Product introduction: Z941 electric heat transfer oil special gate valve is widely used in petrochemical, thermal power plants and other oil and steam pipelines as opening and closing devices to connect or cut off the medium in the pipeline.

Item NO.:

XUVAL77-117Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10Z941 special gate valve for electric heat transfer oil

Electric, flange connection, rising rod wedge type rigid single gate, the sealing surface of the valve seat is made of alloy steel (Z941H-16C~63 Z941Y-16C~63 Z941Y-16P~63P Z941Y-16R~63R Z941Y-16I~63I) , Chromium-nickel-titanium stainless steel (Z941W-16P~63P), chromium-nickel-molybdenum titanium stainless steel (Z941W-16R~63R), chromium-molybdenum steel (Z941W-16I~63I), nominal pressure PN16~PN63, valve body material is carbon steel (Z941H-16C~63 Z941Y-16C~63), chromium nickel titanium stainless steel (Z941Y-16P~63P Z941W-16P~63P), chromium nickel molybdenum titanium stainless steel (Z941Y-16R~63R Z941W-16R~63R), chromium molybdenum Gate valve of alloy steel (Z941Y-16I~63I Z941W-16I~63I).

Main features and uses:

1. The structure is compact, the design is reasonable, the valve rigidity is good, the passage is smooth, and the flow resistance coefficient is small.

2. The sealing surface is made of stainless steel and hard alloy, which has a long service life.

3. Using flexible graphite packing, reliable sealing, light and flexible operation.

4. The driving mode is divided into manual, electric, pneumatic, gear transmission power, structure type: elastic wedge single ram, rigid wedge single ram and double ram.

5. It is widely used in petrochemical, thermal power plants and other oil and steam pipelines as opening and closing devices for connecting or cutting off the medium in the pipeline.

The main performance parameters of the product:

|

Model |

PN |

Working pressure/MPa |

Applicable temperature/℃ |

Applicable medium |

| Z941H-16C~63 |

16~63 |

1.6~6.3 |

≤425 |

Water, steam, oil |

| Z941Y-16C~63 | ||||

| Z941Y-16P~63P | ≤150 |

Weakly corrosive medium |

||

| Z941Y-16R~63R | ||||

| Z941Y-16I~63I | ≤550 |

Steam, oil |

||

| Z941Y-16P~63P | ≤150 |

Weakly corrosive medium |

||

| Z941W-16R~63R | ≤200 |

Acetic acid |

||

| Z941W-16I~63I | ≤550 |

Oil, steam |

||

| Z941W-16P~63P | ≤150 |

Weakly corrosive medium |

| Model |

Material |

|||

|

Body, bonnet, gate |

Stem |

Sealing surface |

Filler |

|

| Z941H-16C~63 |

Carbon steel |

Chrome stainless steel |

Surfacing iron-based alloy |

Asbestos graphite or flexible graphite |

| Z941Y-16C~63 |

Hardfacing hard alloy |

|||

| Z941Y-16P~63P |

Chromium nickel titanium stainless steel |

Chromium nickel titanium stainless steel |

Hardfacing hard alloy |

PTFE |

| Z941Y-16R~63R |

Chromium nickel molybdenum titanium stainless steel |

Chromium nickel molybdenum titanium stainless steel |

||

| Z941Y-16I~63I |

Chrome Molybdenum Alloy Steel |

Hardfacing hard alloy |

||

| Z941Y-16P~63P |

Chromium nickel titanium stainless steel |

PTFE |

||

| Z941W-16R~63R |

Chromium nickel molybdenum titanium stainless steel |

Ontology |

Asbestos graphite or flexible graphite |

|

| Z941W-16I~63I |

Chrome-molybdenum steel |

Heat-resistant steel or stainless steel |

||

| Z941W-16P~63P |

Chromium nickel titanium stainless steel |

|||

|

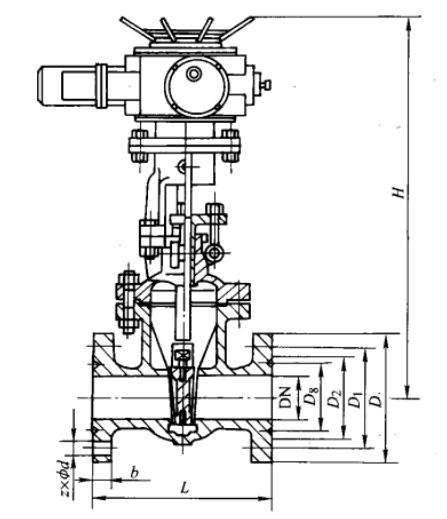

Nominal diameter DN (mm) |

L | D | D1 | D2 | b | f | Z-∅d | H |

Electric device model |

|

Z940 Z941 H-16C Z940 W Z940 W Z940 H Z941 H-16P Z941 H-16R Z941 Y-16I Z942 Y-16C Z942 Y Z942 Y Z942 |

|||||||||

| 40 | 200 | 145 | 110 | 85 | 16 | 3 | 4-18 | 595 | ZB15 |

| 50 | 250 | 160 | 125 | 100 | 16 | 3 | 4-18 | 653 | ZB15 |

| 65 | 265 | 180 | 145 | 120 | 18 | 3 | 4-18 | 665 | ZB15 |

| 80 | 280 | 195 | 160 | 135 | 20 | 3 | 8-18 | 725 | ZB15 |

| 100 | 300 | 215 | 180 | 155 | 20 | 3 | 8-18 | 787 | ZB15 |

| 125 | 325 | 245 | 210 | 185 | 22 | 3 | 8-18 | 806 | ZB20 |

| 150 | 350 | 280 | 240 | 210 | 24 | 3 | 8-23 | 955 | ZB20 |

| 200 | 400 | 335 | 295 | 265 | 26 | 3 | 12-23 | 1105 | ZB40 |

| 250 | 450 | 405 | 355 | 320 | 30 | 3 | 12-25 | 1343 | ZB40 |

| 300 | 500 | 460 | 410 | 375 | 30 | 4 | 12-25 | 1516 | ZC45 |

| 350 | 550 | 520 | 470 | 435 | 34 | 4 | 16-25 | 1678 | ZC45 |

| 400 | 600 | 580 | 525 | 485 | 36 | 4 | 16-30 | 1849 | ZC90 |

| 450 | 650 | 640 | 585 | 545 | 40 | 4 | 20-30 | 1937 | ZC90 |

| 500 | 700 | 705 | 650 | 608 | 44 | 4 | 20-34 | 2234 | ZC120 |

| 600 | 800 | 840 | 770 | 718 | 48 | 5 | 20-41 | 2432 | ZC180 |

| 700 | 900 | 910 | 840 | 788 | 50 | 5 | 24-41 | 2489 | ZC250 |

| 800 | 1000 | 1020 | 950 | 898 | 52 | 5 | 24-41 | 2643 | ZC350 |

| 900 | 1100 | 1120 | 1050 | 998 | 54 | 5 | 28-41 | 2945 | ZC500 |

| 1000 | 1200 | 1255 | 1170 | 1110 | 56 | 5 | 28-48 | 3083 | ZC500 |

| 1200 | 1350 | 1485 | 1390 | 1325 | 58 | 5 | 32-54 | 3382 | ZC800 |

| 1400 | 1500 | 1685 | 1590 | 1525 | 60 | 5 | 36-54 | 3718 | ZC1000 |

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Z960Y high temperature and high pressure gate valvenext :

PZ773HX-10C cast steel hydraulic movable knife gate valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported