A40Y full swing safety valve with radiator spring overview: A40Y full swing safety valve with radiator spring is suitable for equipment or pipelines with air, water, nitrogen and hydrogen mixture with working temperature ≤ 400 ℃ and A40Y spring high temperature safety valve ≤ 450 ℃, and A40Y-P stainless steel with radiator spring full swing safety valve is suitable for equipment or pipelines with corrosive medium with working temperature ≤ 300 ℃, and it is used as overpressure protection device.

Item NO.:

XUVAL77-69Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

SilveryMOQ:

10A40Y spring full open safety valve with radiator

Model of high temperature safety valve: A40Y

Nominal diameter of high temperature safety valve: 15mm-200mm

Service pressure of high temperature safety valve: 1.6MPa-10.0MPa

Connection mode of high temperature safety valve: flange connection

High temperature safety valve type: spring type

Main function of high temperature safety valve: pressure relief and protection

Medium for high temperature safety valve: water, oil and steam

High temperature safety valve material: cast steel, stainless steel, chrome molybdenum steel

High temperature safety valve standard: mechanical standard or customized non-standard

Main parts and materials of A40Y spring full open safety valve with radiator:

SA40Y-16C

SA40Y-16P

SA40Y-16I

SA40Y-25

SA40Y-25P

SA40Y-25I

SA40Y-40

SA40Y-40P

SA40Y-40I

SA40Y-64

SA40Y-64P

SA40Y-64I

SA40Y-100

SA40Y-100P

SA40Y-100I

NO.

Part name

A40Y-C material

A40Y-P material

A40Y-i material

1

Body

WCB

ZG1Cr18Ni9Ti

ZG1Cr5Mo

2

Seat

2Cr13

1Cr18Ni9Ti

1Cr18Ni9Ti

3

Adjusting ring

2Cr13

1Cr18Ni9Ti

1Cr18Ni9Ti

4

Disc

2Cr13

1Cr18Ni9Ti

1Cr18Ni9Ti

5

Guide sleeve

2Cr13

1Cr18Ni9Ti

1Cr18Ni9Ti

6

Radiator

ZG230-450

ZG230-450

ZG230-450

7

Bonnet

ZG230-450

ZG230-450

ZG230-450

8

Spring

50CrVA

50CrVA coated fluoroplastics

50CrVA coated fluoroplastics

9

Stem

2Cr13

1Cr18Ni9Ti

2Cr13

10

Adjusting screw

45

1Cr18Ni9Ti

2Cr13

11

Valve cap

ZG200-400

ZG200-400

ZG200-400

12

Sealing surface material

Surfacing Co based cemented carbide

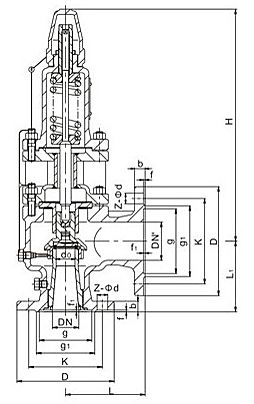

Overall dimension and connection dimension of A40Y spring full lift safety valve with radiator:

Model

Nominal diameter

do

D

K

g

g1

b

f

f1

Z-∅d

DN

D1

K1

g3

g2

b1

f'

f1'

Z1-∅d1

L

L1

≈H

20

15

105

75

55

16

2

4-14

25

115

85

65

16

2

4-14

110

95

518

25

16

115

85

65

16

2

4-14

32

140

100

78

18

2

4-18

110

95

518

32

20

140

100

78

18

2

4-18

40

150

110

85

18

3

4-18

115

100

518

40

25

150

110

85

18

3

4-18

50

165

125

100

20

3

4-18

120

110

579

50

32

165

125

100

20

3

4-18

65

185

145

120

20

3

4-18

135

120

639

65

40

185

145

120

20

3

4-18

80

200

160

135

20

3

8-18

160

140

671

80

50

200

160

135

20

3

8-18

100

220

180

155

22

3

8-18

170

135

676

100

65

220

180

155

22

3

8-18

125

250

210

185

22

3

8-18

195

175

787

125

80

250

210

185

22

3

8-18

150

285

240

210

24

3

8-23

210

190

977

150

100

285

240

210

24

3

8-23

175

310

270

240

26

3

8-23

255

230

1035

200

125

340

295

265

26

3

12-23

250

405

355

320

30

3

12-26

300

260

1193

20

15

105

75

55

16

2

4-14

25

115

85

65

16

2

4-14

110

95

518

25

16

115

85

65

16

2

4-14

32

140

100

78

18

2

4-18

110

95

518

32

20

140

100

78

18

2

4-18

40

150

110

85

18

3

4-18

115

100

518

40

25

150

110

85

18

3

4-18

50

165

125

100

20

3

4-18

120

110

579

50

32

165

125

100

20

3

4-18

65

185

145

120

20

3

4-18

135

120

639

65

40

185

145

120

22

3

8-18

80

200

160

135

20

3

8-18

160

140

671

80

50

200

160

135

22

3

8-18

100

220

180

155

22

3

8-18

170

135

676

100

65

230

190

160

24

3

8-23

125

250

210

185

22

3

8-18

195

175

787

125

80

270

220

188

28

3

8-26

150

285

240

210

24

3

8-23

210

190

977

150

100

300

250

218

30

3

8-26

175

310

270

240

26

3

8-23

255

230

1035

200

125

360

310

278

34

3

12-26

250

405

355

320

30

3

12-26

300

260

1193

20

15

105

75

51

55

16

2

4

4-14

25

115

85

65

16

2

4-14

110

95

518

25

16

115

85

58

65

16

2

4

4-14

32

140

100

78

18

2

4-18

110

95

518

32

20

140

100

66

78

18

2

4

4-18

40

150

110

85

18

3

4-18

115

100

518

40

25

150

110

76

85

18

3

4

4-18

50

165

125

100

20

3

4-18

120

110

579

50

32

165

125

88

100

20

3

4

4-18

65

185

145

120

20

3

4-18

135

120

639

65

40

185

145

110

120

22

3

4

8-18

80

200

160

135

20

3

8-18

160

140

671

80

50

200

160

121

135

22

3

4

8-18

100

220

180

155

22

3

8-18

170

135

676

100

65

235

190

150

160

24

3

4.5

8-23

125

250

210

185

22

3

8-18

195

175

787

125

80

270

220

176

188

28

3

4.5

8-26

150

285

240

210

24

3

8-23

210

190

977

150

100

300

250

204

218

30

3

4.5

8-26

175

310

270

240

26

3

8-23

255

230

1035

20

10

125

90

51

68

22

2

4

4-18

25

115

85

58

65

16

2

4

4-14

96

85

384

25

16

140

100

58

78

22

2

4

4-18

2

140

100

66

78

18

2

4

4-18

110

100

384

32

20

155

110

66

82

24

2

4

4-23

40

150

110

76

85

18

3

4

4-18

130

110

396

40

25

170

125

76

95

24

3

4

4-23

50

165

125

88

100

20

3

4

4-18

130

120

426

50

32

180

135

88

105

26

3

4

4-23

65

185

145

110

120

22

3

4

8-18

135

130

504

65

40

205

160

110

130

28

3

4

8-23

80

200

160

121

135

22

3

4

8-18

175

160

613

80

50

215

170

121

140

30

3

4

8-23

100

235

190

150

160

24

3

4.4

8-23

175

160

603

100

65

250

200

150

168

32

3

4.5

8-26

125

270

220

176

188

28

3

4.5

8-25

195

195

813

150

100

345

280

204

240

38

3

4.4

8-34

200

375

320

260

282

38

3

4.5

12-30

280

265

1064

20

10

125

90

51

68

22

2

4

4-18

25

115

85

58

65

16

2

4

4-14

96

85

384

25

16

140

100

58

78

24

2

4

4-18

32

140

100

66

78

18

2

4

4-18

110

100

384

32

20

155

110

66

82

24

2

4

4-23

40

150

110

76

85

18

3

4

4-18

130

110

396

40

25

170

125

76

95

26

3

4

4-23

50

165

125

88

100

20

3

4

4-18

130

120

426

50

32

195

145

88

112

28

3

4

4-26

65

185

145

110

120

22

3

4

8-18

135

130

504

65

32

220

170

110

138

32

3

4

8-26

80

200

160

121

135

22

3

4

8-18

175

160

613

80

40

230

180

121

148

34

3

4

8-26

100

235

190

150

160

24

3

4.5

8-23

175

160

603

100

50

265

210

150

172

38

3

4.5

8-30

125

270

220

176

188

28

3

4.5

8-25

195

195

813

150

80

355

290

204

250

46

3

4.5

12-34

200

375

320

260

282

38

3

4.5

12-30

280

265

1064

Product structure chart:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

CS49H disc flange steam trapnext :

900X emergency shut off valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported