Overview of pneumatic angle seat valve: Pneumatic angle seat valve is a new generation of pneumatic angle seat valve developed by introducing advanced foreign production technology and combining modern industrial applications. Pneumatic angle seat valves are widely used in food and chemical processes, sterilization machines, high-pressure disinfection and dry cleaning machines, clothes dryers, beer production, etc.

Item NO.:

XUVAL77-63Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10Internal thread stainless steel pneumatic angle seat valve

Features of Pneumatic Angle Seat Valve:

1. Visual position indication: limit switch or emergency manual device can be connected.

2. Easy to install: The pneumatic control head can be rotated 360°, and even the limit switch can be rotated 360°. One or two limit switches can be easily installed.

3. Advanced pneumatic controller: thickened engineering plastic shell, safe and reliable. Low-wear piston structure, easy to large and low gas consumption. No internal parts are self-lubricating and maintenance-free.

4. It has a variety of control methods: normally open, normally closed, double action.

5. A smaller pneumatic actuator is required: when fluid flows from above the valve stem, a smaller control head can be selected.

6. Easy to connect: MAMUR standard connection, embedded metal connector.

7. Long-life guide rod: The valve stem is sealed with tapered Teflon (PTEE) to avoid the introduction of dirt. Self-lubricating and maintenance-free. The valve stem is specially treated to ensure the best fixation and can automatically correct its position.

8. No water hammer effect: When fluid flows in from below the valve stem, water hammer (water impact) is absorbed.

9. Advanced valve body mechanism: The flow rate is 30% larger than the ordinary angle seat, the volume is smaller, and the fluid flow pattern is better. Stainless steel 316 valve body, Teflon seal, high temperature resistance and corrosion resistance. Life span of up to 7 million times.

Technical parameters of pneumatic angle seat valve:

Nominal diameter

DN(mm)

15-100

Nominal pressure

PN(MPa)

1.0

1.6

Test pressure Ps(MPa)

Strength test

1.5

2.4

Sealing test

1.1

1.76

Hermetic test

0.2~0.7MPa

Applicable medium

Water, steam, gas, acid, alkali, etc.

Proper temperature

-15℃~180℃

Actuator

Model

Watt

Air pressure

0.4~.0.7MPa

Technical characteristics of pneumatic angle seat valve:

Interface G

3/8A

3/8B

1/2A

1/2B

3/4A

3/4B

3/4B

A

A

11/4

11/2

11/2

2

2

Diameter (mm)

15

15

15

15

20

20

20

25

25

32

40

40

50

50

KV(m³/h)

4.5

4.5

5.3

5.7

9.2

10.5

10.8

20

20

29

46

46.5

59

67

Control air source (MPa)

The smallest

4.2

4

4.2

4

4.2

3

4

4

4

4

4

4

4

1.8

4Maximum

10

10

10

10

10

10

10

10

10

8

8

8

8

8

Maximum pressure resistance (MPa)

1

16

16

16

16

8

10/16

16

11/16

16

14/16

16

4.4

40/16

Weight (Kg)

1

1.1

1

1

1.2

1.2

1.2

16

1.7

3

1.7

4

4

5.3/7.6

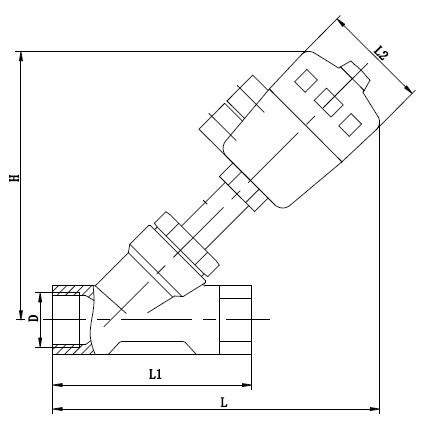

Main connection dimensions of pneumatic angle seat valve:

Power on

DN

L

L1

L2

H

D

Actuator

15

180

120

64

137

50.5

50

20

185

140

64

145

50.5

50

25

210

160

80

173

50.5

63

32

240

176

80

210

50.5

63

40

250

190

80

260

50.5

63

50

330

210

100

301

64

80

Possible failures of pneumatic angle seat valves and their troubleshooting methods:

Malfunction

The reason

Elimination method

Can't open

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

J744X Hydraulic Angle Mud ValveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported