Product introduction: HH49X micro-resistance slow-closing butterfly check valve can be used in the drainage pipeline of clean water, sewage, sea water and other media. It can not only prevent the medium from flowing back, but also effectively limit the destructive water hammer and ensure the safe use of the pipeline. It is not suitable for medium containing solid particles and particles with high viscosity.

Item NO.:

XUVAL77-118Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10HH49X micro-resistance slow-closing butterfly check valve

The micro-resistance slow-closing butterfly check valve has novel structure, small size, light weight, low fluid resistance, reliable sealing, stable opening and closing, abrasion resistance, long service life, oil pressure and slow closing are not affected by the medium. Good energy-saving effect and other characteristics.

It is mainly composed of a valve body, two semi-circular valve discs, a return spring, an oil storage cylinder, a slow closing small cylinder group, and a needle valve (micro regulating valve). The principle mainly relies on the thrust of the imported medium to push the two discs apart smoothly. At the same time, the imported pressure medium enters the lower part of the piston in the oil cylinder, pushing the piston, and pressing the oil on the upper part of the piston into the tail end of the small cylinder on both sides of the valve body through the needle valve, so that the piston rod in the small cylinder is extended. When the inlet medium pressure drops below the outlet pressure, the medium will flow back. At this time, the valve flap will automatically close under the action of the spring and the medium backflow. However, because the piston rod is in the extended position, the valve flap cannot be fully closed when it is pressed against it. There is about 20% of the area left for the medium to pass through, thereby eliminating the water hammer. The valve disc is divided into two steps by the piston to close quickly and then slowly, so as to prevent the motor from reversing and eliminate the mute effect.

Product name: Micro-resistance slow-closing check valve

Product model: HH49X, HH46X, HH48X

Applicable medium: water and oil

Slow closing time: 3-60 seconds

Nominal pressure: 1.0-2.5MPA

Nominal diameter: 40-800mm

Applicable temperature: 0-80℃ (up to 200℃ if necessary)

Flange standard: GB/T 17241.6GB/T9113

Test standard: GB/T 13927 AP1598

Structural features and uses:

This valve is a safety device installed in the pipeline or at the outlet of the water pump to prevent the pressure difference and water hammer in the pipeline from impacting the reverse rotation of the water pump when the pump is stopped. With novel structure, small size, light weight, fluid

It has the characteristics of low resistance, reliable sealing, stable opening and closing, long service life, and good energy-saving effect.

It is suitable for the related pipelines of water supply and drainage, fire fighting, HVAC and other systems or at the outlet of the pump to prevent the water hammer caused by the backflow of the medium from damaging the pump and the pipeline, forming a noise reduction effect.

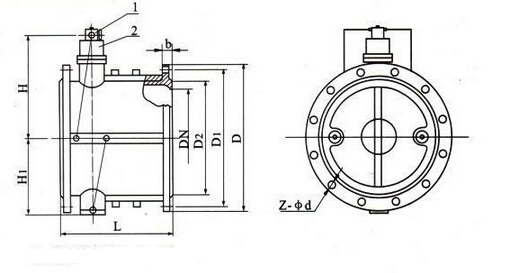

Connection size:

DN

40

50

65

80

100

125

150

200

250

300

L

140

150

170

180

190

200

210

230

250

270

H

200

215

225

235

280

290

310

350

415

450

H1

88

98

108

118

130

148

172

210

240

264

The main technical parameters:

Nominal pressure PN(mm)

1.0

1.6

Test pressure (MPa)

Shell strength

1.5

2.4

Sealing performance

1.1

1.76

Working temperature (℃)

≤80

Applicable medium

Clean water, sewage, sea water

Slow closing time (S)

0-60

Material of main parts:

Part Name

Body

Disc

Valve stem, oil cylinder, oil plug

Spring

Seat

Material

Cast iron, carbon steel

Carbon steel, stainless steel

Stainless steel

Stainless steel

Nitrile rubber

Product Structure:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

Material 2205 DN50 dual phase steel check valve swing valvenext :

H74F46 fluorine lined wafer check valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported