Product overview of 100D fixed water level valve: 100D fixed water level valve is a diaphragm valve that adjusts the height of the liquid level of the water tank and water tower. The fixed water level valve is controlled by a floating ball. When the liquid level reaches the set height, the valve transmits a signal to the water pump through the relevant structure, and the water pump stops water supply; when the liquid level is lower than the social fixed position, the water pump automatically starts water supply.

Item NO.:

XUVAL77-55Lead Time:

45DaysProduct Orgin:

CHINABrand:

XUVALShipping Port:

ShanghaiPayment:

100%TTColor:

BlueMOQ:

10100D fixed water level valve

The fixed water level valve operates smoothly, effectively preventing the water hammer when the pump is turned on and when the pump is stopped, and avoids excessive pressure in the pipeline. The fixed water level valve is suitable for the automatic water supply system of water tanks and water towers. The valve is simple to maintain, flexible and durable, and has high accuracy in liquid level control. The water level is not interfered by water pressure and closes tightly without water leakage. It has reliable performance.

100D fixed water level valve structure and use:

The 100D fixed water level valve is used in the automatic water supply system of the pool or water tower. When the liquid level reaches the set height, the valve transmits the signal to the water pump through the related structure, and the water pump stops water supply. When the liquid level is lower than the set position, the water pump automatically starts water supply , It can effectively prevent water hammer when the pump is stopped, and avoid excessive pressure in the pipeline. The 100S angle type mud valve has sensitive control and high accuracy of liquid level control. The water level is not disturbed by water pressure and closes tightly without water leakage. It has reliable performance and service life long.

Key Points for Design and Selection of 100D Constant Water Level Valve:

1. The hydraulic control valve used in the engineering type is a product that has passed the inspection of the manufacturer, has a complete variety of signs, and the technical data meets the requirements.

2. According to the functional requirements, select the type of valve, and then determine the material of the valve body and sealing part according to the pipeline transportation medium, temperature, construction standards and requirements of the owner. Commonly used valve body materials are cast iron, copper iron, copper, plastics and so on. Commonly used sealing surface and lining materials are copper alloy, plastic, steel, cemented carbide, rubber, etc. The valve body material should match the pipe material.

3. The nominal pressure of the valve has different levels such as 0.6, 1.0, 1.6, 2.5 and 4.0MPa. The working pressure of the medium transported by the pipeline should be less than the nominal pressure of the valve.

4. The installation of hydraulic control valves in the project should have enough space for management, operation, installation and maintenance, and should meet the requirements of pipelines for valves.

5. When the pipeline adopts flange connection, the flange connection hydraulic control valve should be adopted; when the pipeline adopts the groove connection, the groove connection hydraulic control valve should be adopted.

6. The water conservancy control valve should be installed on the pipeline where the medium flows in one direction.

7. The direction of the arrow on the main valve body of the water conservancy control valve must be consistent with the flow direction of the pipeline system.

8. There should be no air blockage or air resistance in the pipe section of the hydraulic control valve. An automatic exhaust valve should be installed in the high position of the pipe network and other gas storage sections.

9. When the valve is installed horizontally, the valve cover and valve stem should face upwards. When installed vertically, the valve cover and valve stem should face outwards.

10. The strength and tightness test should be done before the valve is installed.

11. The strength and tightness test of the valve should meet the following requirements.

Working principle of 100D fixed water level valve:

When water enters the pipeline from the water inlet end to make the water level reach a high level, the floating ball pilot valve opens the control channel that enters the main valve, and the pressure in the control room increases, causing the main valve to close. When the water level drops to a low water level, the floating ball pilot valve closes the control channel into the main valve and allows the control room to communicate with the atmosphere. If pressure cannot be formed in the control room, the inlet pressure entering the main valve disc will hold up the main valve and open it. The main valve disc supplies a large amount of water to the water tank or pool.

Main technical parameters of 100D fixed water level valve:

Nominal pressure (Mpa)

Shell test pressure (MPa)

Seal test pressure (MPa)

Applicable medium

Medium temperature (℃)

1.0

1.5

1.1

water

0~80

1.6

2.4

1.76

2.5

3.75

2.75

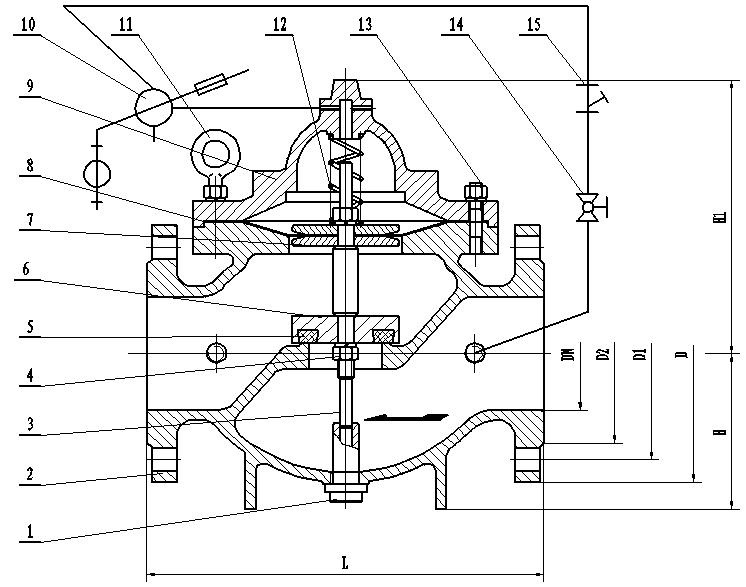

Product Structure:

100D fixed water level valve product parameters:

Serial number

Name

Material

1

Screw plug

Carbon steel

2

Body

Cast iron, cast steel, stainless steel

3

Stem

2Cr13

4

Nut

Carbon steel, stainless steel

5

Sealing ring

Nitrile rubber, EPDM rubber

6

Disc

Nodular cast iron or carbon steel

7

Diaphragm pressure plate

Carbon steel

8

Rubber diaphragm

Nodular cast iron or carbon steel

9

Bonnet

Cast iron, cast steel, stainless steel

10

Float pilot valve

(Stainless steel, copper alloy) assembly

11

Rings

Carbon steel

12

Compression spring

Spring steel, stainless steel

13

Stud nut

Stainless steel

14

Ball valve

Copper alloy

15

Micro filter

Copper alloy

Main appearance and connection dimensions of 100D fixed water level valve:

Packing & Delivery :

Packing Details:all by seaworthy plywood case and packed strongly by packing belt as below

DN

L

PN10

PN16

PN25

Z-∅d

D

D1

D2

D

D1

D2

D

D1

D2

PN10

PN16

PN25

50

205

165

125

100

165

125

100

165

125

100

4-18

4-18

4-18

65

220

185

145

120

185

145

120

185

145

120

4-18

4-18

8-18

80

240

200

160

135

200

160

135

200

160

135

8-18

8-18

8-18

100

280

220

180

155

220

180

155

235

190

160

8-18

8-18

8-22

125

330

250

210

185

250

210

185

270

220

188

8-18

8-18

8-26

150

355

285

240

210

285

240

210

300

250

218

8-22

8-22

8-26

200

420

340

295

265

340

295

265

360

310

278

8-22

12-22

12-26

250

500

395

350

320

405

355

320

425

370

332

12-22

12-26

12-30

300

530

445

400

368

460

410

375

485

430

390

12-22

12-26

16-30

350

610

505

460

428

520

470

436

555

490

448

16-22

16-26

16-32

400

700

565

515

482

580

523

485

620

550

505

16-26

16-30

16-36

450

745

615

565

532

640

585

545

670

600

555

20-26

20-30

20-36

500

810

670

620

585

715

650

608

730

660

610

20-26

20-34

20-36

600

920

780

725

685

840

770

718

845

770

718

20-30

20-36

20-41

Delivery Details:Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

Previous :

800X differential pressure bypass balance valvenext :

Y43X fixed proportional pressure reducing valveIf you are interested in our valves and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

Copyright © 2024 Tonglu Yongxin Valve Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported