Product introduction: Model 300X slow closing check valve is composed of main valve, check valve, needle valve, ball valve, micro filter and pressure gauge. Using hydraulic automatic operation, the main valve can get the best opening and closing speed. To prevent the water hammer from hitting, in order to achieve the effect of slow closing and silencing.

Item NO.:

XUVAL77-21Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

blueMOQ:

10

300X(HH741X) slow closing check valve

Product introduction:

Model 300X slow closing check valve is composed of main valve, check valve, needle valve, ball valve, micro filter and pressure gauge. Using hydraulic automatic operation, the main valve can get the best opening and closing speed. To prevent the water hammer from hitting, in order to achieve the effect of slow closing and silencing.

Performance parameters:

Nominal diameter of 300X slow closing check valve: DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500, DN600, etc.

300X slow closing check valve nominal pressure size: PN10, PN16 and PN25.

Working principle:

When the valve supplies water from the inlet end, the water enters the main valve control room through the micro filter, needle valve and one-way valve, and then discharges to the downstream through the ball valve. Because the opening of the needle valve is less than that of the ball valve, that is, the drainage speed of the main valve control room is greater than that of the water inlet, the pressure in the control room is reduced, and the inlet pressure acting on the lower end of the main valve disc opens the main valve to supply water to the downstream. When the pipeline stops supplying water, if the downstream water begins to flow back, a part of the return water will enter the main control room through the ball valve. Due to the action of the one-way valve, the return water can not flow out from the main control room, causing the main control room leakage.

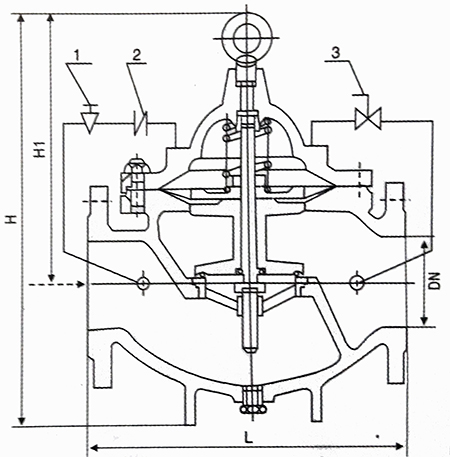

Structure diagram:

Note: 1 for needle valve, 2 for check valve, 3 for small ball valve.

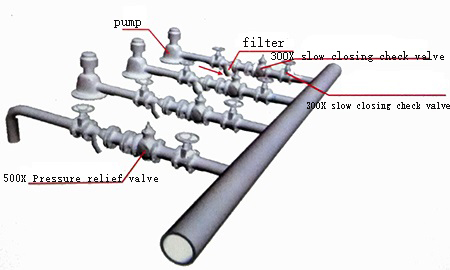

Installation diagram:

Main dimensions:

| DN | L | A1 | A | H1 | H | F |

| 20 | 150 | 200 | 282 | 106 | 172 | 116 |

| 25 | 160 | 200 | 282 | 106 | 172 | 116 |

| 32 | 180 | 200 | 282 | 106 | 172 | 116 |

| 40 | 200 | 210 | 320 | 137 | 225 | 168 |

| 50 | 220 | 210 | 320 | 137 | 225 | 168 |

| 65 | 240 | 215 | 330 | 145 | 270 | 180 |

| 80 | 260 | 220 | 330 | 178 | 289 | 210 |

| 100 | 295 | 230 | 410 | 232 | 375 | 284 |

| 125 | 330 | 245 | 420 | 286 | 420 | 310 |

| 150 | 350 | 260 | 420 | 318 | 450 | 370 |

| 200 | 400 | 280 | 430 | 413 | 722 | 463 |

| 250 | 475 | 300 | 450 | 502 | 769 | 525 |

| 300 | 550 | 320 | 460 | 600 | 906 | 625 |

| 350 | 620 | 340 | 470 | 628 | 1480 | 705 |

| 400 | 700 | 360 | 480 | 677 | 1027 | 778 |

| 450 | 750 | 360 | 480 | 677 | 1027 | 778 |

| 500 | 800 | 410 | 780 | 750 | 1110 | 690 |

| 600 | 900 | 456 | 888 | 850 | 1286 | 785 |

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

If you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported