TP41Y valve sleeve type blowdown valve product overview: TP41Y valve sleeve type blowdown valve is a sleeve type blowdown valve composed of valve body, valve seat, valve core, valve sleeve and valve stem, etc., used for oil and gas or gas medium transportation pipelines to cut off the blowdown. It mainly passes through the valve core. The up and down operation changes the valve opening. When the valve is opened, the valve core is slowly opened.

Item NO.:

XUVAL77-112Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10TP41Y valve sleeve drain valve

When the valve core sealing surface and the valve seat sealing surface are spaced apart, the gas and impurities pass through the throttle shaft, sleeve window, and valve sleeve window. After the flow, it is discharged from the drain window of the valve sleeve. The end face of the PTFE embedded in the inner cavity of the valve core is pressed tightly on the end face of the valve seat to form a soft seal; The soft dual seal pair meets the zero leakage requirements under the working conditions of high pressure and other media.

Advantages of TP41Y valve sleeve blowdown valve:

TP41Y valve sleeve type blowdown valve spool seal pair and valve seat seal pair both use medium pressure to realize self-cleaning function when opening and closing the discharge and closing to meet the requirements of the discharge conditions. The valve is designed with seat nozzles and throttling inside the valve. The shaft, valve sleeve orifice and sleeve window play a variety of throttling and pressure relief effects on the medium flowing through the valve during sewage discharge, which is conducive to the safe operation of the pipeline sewage device and on-site operation control. The valve core is provided with two O-rings, and a slag storage tank is arranged between the two O-rings, so that the valve core can automatically remove slag when the valve core moves up and down in the inner cavity of the valve sleeve.

TP41Y valve sleeve type blowdown valve parts material table:

Serial number

Part Name

Material name

1

Body

WCB

CF8

CF3

CF8M

CF3M

2

Bonnet

WCB

CF8

CF3

CF8M

CF3M

3

Stem

2Cr13

304

304L

316

316L

4

Stem nut

Aluminum bronze

Aluminum bronze

Aluminum bronze

Aluminum bronze

Aluminum bronze

5

Disc

2Cr13+ cemented carbide

304+ cemented carbide

304L+ cemented carbide

316+ cemented carbide

316L+ cemented carbide

6

Seat

2Cr13+ cemented carbide

304+ cemented carbide

304L+ cemented carbide

316+ cemented carbide

316L+ cemented carbide

7

Valve sleeve

304

304

304L

316

316L

8

Sealing ring

PTFE

PTFE

PTFE

PTFE

PTFE

9

Filler

PTFE expanded graphite

PTFE expanded graphite

PTFE expanded graphite

PTFE expanded graphite

PTFE expanded graphite

TP41Y valve sleeve type blowdown valve technical specification table:

Nominal pressure PN (MPa)

1.6

2.5

4.0

6.4

10.0

Shell test pressure (MPa)

2.4

3.75

6.0

9.6

15.0

High pressure liquid sealing test pressure (MPa)

1.76

2.75

4.4

7.04

11.0

Low pressure gas seal test pressure (MPa)

0.6

0.6

0.6

0.6

0.6

Design and manufacture

GB/T26145-2010 blowdown valve

Structure length

GB/T26145-2010 blowdown valve

Flange size

JB/T79-2015, GB/T9113-2010, HG/T20592-2009, ANSI

Inspection test

GB/T 13927-2008 Industrial Valve Pressure Test

Applicable medium

Basic type: oil, natural gas, water, etc.; sulfur-resistant type: medium containing H2S and CO2>500Mg/m

TP41Y valve sleeve type blowdown valve outline dimension table:

Nominal pressure PN (MPa)

Nominal diameter DN(mm)

Size (mm)

Weight (KG)

L

H

H1

D0

1.6

25

216

243

86

180

18

40

230

265

108

250

25

50

230

346

115

250

28

80

310

409

146

300

53

100

350

433

163

300

62

150

480

521

202

350

128

200

600

594

292

350

168

250

730

621

355

400

289

2.5

25

216

243

86

180

18

40

230

265

108

250

25

50

230

346

115

250

28

80

310

409

146

300

57

100

350

433

163

300

69

150

480

521

202

350

145

200

600

594

292

350

188

250

730

621

355

400

315

4.0

25

216

243

86

180

21

40

230

265

108

250

31

50

230

346

115

250

35

80

310

409

146

300

70

100

350

433

163

300

85

150

480

521

202

350

172

200

600

594

292

350

219

250

730

621

355

400

378

6.4

25

216

243

86

180

21

40

230

265

108

250

37

50

230

346

115

250

42

80

310

409

146

300

84

100

350

433

163

300

100

150

480

521

202

350

208

200

600

594

292

350

265

250

730

621

355

400

452

10.

25

230

245

78

200

30

40

260

265

106

250

44

50

300

287

110

300

58

80

380

409

152

350

98

100

430

433

169

350

98

150

559

531

225

400

245

200

660

709

321

500

316

250

787

817

399

500

540

16.0

25

230

215

78

200

36

40

260

265

105

250

54

50

300

237

110

300

69

80

390

414

155

350

120

100

450

440

175

350

150

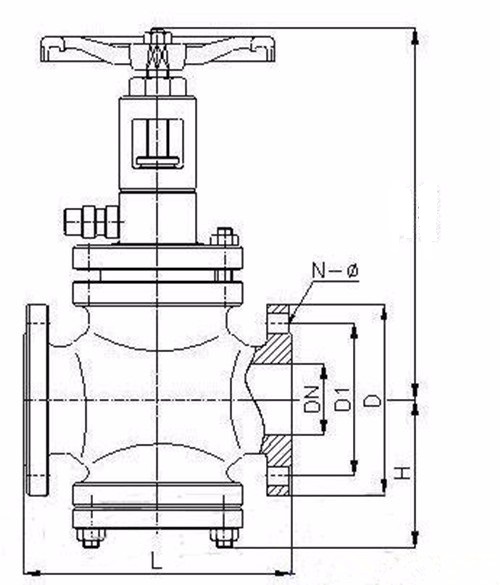

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Automatic exhaust valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported