Overview of nitrogen sealing device: The nitrogen sealing device is mainly used for the constant control of the nitrogen pressure at the top of the storage tank to protect the materials in the tank from being nitridated and the safety of the storage tank. The nitrogen sealing device is composed of two parts: ZZDQ quick relief valve and ZZV micro-pressure regulating valve. The quick relief valve is composed of a pressure controller and a ZMQ-16K single-seat shut-off valve.

Item NO.:

XUVAL77-66Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

10Nitrogen sealing device

When the pressure in the storage tank rises to the set pressure, the quick relief valve opens quickly to release the excess pressure in the tank. When the pressure in the storage tank decreases, the micro-pressure regulating valve opens the valve to fill the tank with nitrogen. Because the micro-pressure regulating valve must be used at a pressure below 0.1Mpa, the site pressure is relatively high, and the ZZYP type pressure regulating valve must be installed to reduce the pressure of the pressure regulating valve to below 0.1Mpa before it can be used. The nominal pressure is 0.1Mpa, the pressure can be set in sections, from 0.5Kpa to 66 Kpa or less, and the temperature of the medium is less than or equal to 80°C.

Features of Nitrogen Sealing Device:

The nitrogen supply (discharge) pressure of the nitrogen sealing device is convenient to set, and it can be carried out under the conditions of continuous production;

The nitrogen pressure has a wide setting range, as low as 0.5Kpa (50mm.w.c), as high as Kpa, with a ratio of 132 times. The effective area of the pressure detection diaphragm is large, the set spring stiffness is small, and the action is extremely sensitive.

Nitrogen seal valve adjustment:

Nitrogen supply pressure adjustment: select a set value such as 1Kpa (100mm.w.c) within the pressure adjustment range of the ZZV type micro-pressure regulator, and adjust the adjustment screw 2 to change the pre-compression (tension) amount of the spring 3 to achieve;

Nitrogen relief pressure adjustment: In the pressure controller part of the ZZDQ quick relief valve, it is achieved by adjusting the seat 3 and changing the pre-compression of the spring 4. Generally, in order to avoid frequent opening and closing of the nitrogen sealing device, the nitrogen release setting value should be far away from the nitrogen supply pressure value, such as 2Kpa (200mm.w.c);

Breathing valve high setting value adjustment: After the above two setting values are adjusted, in order to avoid frequent opening and closing of the breathing valve, the setting value of the breathing valve should be greater than the pressure relief setting value.

Nitrogen sealing valve device is a kind of self-operated control valve. There are many kinds of self-operated control valves according to the application medium, including air, nitrogen, steam, and liquid. The top of the storage tank is generally equipped with a breathing valve. When the toxic medium storage tank reaches a stable liquid level, the pressure on the top of the tank is equal to the vapor pressure of the medium at that temperature. When the breathing valve is exhaled, the toxic medium will be discharged outside the tank, which is likely to cause personnel poisoning. In order to avoid the volatilization of the toxic medium It is necessary to maintain a certain pressure on the liquid surface of the tank top to avoid volatilization of toxic media and then emptying. Generally, nitrogen is used to maintain this pressure, which is called nitrogen sealing.

The nitrogen sealing valve and nitrogen sealing device produced by the valve are a set of self-operated micro-pressure control system independently developed and developed, which is only used to keep the pressure of the protective gas (usually nitrogen) at the top of the container constant to avoid direct contact between the material in the container and the air , To prevent the volatilization and oxidation of materials, and the safety of the container. It is especially suitable for the gas seal protection system of various large storage tanks. The product has the characteristics of energy saving, sensitive action, reliable operation, convenient operation and maintenance, etc. It is widely used in petroleum, chemical and other industries.

Features of nitrogen sealing valve and nitrogen sealing device:

1. No additional energy is required, and it can work in places without electricity or gas, which is convenient, saves energy and reduces costs.

2. The nitrogen supply and discharge pressure of the nitrogen sealing device is convenient to set, and it can be carried out under the condition of continuous production.

3. The effective area of the pressure detection diaphragm is large, the spring stiffness is small, the action is sensitive, and the device works smoothly.

4. Adopting no packing design, the friction force on the valve stem is small, the response is fast, and the control accuracy is high.

5. The nitrogen supply device is operated by a pilot, the decompression ratio can reach 100:1, the decompression effect is good, and the control accuracy is high.

The nitrogen sealing valve device consists of two parts: a nitrogen supply device and a nitrogen discharge device. The nitrogen supply device is composed of a pilot and a main valve; the nitrogen discharge device is composed of a pressure-open micro-pressure regulating valve with internal feedback. The nitrogen pressure is generally set to 100mm/day 20, which is precisely controlled by a nitrogen sealing device. When the liquid inlet valve of the storage tank is opened. When materials are added to the tank, the liquid level rises, the volume of the gas phase part decreases, and the pressure rises. When the pressure in the tank rises above the pressure setting value of the nitrogen discharge device, the nitrogen discharge device opens. Nitrogen is released to the outside, the pressure in the tank drops, and when the pressure of the nitrogen discharge device is lowered to the set point, the nitrogen discharge device is automatically closed. When the outlet valve of the storage tank is opened and the user discharges the material, the liquid level drops, the volume of the gas phase part increases, the pressure in the tank decreases, the nitrogen supply device opens, and nitrogen is injected into the storage tank to increase the pressure in the tank. When the pressure in the tank rises Until the nitrogen supply device is automatically closed.

The nitrogen sealing valve device is mainly used for the constant control of the nitrogen pressure at the top of the storage tank to protect the materials in the tank from being nitridated and the safety of the storage tank. The nitrogen sealing valve device consists of two parts: a quick relief valve and a micro-pressure regulating valve. The quick relief valve is composed of a pressure controller and a single-seat shut-off valve.

When the pressure in the storage tank rises to the set pressure, the quick relief valve opens quickly to release the excess pressure in the tank. When the pressure in the storage tank decreases, the micro-pressure regulating valve opens the valve to fill the tank with nitrogen. Because the micro-pressure regulating valve must be used at a pressure below 0.1Mpa, the pressure at the site is relatively high, and a pressure regulating valve must be installed to reduce the pressure to below 0.1Mpa before it can be used. The nominal pressure is 0.1Mpa, the pressure can be set in sections, from 0.5Kpa to 66Kpa or less, and the medium temperature is 180°C.

The nitrogen supply (discharge) pressure of the nitrogen sealing valve device is convenient to set, and can be carried out under continuous production conditions; the nitrogen pressure setting range is wide, as low as 0.5Kpa (50mm.wc), as high as Kpa, and the ratio is 132 times , The effective area of the pressure detection diaphragm is large, the spring stiffness is small, and the action is extremely sensitive.

Nitrogen supply pressure adjustment: select a set value such as 1Kpa (100mm.w.c) within the pressure adjustment range of the micro-pressure regulator, and adjust the adjustment screw 2 to change the pre-compression (tension) amount of the spring 3 to achieve;

Nitrogen relief pressure adjustment: In the pressure controller part of the quick relief valve, the pre-compression amount of the spring 4 is changed by adjusting the seat 3. Generally, in order to avoid frequent opening and closing of the nitrogen sealing device, the nitrogen release setting value should be far away from the nitrogen supply pressure value, such as 2Kpa (200mm.wc), and the breathing valve high setting value adjustment: after the above two setting values are adjusted, in order to avoid breathing The valve opens and closes frequently, and the set value of the breathing valve should be greater than the set value of pressure relief.

Electric control valve, self-operated pressure control valve, nitrogen sealing device, these products are widely used in petroleum, chemical industry, electric power, metallurgy, military industry, shipbuilding, light industry, papermaking, printing and dyeing, medicine and environmental protection engineering and many other fields.

Installation matters of nitrogen sealing device:

(1) Before installation, check whether the parts of the whole machine are damaged or loose. The pipeline should be cleaned, and the flow direction of the medium should be consistent with the arrow on the valve body.

(2) In order to facilitate on-site maintenance and operation, proper space should be reserved around the valve, bypass manual valve and valve block installation plan should be set.

(3) The valve should be installed upright and vertically on a horizontal pipeline, and the valve body should be connected to the pipe by the dust. Pay attention to the coaxiality, and should be installed in an environment where the ambient temperature does not exceed -25~55℃.

Model of ZZV micro-pressure regulating valve: ZZV V230

ZZV micro-pressure regulating valve Nominal diameter: 25MM-100MM

ZZV micro-pressure regulating valve Working pressure: 1.6MPa -2.5MPAa

ZZV micro-pressure regulating valve Connection mode: flange connection

ZZV micro-pressure regulating valve Form: self-operated

ZZV micro-pressure regulating valve main function: control pressure

ZZV micro-pressure regulating valve Medium: all kinds of medium

ZZV micro-pressure regulating valve Material: WCB cast steel stainless steel

ZZV micro-pressure regulating valve Standard: Ministry of Machinery standard or customized non-standard

Nitrogen sealing device parts materials:

Part Name

Material

Body

ZG230-450 ZG1Cr18i9Ti

Stem, core, seat

1Cr18i9Ti

Diaphragm

Nitrile rubber clip reinforced polyester fabric

Spring

60Si2Mn

Bellows

1Cr18i9Ti

Main technical parameters of nitrogen sealing device:

0.5~5.5、5~10、9~14、13~19、18~24、23~28

27~33、31~38、36~44、42~51、49~58、56~66

Nominal diameter DN(mm)

20

25

32

40

50

65

80

100

Rated flow coefficient (KV)

8

11

20

32

50

80

100

160

Rated stroke (mm)

6

8

10

15

20

Nominal pressure PN (Mpa)

0.10

Pressure adjustment range (MPa)

Medium temperature (℃)

≤80℃

Adjustment accuracy (%)

±10

Allowable leakage (L/h)

10ˉ4×rated capacity of valve

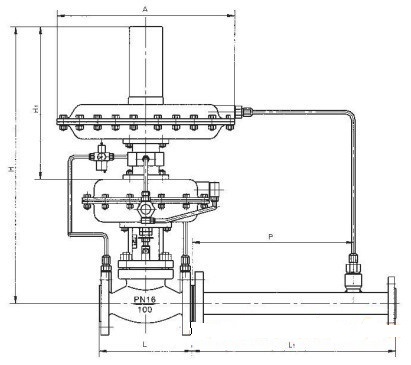

Nitrogen sealing device specifications and weight:

Nominal diameter DN

20

25

32

40

50

65

80

100

A

192

232

308

H

629

631

352

666

689

797

837

1050

L

150

160

180

200

230

290

310

350

G(kg)

18

19

21

23

25

37

50

59

Nitrogen sealing device flange specifications:

Nominal diameter DN

20

25

32

40

50

65

80

100

D

105

115

140

150

165

185

200

220

D1

75

85

100

110

125

145

160

180

B

16

18

20

22

n-∅d

4-14

4-18

8-18

f1×D2

2×56

3×65

3×76

3×84

3×99

3×118

3×132

3×156

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported