59

Cast steel flange according to GB9113-88 JB/T79.1-94

Flange sealing surface type: PN10, PN16 are convex surface; PN40 and PN64 are concave and convex, and the valve body is concave.

The structure length is in accordance with the standard of GB12221-89

Diaphragm actuator gas signal interface: internal thread M16 × one point five

Jacket heat carrier interface: butt welding φ eighteen × four

*Valve body flange and flange end face distance can be manufactured according to user specified standards, such as ANSI, JIS, JPI and other standards

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

KC8107Q pneumatic diaphragm low temperature control valvenext :

ZXN pneumatic double seat control valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported