All welded ball valves are widely used in city gas,urban heating,petrochemical,shipbuilding,steel,pressure regulating stations,power plants and other types of pipeline equipment.

Item NO.:

XU134Lead Time:

40DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

YellowMOQ:

50Welded ball valve material:

1 : Body: carbon steel ST37.0, A106-B;20 # steel

2 : sphere: stainless steel 304 or 316

3 : Stem: 2Cr13

4 : valve stem seal: perfluorine like glue

5 : Ball seal: RTFE (PTFE+C)

Standard features for all welded ball valves:

1 : Diameter: DN15 ~1000

2 : Pressure: Pn 16 ~ 40

3 : Working temperature: -29℃ ~ +200℃

4 : gas pipeline welding ball valve suitable for the medium: oil/gasoline, liquefied natural gas/liquefied petroleum gas, petrochemical, iron and steel plant, heating pipeline, etc

5 : gas pipeline welding ball valve operation mode: handle, gear (vertical/horizontal), electric, turbine.

welded ball valve applications:

1 : Urban gas: gas output pipeline, main line and branch supply pipeline, etc.

2 : Central heating: output pipelines, main lines and branches of large heating equipment.

3 : heat exchanger: opening and closing of pipelines and loops.

4 : steel plant: all kinds of fluid pipeline, exhaust gas discharge pipeline, gas and heat supply pipeline, fuel supply pipeline.

5 : all kinds of industrial equipment, all kinds of heat treatment pipes, all kinds of industrial gas and heat pipes.

1 : No need for maintenance, adjustment and lubrication, easy installation, long-term reliable operation at low operating costs.The surface is sprayed with plastic treatment technology, and the luster is beautiful, which has been in the leading level in China.There will be no external leakage and other phenomena.The body is welded construction, so the valve is light weight and easy to insulate.It is very simple to install the adjusting mechanism, and the operating handle can be removed and reversed for installation.

2 : Because the valve seat is made of carbon fiber reinforced Teflon seal ring and disc spring, so the pressure and temperature change adaptability is strong, in the marked pressure and temperature range will not produce any leakage.

3 : The machining process of the sphere is tracked and detected by advanced computer detector, so the machining precision of the sphere is high.

4 : Because the valve body material is the same as the pipeline material, there will be no uneven stress, and it will not be deformed due to earthquakes and vehicles passing through the ground, and the pipeline is aging resistant.

5 : integral full welding, equal diameter and variable diameter channel, using fixed ball and floating ball, double piston effect sealing system, automatic injection of sealant bearing.

6 : In order to prevent static electricity, steel ball and spring are installed between the valve stem and the ball and the valve stem and the packing box respectively, which can keep all parts of the valve and the valve body conductive, let the current pass through the area, release static electricity.Not only prevent fire, and prevent corrosion, to achieve temporary cut off, in order to timely maintenance.

7 : the stem anti-detachment function is because the stem is affected by the pressure in the valve, always produces the force of detachment, so the stem is designed into anti-detachment structure.

8 : The pressure is pushed to the stem with the thrust washer support of low friction material, so that the stem only plays the role of transferring torque.

Scope of application

Natural gas pipeline,city gas.

Applicable medium

Natural gas,gas,gas and other fluids that do not chemically react with carbon steel.

Temperature range

-29℃~200℃

Testing standard

API 598

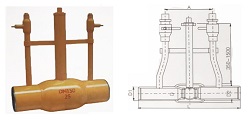

| Main dimensions | |||||||

|

DN |

NPS |

A |

D |

D1 |

D2 |

L |

|

| GB | EN | ||||||

| 50 | 2 | 300 | 40 | 57 | 60.3 | 89 | 1000 |

| 65 | 2 1/2 |

300 |

50 | 76 | 76.1 | 114 |

1000 |

| 80 | 3 |

300 |

65 | 89 | 88.9 | 140 |

1000 |

| 100 | 4 | 340 | 80 | 108 | 114.3 | 165 |

1000 |

| 125 | 5 | 400 | 100 | 133 | 141.3 | 216 |

1000 |

| 150 | 6 |

400 |

125 | 159 | 168.3 | 219 |

1000 |

| 200 | 8 |

400 |

150 | 219 | 219.1 | 267 |

1000 |

| 250 | 10 |

400 |

200 | 273 | 273.1 | 355 |

1000 |

| 300 | 12 | 500 | 250 | 325 | 323.9 | 457 | 1100 |

| 350 | 14 |

500 |

300 | 377 | 355.6 | 508 | 1250 |

| 400 | 16 |

500 |

337 | 426 | 406.4 | 558 | 1360 |

| 450 | 18 |

500 |

337 | 477 | 457.2 | 558 | 1440 |

| 500 | 20 | 600 | 387 | 530 | 508 | 660 | 1510 |

| 550 | - |

600 |

438 | - | - | 718 | 1690 |

| 600 | 24 | 650 | 489 | 630 | 609.6 | 812 | 1660 |

| 650 | - |

650 |

540 | - | 660.6 | 898 | 1840 |

| 700 | 28 | 700 | 591 | 730 | 711.2 | 1016 | 1940 |

| 750 | - | 700 | 635 | - | 738 | 1020 | 2000 |

| 800 | 32 | 800 | 686 | 830 | 812.8 | 1095 | 2120 |

| 850 | - | 800 | 737 | - | 863.6 | 1172 | 2220 |

| 900 | 36 | 800 | 781 | 930 | 914.4 | 1245 | 2400 |

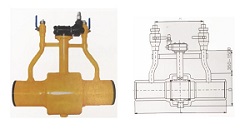

|

Main dimensions |

||||

| DN | NPS | A | L | D |

| 50 | 2 | 300 | 1000 | 110 |

| 65 | 2 1/2 | 300 | 1000 | 138 |

| 80 | 3 | 300 | 1000 | 165 |

| 100 | 4 | 300 | 1000 | 165 |

| 150(H) | 6 | 400 | 1000 | 200 |

| 150(G) | 6 | 400 | 1000 | 300 |

| 200 | 8 | 400 | 1000 | 380 |

| 250 | 10 | 400 | 1000 | 450 |

| 300 | 12 | 500 | 1200 | 550 |

| 400 | 16 | 500 | 1480 | 670 |

| 500 | 20 | 600 | 1765 | 800 |

| 600 | 24 | 650 | 1800 | 970 |

| 650 | - | 650 | 1850 | 1050 |

| 700 | 28 | 700 | 1950 | 1090 |

| 750 | - | 750 | 2000 | 1180 |

| 800 | 32 | 800 | 2150 | 1245 |

| 850 | - | 850 | 2200 | 1360 |

| 900 | 36 | 900 | 2400 | 1420 |

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45 days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported