Product introduction: ZQDF(Y) series steam (liquid) solenoid valve is an actuator used in industrial process automation control system. It can automatically open or close the valve after receiving the electric control signal to realize the on-off or flow adjustment control of the fluid medium in the pipeline. , So as to automatically adjust or remotely control the temperature, flow, pressure and other parameters in the system. ZQDF series steam solenoid valves can be widely used in production and scientific research departments such as textiles, printing and dyeing, chemicals, plastics, rubber, pharmaceuticals, food, building materials, machinery, electrical appliances, and surface treatment, as well as in people's daily life facilities such as bathrooms, canteens, and air conditioners.

Item NO.:

XUVAL77-103Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SliveryMOQ:

10ZQDF explosion-proof solenoid valve

ZQDF series solenoid valve is mainly used for the control of air, steam, coal gas and other gaseous media; ZQDF-Y series solenoid valve is mainly used for tap water, distilled water, frozen brine, electroplating waste liquid and other liquid media, and also used for viscosity less than 4°E Oils.

Model specification description:

Model

ZQDF-1

ZQDF-2

ZQDF-3

ZQDF-1Y

ZQDF-2Y

ZQDF-3Y

Nominal pressure Mpa

1.6

Working pressure difference Mpa

DN15~50

0~1.6

DN65~100

0.05~1.6

Type of medium

Gas, air, etc.

Saturated Vapor

Superheated steam or high temperature gas

Water, oil and liquid

Hot water, oil

Oil

Medium temperature ℃

≤60

≤180

≤220

≤60

≤180

≤220

Voltage

Other specifications of AC220V can be made for special order

Service life

According to JB/T7352-94

Leakage m1/min

According to JB/T7352-94*F

Power consumption

AC≤70VA DC≤60W

Technical parameter:

Nominal diameter DN

Dimensions

Internal thread

Dimensions

Flange connection

H

L

G

H

L

D

D1

D2

b

f

N-∅d

15

148

92

1/2

176

130

95

65

46

14

2

4-14

20

148

92

3/4

181

150

105

75

56

16

2

4-14

25

148

110

1

210

160

115

85

65

16

3

4-14

32

182

120

1-1/4

221

180

140

100

76

18

3

4-18

40

182

140

1-1/2

230

200

150

110

84

18

3

4-18

50

192

162

2

252

230

165

125

99

20

3

4-18

65

265

290

185

145

118

20

3

4-18

80

276

310

200

160

132

20

3

8-18

100

373

350

220

180

156

22

3

8-18

Installation instructions:

1. When installing, the solenoid valve coil should be upward and keep the vertical position. The arrow or mark on the solenoid valve should be consistent with the flow direction of the pipeline. It should not be installed where there is water splashing or water leakage.

2. The working medium of the solenoid valve should be clean and free of particulate impurities. The dirt and filter on the surface of the solenoid valve internals must be cleaned regularly.

3. When the solenoid valve fails, in order to isolate the solenoid valve in time and ensure the normal operation of the system, install a bypass device. Note: The valve on the bypass must be closed at ordinary times. If the solenoid valve is installed on the bracket, the diameter of the solenoid valve should be smaller than that of the valve on the main pipeline.

4. Before installing the solenoid valve, the pipeline must be cleaned. It is recommended to install a filter in front of the valve and install a trap in the steam pipeline.

5. Do not install the valve in the recessed part of the pipeline, so as not to hinder the action due to the precipitation of steam, condensate, impurities, etc. in the valve.

6. Ordinary type cannot be used in explosion hazard situations.

7. In the case of insufficient pipe rigidity, it is recommended to fix the pipes before and after the valve with brackets to prevent vibration caused by the solenoid valve during operation.

8. Before installation, pay attention to read the product label, carefully read the instruction manual, and judge whether the product meets the conditions of use.

9. Pressure gauges should be installed on the pipes before and after the solenoid valve to observe the pipe pressure.

Use and maintenance:

1. It is recommended that the user unit appoint a person to be responsible for use and maintenance.

2. After the solenoid valve is installed, it must be tested for several times with the medium, and then it can be put into formal use after confirming that it is normal.

3. The dirt on the inside and outside of the large valve and the suction surface of the armature should be cleaned regularly. Be careful not to damage the sealing surface.

4. When the solenoid valve is not used for a long time, the manual valve in front of the valve should be closed. When it is reactivated, the steam solenoid valve should drain the condensed water and make a trial operation several times. It can be put into use after the switch is normal.

5. When the solenoid valve is removed from the pipeline and not in use, the internal parts should be tested clean and blown with compressed air for storage.

6. When using for a long time, if the seal between the piston and the valve seat is not good, the sealing surface of the piston can be ground again, and then ground with the valve seat.

7. When working, pay attention to the pressure gauges before and after the valve. The working pressure must not exceed the rated pressure, and the working pressure difference must be within the range of the rated pressure difference. When the working pressure exceeds the rated pressure or the working pressure difference exceeds the rated pressure difference, the solenoid valve should be stopped and the front and rear manual valves should be closed to prevent the solenoid valve from exploding and leaking.

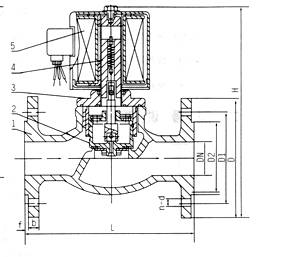

Outline structure drawing:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Electric temperature control valvenext :

ZQDF steam solenoid valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported