Valve application: Q641 pneumatic ball valve series products have compact structure, reliable sealing and convenient maintenance. The sealing surface and spherical surface are often closed, which are not easy to be eroded by media. They are easy to operate and maintain. They are suitable for general working media such as water, solvent, acid and natural gas, and also suitable for media with poor working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. They are widely used in various industries the application of.

Item NO.:

XUVAL77-10Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

silveryMOQ:

10

Q641 pneumatic ball valve

Valve application:

Q641 pneumatic ball valve series products have compact structure, reliable sealing and convenient maintenance. The sealing surface and spherical surface are often closed, which are not easy to be eroded by media. They are easy to operate and maintain. They are suitable for general working media such as water, solvent, acid and natural gas, and also suitable for media with poor working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. They are widely used in various industries the application of.

Common models:

Common models of pneumatic ball valve are: Q641F, Q641H, Q641Y, Q661F, Q644F, Q647H, Q647F, Q647Y, Q645F, QD647F, VQ647H, PQ640H, PQ640Y, PY640F, PQ671H, etc.

Valve features:

1. When the full diameter ball valve is opened, the ball channel, valve channel and connecting pipe diameter are equal and form a diameter, and the medium can flow through almost without loss.

2. The pneumatic ball valve can be fully closed and fully opened by rotating 90 ° and can be opened and closed quickly. Compared with gate valve and globe valve of the same specification, the ball valve is small in volume and light in weight, which is convenient for pipeline installation.

3. Advanced valve seat: the valve seat is designed based on many years of ball valve manufacturing experience to ensure valve sealing, low friction coefficient, small operating torque, a variety of valve seat materials and wide application range.

4. Correct switch handle: flat head valve stem is adopted, and the connection with the handle will not be misplaced, so as to ensure that the switch state indicated by the handle is consistent with that of the valve.

.5. Locking device: in order to prevent the valve switch from misoperation, there are locking holes at the fully open and fully closed positions of the valve to ensure that the valve is in the correct position.

6. Anti flying structure of valve stem: the valve stem is bottom mounted to prevent it from flying out under pressure. At the same time, it can form metal contact with the valve body after fire to ensure the sealing of valve stem.

7. Pneumatic ball valve uses a ball with a circular through hole as the opening and closing part. Driven by the valve stem, the ball rotates 0 ~ 90 degrees around the center of the valve stem to complete the opening and closing function. It has the characteristics of compact structure and rapid opening and closing. By rotating 90 degrees, the valve can be closed and the medium in the pipeline can be cut off. The valve stem is bottom mounted, which prevents the accident of the valve stem from penetrating and ensures the safety of use.

8. Changing the material of valve body, ball and seal can be applied to various working conditions. The valve body of ball valve can be integral or combined.

Executive standard:

Design specification: GB / t12237 API 6D API 608 BS 5351

Structure length: GB / T 12221 ASME B16.10

Flange connection: GB / T 9113 ASME B16.5

Test and inspection: GB / T 13927 API 598 API 6D

Performance parameters:

working pressure(MPa)

1.6~6.3 (Calss150-Calss400)

caliber(mm)

DN15-DN200 1/2″-8″

Applicable medium

Water, oil, gas, acetic acid, nitric acid and other media

Material

valve body

WCB CF8 CF8 Cr Mo steel low temperature steel nickel alloy

sphere

WCB CF8 CF8 Cr Mo steel low temperature steel nickel alloy

Stem

2Cr13 F304 F316 chromium molybdenum steel low temperature steel nickel alloy

Sealing surface

PTFE peek stainless steel Stellite tungsten nickel carbide alloy

filler

Flexible graphite PTFE

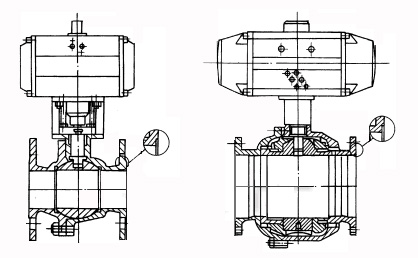

Schematic:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Q47H/Y Q347H/Y/F Q647H/Y Q947H/Y hard seal fixed ball valvenext :

Q647 pneumatic fixed ball valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported