Overview of NKJ61H vacuum globe valve: The main body of this series of valves adopts casting and forging structure, with parallel double sealing pairs and semi-forced two-way sealing. The sealing surface moves in place and the wedge block moves step by step to achieve zero leakage. The sealing surface has low friction, easy opening and closing, and automatic compensation for the wear of the sealing surface.

Item NO.:

XUVAL77-86Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10Welded vacuum globe valve

The structure is simple, compact, convenient for maintenance and long service life. The valve cover packing chamber is equipped with a vacuum sealing structure, which has a self-expanding compression effect, and the seal is sealed with a high-strength expansion material, so that the system is completely isolated from the atmosphere and has a good system air tightness. This series of valve connection forms are divided into flange and welding, and the driving methods are manual and electric.

The valve is suitable for pipelines whose working temperature is ≤425℃ and ≤550℃, and the working medium is water, steam or air, as an opening and closing device; it is especially suitable for steam turbine condensation and vacuum negative pressure systems in thermal power plants, and plays a role of vacuum isolation and sealing.

Vacuum globe valve model: NKJ61H

Vacuum golbe valve Nominal diameter: 15MM-400MM

Working pressure of vacuum globe valve: 1.6MPa -6.4MPa

Vacuum globe valve connection method: welding connection

Vacuum globe valve form: manual

Vacuum globe valve Main function: as a switch

Vacuum golbe valve Use medium: corrosion-resistant medium

Vacuum globe valve Material: WCB standard carbon steel stainless steel

Vacuum globe valve standard: Ministry of Machinery standard or customized non-standard

NKJ61H vacuum globe valve valve structure type:

Product type

Shell strength test/MPa

Upper sealing test/MPa

Seal test/MPa

Applicable medium

Applicable temperature/℃

NKJ61H-40

6.0

4.4

4.4

Water, steam, air

≤425

NKJ61H-64

96

7.0

7.0

NKJ61H-100

15.0

11.0

11.0

NKJ61Y-40I

6.0

4.4

4.4

Water, steam, air

≤550

NKJ61Y-64I

9.6

7.0

7.0

NKJ61Y-100I

15.0

11.0

11.0

Material of main parts of NKJ61H vacuum globe valve:

Part name

Body Bonnet

Stem

Disc

Sealing surface

Stem nut

Filler

Fastener

NKJ61H-C type

25 or WCB

Chrome stainless steel

Chrome stainless steel

H: Alloy steel

Aluminum bronze

Expanded composite stone

High quality carbon steel

NKJ61Y-l type

Chromium molybdenum steel

20CrlM01vA or 38CrMoAlA

12CrlMo 1VA

Y: Cemented carbide

Chromium molybdenum steel

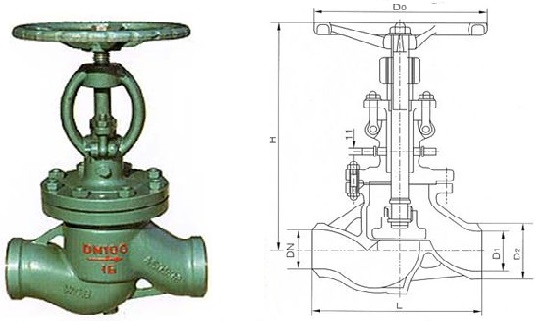

NKJ61H vacuum globe valve main dimensions:

Main external dimensions and connection dimensions/mm

L

H

D

D0

D1

L1

☌

W

10

4.0

130

245

36

11

18.4

10

-

120

15

130

245

36

16

22.5

10

-

120

20

150

265

44

21

28.5

11

-

160

25

160

270

48

26

34.5

12

-

200

32

180

285

48

34

-

-

37o30'

200

40

200

320

55

40

-

-

37o30'

240

50

230

365

64

48

-

-

37o30'

320

65

290

410

82

66

-

-

37o30'

300

80

310

430

95

78

-

-

37o30'

300

100

350

470

117

100

-

-

37o30'

350

125

400

500

143

126

-

-

37o30'

350

150

480

533

167

150

-

-

37o30'

400

10

6.4

130

245

36

10

18.4

10

-

120

15

130

245

36

15

22.5

10

-

120

20

150

265

44

20

28.5

11

-

160

25

160

270

48

25

34.5

12

-

200

32

180

280

48

33

-

-

37o30'

200

40

200

320

55

39

-

-

37o30'

240

50

230

365

64

48

-

-

37o30'

320

65

290

410

82

65

-

-

37o30'

320

80

310

430

95

76

-

-

37o30'

360

100

350

470

117

98

-

-

37o30'

400

125

480

500

143

123

-

-

37o30'

400

150

480

533

167

148

-

-

37o30'

500

10

10.0

130

245

36

10

18.4

10

-

120

15

130

245

36

14

22.5

10

-

120

20

150

265

44

20

28.5

11

-

160

25

160

270

48

25

34.5

12

-

200

32

180

285

48

32

-

-

37o30'

200

40

200

320

55

38

-

-

37o30'

240

50

230

355

64

48

-

-

37o30'

320

65

290

410

82

63

-

-

37o30'

320

80

310

430

95

74

-

-

37o30'

360

100

350

470

117

97

-

-

37o30'

400

125

400

500

143

123

-

-

37o30'

400

150

480

533

167

148

-

-

37o30'

500

Product structure diagram:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

J41B Ammonia Globe Valvenext :

J11Y/J61Y forged steel globe valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported